09 Jul How Dot Peen Marketing Ensures Compliance with FDA Regulations in the Medical Industry

Compliance and traceability are crucial in the medical device manufacturing industry. From the initial stages of production to packaging and distribution, components must be marked to meet the United States Food and Drug Administration (FDA) requirements and fit into workflows.

Dot peen marking is a reliable and practical solution that meets requirements with durability, precision and adaptability. Explore how this technology supports regulatory conditions below.

Medical Part Marking Laws

Medical device manufacturers face stringent identification and traceability requirements under the FDA. One of the most important mandates is the implementation of the unique device identification (UDI) system. The UDI system provides each medical device with a unique code that includes a device identifier (DI) and a production identifier (PI) of devices in distribution and use.

The DI points to information about the model or version of a device, while PI contains production details such as lot number, expiration date and serial number.

The UDI system supports:

- Patient safety: The system allows for identifying and removing recalled devices from clinical settings. This reduces the risk of using expired or counterfeit products and provides clear visibility into device use for patient medical records and surgical histories.

- Supply chain efficiency: Having unique identifiers allows for inventory control through barcode scanning. The system improves accuracy in restocking and device selection, which may support purchasing and logistics coordination.

The FDA mandates that all medical devices distributed in the U.S. bear a UDI on the device label and, where applicable, directly on the device.

The UDI must:

- Be presented in human-readable and machine-readable formats

- Remain legible and intact through the device’s lifespan and usage conditions

- Be submitted to the Global Unique Device Identification Database (GUDID)

How Dot Peen Marking Meets Medical Part Marking Standards

Dot peen marking helps device manufacturers comply with international and domestic part marking requirements. Here is how this technology aligns with industry benchmarks.

Provides Durability and Permanence

Medical devices are often exposed to harsh sterilization methods, repeated usage and long life cycle applications. Dot peen marks are indented into the material surface, creating a permanent impression that can’t be removed, degraded or rubbed off.

This durability makes dot peen ideal for components subject to:

- Autoclaving, sterilization or chemical cleaning

- Mechanical wear

- Harsh storage or transportation conditions

Adheres to Regulatory Standards

Dot peen systems can be configured to meet specifications outlined in standards, such as the International Organization for Standardization (ISO) 13485, which governs medical device quality systems, biocompatibility and sterilization practices. Machine-readable codes, such as data matrix or alphanumeric identifiers, can be generated to comply with:

- ISO and the International Electrotechnical Commission (ISO/IEC) 29158 for symbol quality

- Global Standards 1 (GS1) standards for healthcare traceability

Meets CE Marking for Medical Devices

For devices entering the European market, Conformité Européenne (CE) marking under the Medical Device Regulation requires traceability and compliance with UDI requirements similar to those enforced by the FDA.

Dot peen marks offer:

- Identification for Class I to III devices

- Compliance with the European Union (EU) Medical Device Regulation Annex VI Part C

- Compatibility with post-market surveillance and field recall protocols

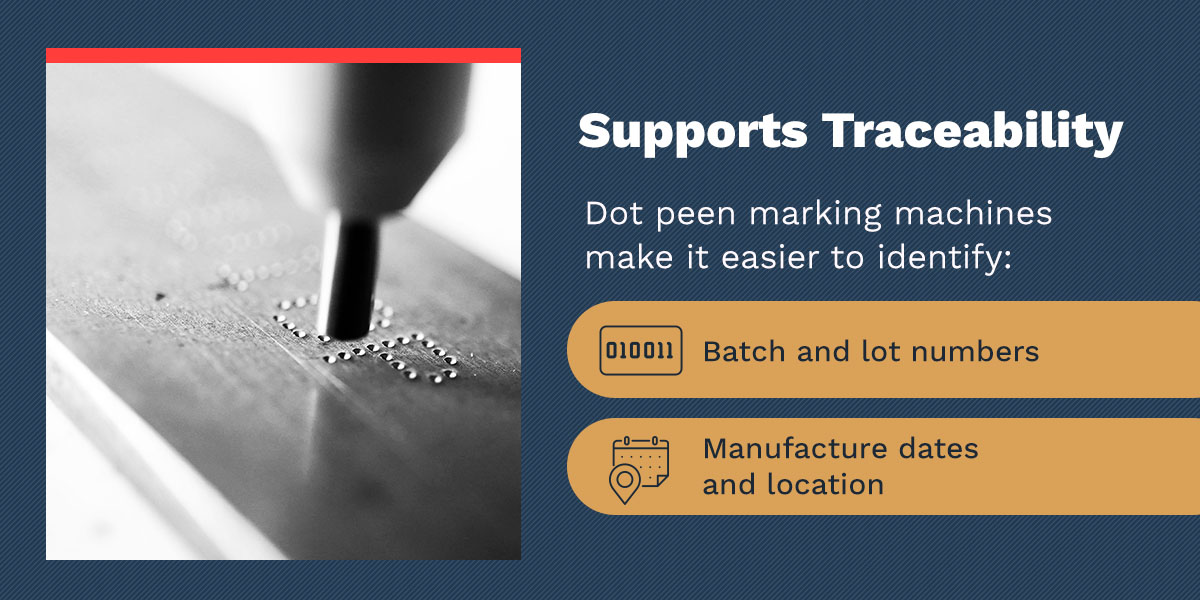

Supports Traceability

Traceability in the medical industry is a core requirement. Dot peen marking machines make it easier to identify:

- Batch and lot numbers

- Manufacture dates and location

This granular marking capability ensures integration into inventory management systems. In the event of a device recall or defect investigation, stakeholders can trace the product history to limit risk and reduce patient exposure.

Ensures Legibility

Dot peen systems produce clear text, logos and codes that are human and machine readable. The ability to adjust speed and character sizing allows for precise control over contrast and depth, which is essential when marking small or intricate parts.

Even on curved or irregular surfaces, dot peen heads can maintain legibility. Manufacturers can adapt to the surface geometry, ensuring each mark meets quality verification requirements. This level of legibility supports visual inspection and systems used in production lines.

Advantages of Dot Peen Marking for Medical Devices

Dot peen marking has various capabilities suitable for the requirements of medical device manufacturing. Explore the top five benefits of using a dot peen marking machine:

1. Versatility to Mark Various Materials

Medical devices are manufactured from various materials, including plastic and hardened steel. Dot peen marking can produce clean, readable marks across this diverse material set. For instance, titanium implants can retain low-stress marks that do not compromise structural integrity. Stainless steel instruments can be marked with clarity without distorting surface finishes.

This versatility minimizes the need for different marking systems across the production line.

2. Highly Precise

Some medical components are intricate and contain critical features. Dot peen technology offers micrometer-level precision, ensuring that each mark is placed where intended without affecting surrounding geometries or functional surfaces.

These capabilities can accommodate:

- Fine-pitch serial numbers and 2D Data Matrix codes

- Complex alphanumeric characters

- Surgical tools and implantable devices

3. Flexibility in Marking Complex Shapes and Surfaces

Not all devices are flat or easily accessible. Dot peen systems can adapt to curved, cylindrical, angled and difficult-to-access surfaces thanks to the floating pin technology. Some dot peen markers contain a double strike feature to accommodate depth requirements and a programmable Z-axis for varying part heights.

4. Customizable for Project Requirements

Each medical device production line is unique. Manufacturers can customize dot peen marking machines based on character size, font and mark layout, as well as marking depth and speed.

5. Integrates With Workstation Systems

Dot peen marking machines are flexible and portable, making them ideal for fixed workstations or mobile setups. Whether you are operating a high-volume assembly line or require capabilities that can move between work cells, the technology adapts to your needs.

These systems can integrate seamlessly with manufacturing workflows through:

- Ethernet and serial connectivity

- Compatibility with programmable logic controllers (PLCs) and host computers

Partner With Telesis Technologies, Inc. for Dot Peen Marking Needs

When you need marking solutions that meet FDA requirements, the team at Telesis Technologies, Inc., can help. Our dot peen systems offer fast, accurate, safe and permanent marking on various medical-grade materials. You can mark flat or irregular surfaces, with full control over depth and character configuration. These systems integrate into production lines or stand-alone workstations.

Every system comes with Merlin software, enabling you to handle various requirements with ease. Our team provides support, product customization and integration services. With worldwide sales and service coverage, we offer support wherever you operate.

Talk to an expert today to learn more.

Linked Sources:

- https://telesis.com/dot-peen-marking-guide/

- https://www.fda.gov/medical-devices/unique-device-identification-system-udi-system/udi-basics

- https://www.fda.gov/medical-devices/unique-device-identification-system-udi-system/global-unique-device-identification-database-gudid

- https://telesis.com/what-is-dot-peen-marking-machine/

- https://telesis.com/dot-peen-markers/

- https://www.iso.org/standard/59752.html

- https://www.iso.org/standard/87123.html

- https://www.gs1.org/industries/healthcare/standards

- https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=uriserv:OJ.L_.2017.117.01.0001.01.ENG

- https://pmc.ncbi.nlm.nih.gov/articles/PMC8781702/

- https://www.medical-device-regulation.eu/category/z-annex-vi-part-c-the-udi-system-part-1/

- https://www.nsf.org/knowledge-library/post-market-surveillance-what-you-need-to-know-to-ensure-patient-safety

- https://telesis.com/why-were-different/

- https://telesis.com/contact-us/