10 Jan Choosing the Best Dot Peen Marking Machine

Multiple industries are legally required to label machinery parts across the supply chain. With stricter government regulations coming into play, this is becoming even more of a necessity to prevent counterfeit products and maintain quality assurance. Dot peen machines provide an effective way to permanently mark equipment with serial numbers, barcodes, logos and more.

As equipment materials vary greatly, finding the best making solutions for your needs is paramount. Our guide will help you discover which dot peen machine is best for your applications so you can integrate this technology easily.

What Is Dot Peen Marking?

Dot peen marking involves imprinting small, consecutive dots on a specific material. The process starts with an operator using a controller to program the desired design into a dot peen machine. Once in operation, the device will maneuver a carbide or diamond pin in the specified pattern. The result: durable and legible markings to identify product components accurately.

While not all materials suit this marking method, it is ideal for plastics and most metals, such as aluminum, brass and copper. For businesses that need to label large product quantities, dot peen machines offer one of the best marking solutions.

Modern dot peen markers include user-friendly software to enable you to adjust marking depth and make the process as efficient as possible. There are two common types of automated dot peen markers that you’ll come across as you shop around:

- Electromagnetic dot peen markers: These are the most commonly used markers thanks to their ease of use, impressive durability and high quality of markings they produce.

- Pneumatic dot peen markers: These markers use an air compressor to power the marking stylus. They’re affordable and ideal for businesses with low-volume and light-duty marking work.

Choosing the Right Dot Peen Machine for Your Applications

Most industries have a need for dot peen machines, but their applications are significantly different. Here are some of the most common ways businesses use these devices:

- Health care: From metal surgical equipment to plastic syringes, all medical instruments need permanent labels to comply with government regulations. Dot peen machines enable health care manufacturers to inscribe legible markings on instruments of all materials. This ensures a reliable way to track instruments from the manufacturing stage through to patient use.

- Aerospace: The combustion section of a jet engine can reach temperatures of approximately 3,000 degrees Fahrenheit. Dot peen machines ensure that identifications on metal aerospace components withstand these high-heat conditions.

- Automotive: A car is the sum total of thousands of parts, often made by different manufacturers. With the help of a dot peen machine, you can identify and track each one of these components.

- Construction: Tools and materials used in this industry consist of hard metal, wood, plastic, rubber, vinyl and more. Dot peen marking provides a universal way to label all construction parts.

- Firearms: Manufacturers need to identify each element of a gun for legal purposes. Dot peen markings are impossible to remove, making this the ideal way to label firearm parts.

In these common industry applications, the material might be soft or hard, flat or curved. It’s important to consider these aspects in your dot peen machine purchasing decisions to ensure the best results.

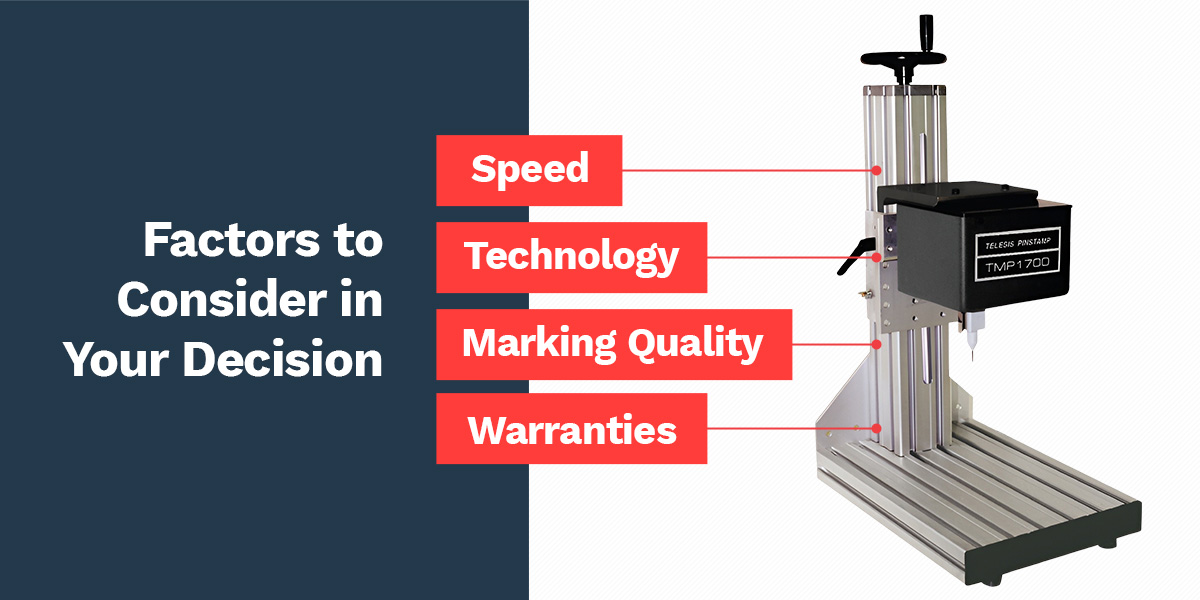

Factors to Consider in Your Decision

A dot peen machine is a significant investment, so you want to make the right choice to ensure you achieve a return on investment. Here are some important factors to consider when you make your purchase.

Speed

The manufacturing process is a relay of tasks timed perfectly to reach daily targets. When one stage of the process is out of sync, production slows down or comes to a grinding halt. Dot peen machines provide a reliable way to keep your manufacturing process running smoothly, as devices consistently produce between four and eight characters per second. While faster dot peen machines may be more expensive, they give companies working on tight assembly lines a strong competitive advantage.

Accuracy

With product identification marking, accuracy is of utmost importance. It’s even more critical if you need to mark sensitive products or machine parts. Your dot peen marker should guarantee high-quality, accurate markings with linear guides and high-precision stepper motors. These features ensure smooth lines and high accuracy and reduce the risk of errors or distortion.

Your choice of dot peen controller determines the quality and accuracy of your markings. Advanced controllers allow you to make precise adjustments to text input to achieve high levels of accuracy and customization. They also have user-friendly full-color visual touchscreens that are impact-resistant and can handle the harsh conditions in a factory.

Technology

Another factor to consider is your existing technology system when comparing dot peen marking machines. For example, if your company uses Windows, ensure the machine you choose is compatible with this system. This helps you integrate the device more quickly and eliminates the need to purchase other software solutions.

In addition, some software solutions ensure greater marking accuracy. By using barcode scanning systems, you can insert precise marking data to ensure there are no costly errors.

Marking Quality

The purpose of dot peen machines is to inscribe identifying data onto components clearly, yet not all devices are equal. Consider using a supplier that provides samples of peen markings on materials you use so you can assess the quality before you purchase.

Understand the Material You Are Using

Dot peen marking is most suitable for rigid materials such as hard plastics and metals like stainless steel, aluminum and other malleable metals. The markers are fast and efficient when marking these tough materials but significantly slower when used to engrave delicate or fragile materials. Dot peen marking is not recommended for use with brittle plastics, ceramics, wood or glass.

The substrate thickness determines the ideal marking depth and the kind of stylus you’ll need. Thick stylus needles create easily identifiable, deep marks on thicker materials. You can go for stylus tips with thinner needles if marking thin but rigid materials.

Warranties

If you’re using your dot peen machine day in and day out, you want to ensure it will stand the test of time. A manufacturer’s warranty gives you peace of mind, but also pay attention to the construction and proposed longevity of the device. Paying more for a high-quality machine at the onset decreases the likelihood of downtime and costly replacements.

Plan How to Integrate Your Dot Peen Machine

Choosing a dot peen machine suited to your applications is your top priority, but you also need to take into account post-purchase factors. Consider these aspects when weighing up your options.

Maintenance Needs

In comparison to other marking solutions, dot peen machines require less maintenance. However, regular cleaning and lubrication are still needed for your device to perform at its best.

When researching your dot peen machine options, determine how frequently you will need to service your device. This will ensure you know how to keep your machine performing optimally and whether regular services are necessary to retain the warranty. Consider choosing a supplier that will service your machine at your workplace so you do not need to send your machine off and incur excessive downtime.

Get the Best Marking Solutions From Telesis Technologies, Inc.

As a leading provider of dot peen machines, Telesis Technologies, Inc. makes it our mission to help clients find the best device for their applications. This enables you to seamlessly integrate your chosen dot peen machine with your existing software and get to work immediately.

Clients can explore two superior dot peen machine product lines to meet their unique needs and budget. Our patented PINSTAMP® dot peen machines are renowned for their innovative floating pin technology, allowing you to reach new levels of efficiency. Professionals in every industry also trust our BenchMark® dot peen machines for exceptional daily use.

Are you ready to revolutionize your assembly line with reliable dot peen machines? Contact our experienced team today for more information, or request a free marking sample to see how our technology will complement your applications.