26 Jun Guide to Dot Peen Marking

Jump To:

Many industries use marking machines to serialize their products or mark them with essential information, such as barcodes, dates, times or business details. Many different marking systems and methods are available, but dot peen marking is one of the most common techniques for industries that use metals, composites, hard plastics and other rigid materials.

Dot peen marking can help businesses mark their products or components with essential information, whether serial codes to keep track of materials or information to prevent theft. Dot peen markers can go faster and deeper than other marking tools, making them ideal for many industries.

What Does Dot Peen Marking Mean?

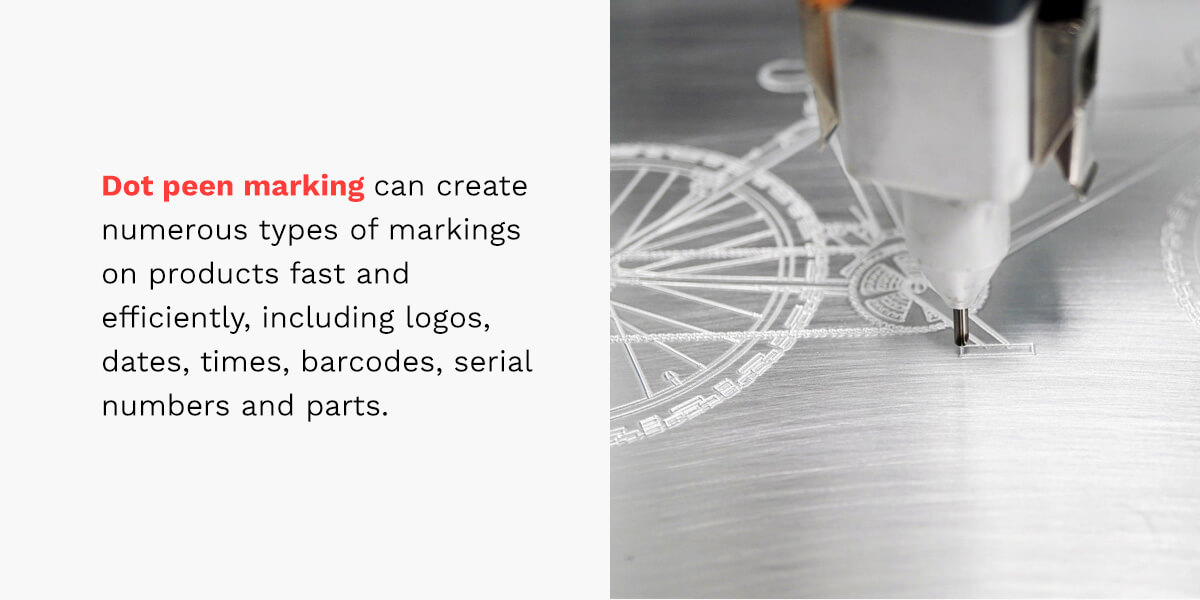

Pin marking, more commonly known as dot peen marking or pin stamping, refers to a system that makes permanent, deep impressions on various materials, including plastics, metals and other hard surfaces. Dot peen marking can create numerous types of markings on products fast and efficiently, including logos, dates, times, barcodes, serial numbers and parts. This process often uses a powdered metal or carbide pin to mark the chosen material.

Types of Dot Peen Marking Machines

Normal dot peen engravers also have two types of designs — electromagnetic and pneumatic. The machines utilize interchangeable marking pins that quickly change the work mechanisms based on the operator’s requirements. Normal dot peen engravers work slower when marking delicate or fragile materials and work faster when marking tough or rigid surfaces.

A dot peen marking machine is used to imprint materials with a series of indentations to form permanent markings. This machine is most frequently used in industrial manufacturing applications when manufacturers need to mark products permanently. Industry standards or legal regulations could require permanent marking instead of printed labels, making a more durable type of marking necessary. Other types of marking equipment, like handstamps and etching pens, are not as efficient and might create poorer-quality markings.

Dot peen marking machines are powerful and versatile enough to mark on a wide range of hard materials, such as structural steel, aluminum and plastics. These machines may be pneumatic or electric. Dot peen machines use a pin to strike the material, creating a succession of dots that form letters, numbers or various other patterns, including:

- Part numbers

- Serial numbers

- 2D data matrix codes

- Barcodes

- QR codes

- Company logos

Manufacturers can select from various industrial dot peen marking machines or entry-level dot peen machines, which are ideal for smaller applications. The advantage of the industrial dot peen machines is their ability for greater depth and higher speeds—in addition, some with their multi-pin technology that enables faster operation. For example, the TMM5400 Dot Peen has eight individual pins and can mark up to 16 characters per second. Both industrial and entry-level dot peen marking machines can be enabled for benchtop use, while industrial machines integrate seamlessly into a production line.

Many types of dot peen marking machines are available, and it’s helpful to understand the difference between them to know which would best suit your applications. Below are the many options for dot peen marking and how they work:

Vibro Peen Marking Devices

These devices are versatile and capable of marking different metal materials. Vibro peen marking systems utilize a vibrating stylus made of carbide that helps create permanent, precise markings that ensure traceability and legibility.

This dot peen machine type is popular in manufacturing, aerospace and automotive industries. Vibro peen marking devices are a low-maintenance and cost-effective solution for quality control and part identification. You can customize these devices for your applications, and they have a user-friendly interface.

You can use these devices in various ways, including:

- Creating marks on soft metals to ensure quality

- Marking metal items to help with identification

- Marking metal to indicate purity and grade

Note that vibro peen marking devices aren’t as accurate as normal dot peen marking options — they may create inconsistently spaced and deep dots.

Pneumatic Dot Peen Marking Devices

Pneumatic marking devices are used to mark metal surfaces or parts. As a result, pneumatic dot peen devices are best used in casting, stamping, forging, rolling mills and other applications. These devices create permanent marks that secure a product’s identity, which can help prevent theft in various industries. Pneumatic dot peen marking machines have become more prevalent in numerous industries to prevent the theft of valuable goods. Some other benefits of these devices include:

- Controllable marking speeds using software

- Short marking strokes

- Access to air pressure or foot pedals to make the device faster and stronger

- Ability to mark or serialize thin walls, small parts and deep cavities

Pneumatic dot peen markers with floating pin technology can mark irregular surfaces and work on materials with angles.

Metal Tag Engraving

Metal tag engravers are ideal for working with tags made from different metals, including aluminum, copper, iron and brass. These machines are suitable for industries that need to mark tags, whether for employees or products, which is useful in construction, shipbuilding, military and other industries.

Dot peen tag engravers make it easy to label various items from different materials, including metal, plastic and wood. You can use these machines to code different items, including alphabets, numbers or a combination of both, to help identify products in batches.

These machines comprise three main parts — the engraving head, the hex part and the engraving piece. The engraving head moves based on the software’s generated content.

There are a few different types of metal tag engravers, including:

- Fully automatic engravers: These engravers work at high speeds and require little operator intervention, helping achieve precise engravings for large operations.

- Manual engravers: These engravers are cost-effective and straightforward for small engraving tasks requiring a hands-on approach.

- Semi-automatic engravers: These require partial manual and automated operations to increase precision and efficiency.

- CNC engravers: These engravers use computer numerical control, making them more accurate when creating complex designs, so they’re ideal for detailed marking applications.

Benefits of Dot Peen Marking Machines

Dot peen marking has several advantages over traditional methods, including punch and die or hand stamping. Dot peen marking also has benefits over modern systems, including inkjet and chemical marking or etching. Some of these benefits include:

- Durability: Dot peen devices help create durable, permanent marks on materials, which makes these machines ideal if you need deep engraving. These systems are suitable for marking tough surfaces and provide a more durable result than other marking systems.

- Speed: Dot peen systems can mark materials faster than other marking systems, helping you mark your products or parts quickly and improve efficiency. Dot peen marking systems are ideal for those looking for a quick, accurate and quality marking solution.

- Portability: You can find dot peen marking machines in different designs, including desktop or portable models. Each device has unique capabilities and features. Portable dot peen marking machines are lightweight, allowing you to take them to different locations as needed. Portable machines also make it easier to mark parts of products with large surfaces or if you need to make complex designs.

- Flexibility: Dot peen machines are compatible with various materials, making them flexible devices for varied materials. You can use these machines with metals like copper and aluminum, different plastics and any other materials with a hardness under 62 HRC.

- Options: Dot peen marking machines can be either pneumatic or electric. Each type of machine has different benefits and features, and you can choose the one that allows you to work with your desired material.

Applications for Dot Peen Marking Machines

Dot peen marking machines are useful across many industries, helping create durable, permanent markings on various materials and products. Some of the most popular industries that use these machines include:

1. Forging Industries

Forging industries utilize dot peen marking machines to put identifying marks on different products, such as structural steel, iron castings and forged products that are sent away for heat treatment or finishing. Forging companies use dot peen marking as a backup method to transfer part numbers.

2. Rolling Industries

Rolling industries utilize dot peen marking machines to place identification marks on rolled metal sheets. While other types of marking systems can be used in these industries, dot peen marking is the preferred method. These machines help rolling industries easily transfer information onto the product surface without leaving signs of impressions.

The only factor to consider when using dot peen marking machines in the rolling industry is that they can remove or damage surface metals, so it’s essential to be cautious when using these machines with certain metal products.

3. Casting Industries

You can use dot peen marking machines in the casting industry to put identification marks on castings, which is ideal for making it easier to identify specific components during production cycles or marking components to prevent theft. Dot peen marking systems can draw part numbers or logos on castings.

4. Purchasing Industries

Dot peen marking places identifying markers on raw metal materials that are moved to factories from vendors and suppliers for additional processing. These markings assist manufacturers with delivering catalogs, receipts and purchase orders so they can look up orders and prevent errors.

5. Stamping Industries

The stamping industry uses many metal parts and metal-forming processes. In this industry, steel dies hit blanks repeatedly until you achieve your desired shape. Sometimes, these blanks are pressed from ingot or sheets at high pressures, which can cause them to have uneven markings or distortions.

Dot peen marking machines can help prevent these errors by marking products with identifying marks on blanks before fully forming. Once these markings are placed on the blank’s surface, they will be noticeable when you examine stamped products under the proper lighting conditions after finishing processes. These markings help you make the correct stamping impressions to prevent distortions or uneven markings.

6. Electrical Industries

Dot peen marking systems are used in the electrical industry to create identifying marks on metal components before you assemble them into electrical devices. These marks make it easier to avoid mistakes during the assembly process. Additionally, these marks can help during repairs by ensuring the person repairing electrical devices isn’t blindly searching for the right component or choosing the wrong one that may happen to fit, helping improve productivity and efficiency.

7. Manufacturing Industries

Dot peen marking machines are used in the manufacturing industry to engrave marks on different metal parts before they go through additional stages of manufacturing processing, such as machining, casting, forming or forging. Using these devices helps prevent errors in product-level inventorying and makes it easier for manufacturers to maintain control of their products.

How to Choose the Best Dot Peen Marking Machine

If you need a dot peen machine for your operations, picking the right one is essential. Consider the factors below to help you make the best choice when buying your device:

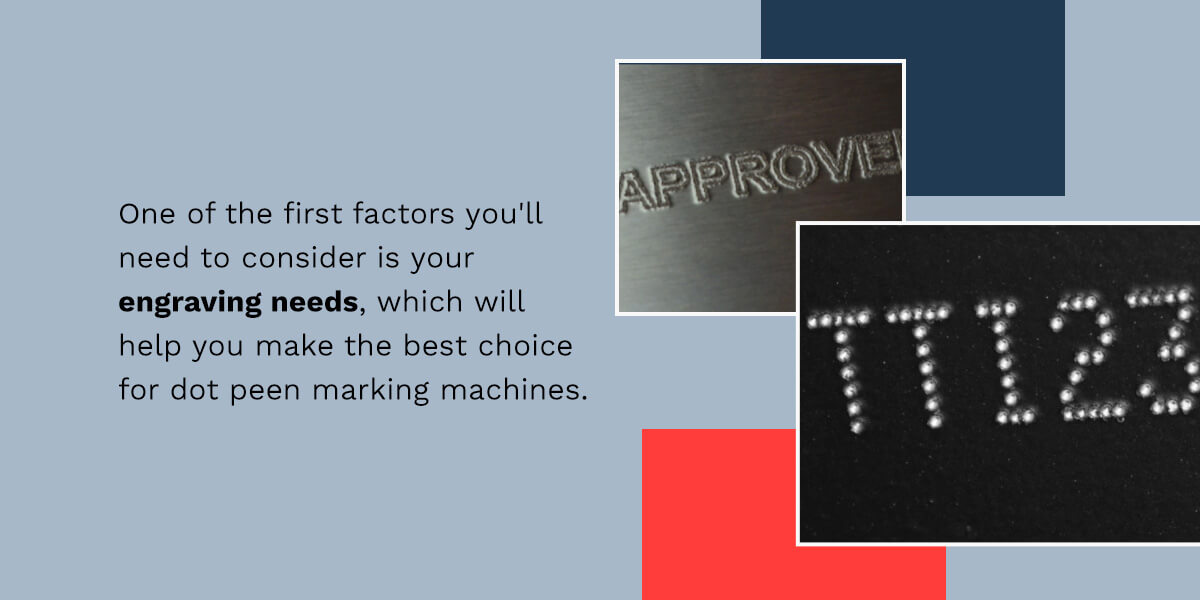

Engraving Needs

One of the first factors you’ll need to consider is your engraving needs, which will help you make the best choice for dot peen marking machines. You’ll want to ask yourself the right questions, such as:

- What material do you need to mark?

- Do you need automated or computer-controlled operations?

- How big do you need your engravings to be?

- Do you need to mark multiple parts simultaneously?

Answering these questions can help narrow down your choices so you can choose a machine that’s effective for your applications.

Remember, dot peen marking machines work best with specific materials, such as aluminum, hard plastics and stainless steel. These machines are more suitable for some industries over others. Dot peen machines aren’t necessarily useful with glass, wood, brittle plastics or ceramics. You would need to use another marking method for these. It’s essential to perform the proper research to ensure your current and future projects will involve materials that can work with a dot peen marking machine.

You’ll also want to consider your ideal marking depth. If you need a deeper mark, you’ll need a thicker marking needle and a stable structural configuration to ensure it can withstand higher intensities. If you need fast marking, only specific dot peen marking machines will give you precise, identifiable marks with quick markings.

Machine Design, Features and Durability

Another factor to consider is the dot peen marker machine’s features and durability. Ideally, you’ll want to choose a device that can handle high-performance operations accurately while protecting your materials or product from damage. You’ll want to consider the construction of different models, their working life and their portability, if needed. You may also want to find a machine with low noise levels to make your work environment more comfortable.

There are several factors to consider when looking for a quality machine:

- Integration degree: Many dot peen marking machines must be connected to external computers. If you choose one of these machines, the device will likely be connected to a computer using a USB, which can cause poor connectivity and poor signal. Consider a machine with all its components integrated. Selecting one of these machines ensures your device stays intact during operation and storage, helping extend its useful life.

- Marking accuracy: Accuracy is essential with dot peen marking machines, especially if you need the device to mark sensitive parts. You’ll want to look for a machine with high accuracy to reduce the risk of error when marking your components.

- Durability: Many products in industries like construction, automotive manufacturing, aerospace and defense must withstand harsh conditions. Dot peen marking machines create durable designs by striking the product’s surface to a specified depth. This technique creates marks that last and helps prevent counterfeit products.

Maintenance and Service Needs

Before buying or using a dot peen marking machine, ensure it can handle regular wear and tear. Additionally, you’ll want to understand the machine’s expected maintenance and how long the parts will last until they need service or replacement, including springs, marking pins and marking tools. Once you know what steps you need to take to maintain your dot peen marking machine regularly, you can create a maintenance plan and choose a device that can perform as long as possible before it needs service.

You’ll also want to choose a dot peen marking machine manufacturer that offers service requests for any repair work you need down the line.

Software Compatibility

When choosing a machine, find one that is compatible with whatever software you want for your design and production processes. You’ll want to look for machines that can support your ideal system, allowing you to move designs from your software to the device easily. Your chosen machine should be able to work with the file type and size you need. A compatible engraving device will benefit your business since it can reduce your need to invest in new software, minimizing your overall costs.

Price Range

Another factor to consider is your budget and the price range for different models. You don’t want to rush to buy a machine that may not have all the necessary features or has ones that wouldn’t be useful for your business. You’ll want to consider all the costs when buying a machine, including the price of the equipment and maintenance costs. However, you don’t want to place price above any other factors. Consider cost alongside quality and service to ensure you can get the most from your device.

Machine Operation and Control

One of the last factors to evaluate is machine operation and control. Most machines will need to be operated by software, and if you have more unique requirements, such as identification, data transmission or database storage, you may need customized software.

- The operator inputs a design: In industrial applications, the operator creates a design and programs the dot peen machine to make the correct markings on the material using the controller. The controller makes operation simpler when a manufacturer needs to mark a high quantity of items with the same markings. A dot peen marking machine’s programmability enables crisp lettering and logos using clear dot patterns that humans and machines can read.

- The machine powers the pin: When the machine recognizes the design that was input, it begins powering the pin to create the marks on the material in the specified order. Dot peen marking machines are powered by springs or compressed air, with Telesis dot peen systems requiring no spring consumables and drive the pin with air force and air return.

You may also want a portable machine, especially working with large parts. Some portable models can be operated using a battery, allowing you to use them outside and in power-free locations.

Contact Telesis Technologies, Inc. for Your Dot Peen Marker Needs

If you’re looking for dot peen markers for your business, Telesis Technologies, Inc. has what you need. We offer many Dot Peen marker machines, including PINSTAMP® and BenchMark® models. We also offer portable models, ensuring you can access the machine you need for your applications. Our equipment is safe to use and can efficiently engrave your products, whether you want serial numbers, logos, dates, times or other information.

We constantly seek to bring revolutionary products to the market to meet your needs. Our equipment is built to last, helping protect your investment. You can contact your local team to find out more or purchase the equipment you need from our website.