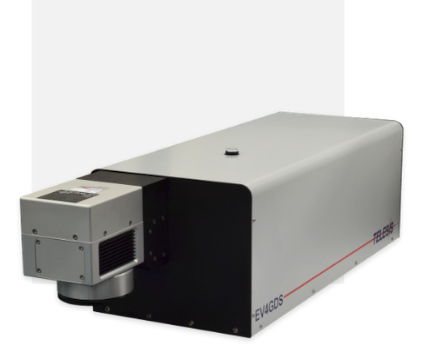

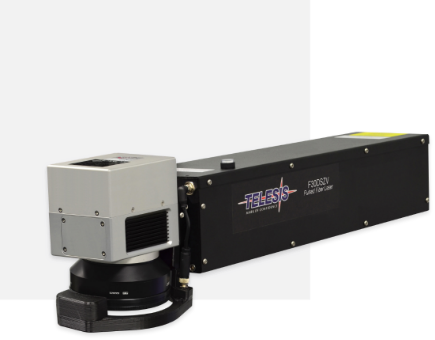

Advanced Laser Marking Solutions for Medical Devices

Clear, permanent identifying markers are vital for medical equipment. Telesis Technologies, Inc. provides laser engraving equipment that boosts safety and reliability. Our solutions use advancements like AI and robotic integration to achieve precise markings so you can continue supplying superior medical equipment.