23 Feb Types of Laser Engravers

Jump To:

Let’s explore the different types of laser engravers and marking processes, the industrial applications of the technology and the materials compatible with these processes.

What Is Laser Engraving?

Laser engraving allows you to creatively design the material with various patterns, shapes and writings. The design is durable and can withstand wear and tear and several surface treatments.

What Are the Types of Laser Engraving Machines?

There are main types of engraving machines, each with unique specifications and functions. These are:

- Fiber laser markers: These are the most versatile laser engraving machines due to their ability to adapt to various applications, from automotive manufacturing to security and medical industries. Fiber laser markers are primarily used on plastics and metals. They require minimal maintenance and eliminate consumables from the marking process.

- CO2 laser markers: CO2 laser markers are excellent for heavy-duty applications and labeling packing. They remove the need for consumables and speed up processing. They can mark up to 1,300 characters per second in automated environments.

- Green laser marker: The green laser, often called a “cold” marking laser, marks without generating heat capable of damaging sensitive and fragile materials. You can use them for keeping precious metals such as gold, copper and silver. They’re also suitable for engraving electrical components, magnetic cards, printed circuit boards, computer chips and foil.

- Vanadate laser markers: The vanadate laser marker offer improved beam quality, higher peak power and increased depth focus compared to fiber lasers. You can also use it for marking heat-sensitive materials such as foils, plastics, silicon and metals. Use vanadate laser markers for applications that require high consistency.

- UV laser markers: UV laser markers are used for marking a wide range of materials, especially where heat-affected zones aren’t allowed. They’re suitable for marking plastics and silicon without additives and can mark glass with reduced risk of micro-fracture. The beam makes precise micro-marking with sharp resolutions.

Dual-head laser system: The system allows you to control two lasers from a single point. Dual-head lasers have double the capacity of one controller, increasing the throughput in repetitive applications. They also save space, reduce handling and increase marking efficiency.

Class 1 laser enclosures: These engraving machines are constructed with industrial-grade materials, making them suitable for a wide array of shapes and sizes. Class 1 laser enclosures can accommodate large and small workspaces and part sizes. They’re durable, safe, flexible and efficient.

Unique Laser Marking Processes

Besides the three main types of laser engravings, understanding the different laser marking processes can help you decide which laser marking system best fits your industry. These processes are carbon migration, annealing, foaming and coloration.

1. Carbon Migration Laser Marking

The carbon migration process involves heating the metal or alloy, causing it to chemically bond with the carbon molecules. This brings the carbon properties to the material’s surface, leaving dark laser markings behind.

The carbon migration process is faster because it focuses a high amount of energy in small areas at a rapid pace. You can use the technique for metals such as stainless steel, steel and titanium. It’s helpful in various industries, including automobiles, aerospace, jewelry and metalworking.

2. Annealing Laser Marking

Annealing laser marking is an oxidation process where heat is applied to the material’s surface without high aggression. The process leaves behind a clean black mark, which can vary between red, green and yellow depending on the temperature.

Annealing is typically slower because it relies only on heat to bring the carbon to the material’s surface to make the markings. It’s best to allow the metal to cool down after heating it.

Annealing laser marking is used in the medical industry for internal tracking and branding. It works on many metals, including iron, titanium, steel and stainless steel.

3. Coloration Laser Marking

The coloration laser marking process produces color to metal or plastic by heating specific surface portions depending on the anticipated outcome. You can achieve the desired shade or color by controlling the pulse frequency and width.

You can use the foaming process for coloration on plastics, as well. Manipulating polymers within plastics can result in varying wavelengths of colors, usually ranging from infrared to ultraviolet. On the other hand, metal coloration uses an oxidation process applied to treated or untreated surfaces. The process offers multiple color schemes, allowing you to get creative with the design.

Lasers used for coloration marking operate at varying speeds, power levels and frequencies.

What Are the Applications of Laser Engraving?

Laser engraving is applicable in various industries, including the following:

- Aerospace

- Automotive manufacturers and suppliers

- Construction and housing

- Medical supplies and devices

- Electronics

- Military and defense

- Jewelry and awards

- Oil and gas

- Consumer goods

The list provided above is by no means exhaustive. The technology is helpful for many purposes, including barcodes, logos and brands, signs, cabinetry, gunstock and data plates. In some cases, laser engravings are valuable for compliance purposes.

What Materials Are Compatible With Laser Engravings?

The technology works on a wide range of materials, such as:

1. Leather

Leather has a positive response to laser engraving. This makes it ideal for creating brands, logos and other inscriptions on belts, shoes, bags, leather jackets, wallets and purses. Laser engravings are suitable for multiple leather types, including:

- Suede

- Natural

- Synthetic

- Bonded

- Nubuck

- Alcantra

- Napped

- Full-grain

2. Wood

Laser engraving works perfectly on wood. Besides producing some of the finest results, the technique is suitable for several wood types. Examples include:

- Cork

- Veneers

- Natural wood

- Solid wood

- Plywood

- Chipboard

- High-density fiberboard

- Medium-density fireboard

- Multiplex

3. Paper

For varying purposes, you can create laser marks on several paper materials. Laser marking offers a premium touch when designing business cards or other customizable paper products. The technology works with multiple paper types, such as cardboard, fine paper and art paper.

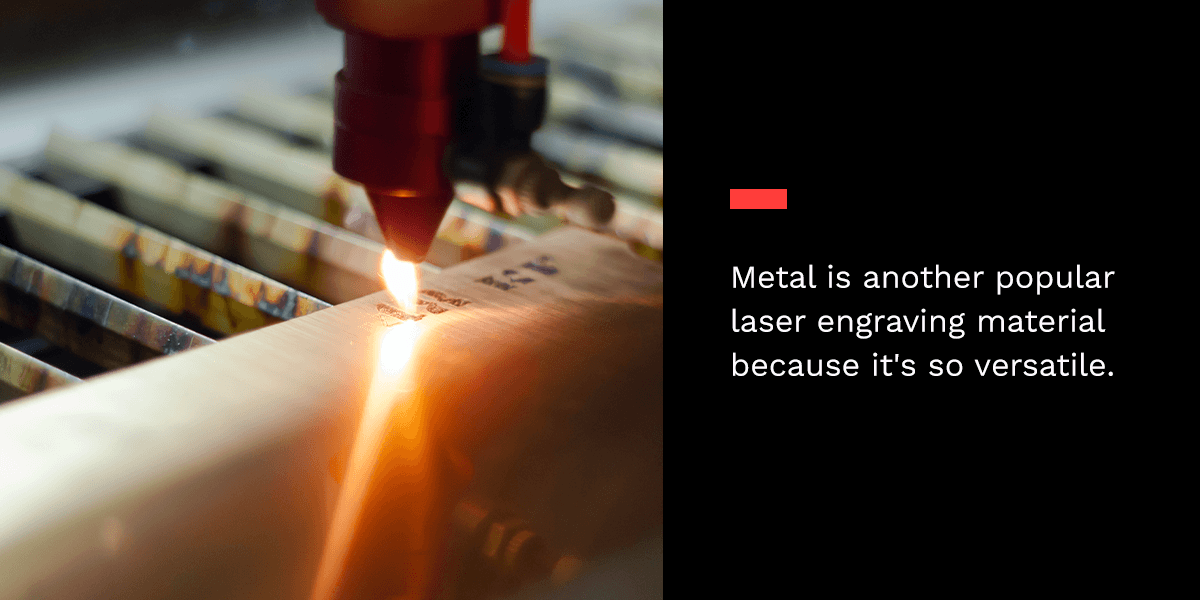

4. Metal

Metal is another popular laser engraving material because it’s so versatile. Examples of the best metals for laser engraving are:

- Gold

- Titanium

- Copper

- Brass

- Stainless steel

- Steek

- Aluminum

- Iron

- Silver

5. Plastic

Due to the various laser machines and technologies available, plastic markings have become renowned. Laser markings apply to plastic types such as:

- Polyethylene

- Silicone

- Vinyl

- Acrylic

- Polycarbonate

- Polyester

6. Glass

Glass laser marking is ideal for several glass products, including mirrors, windows, wine glasses, champagne flutes, crystals and bottles. The process is straightforward when you use the rotary engraving attachment. The unique feel laser engravings add to glasses make them perfect for various celebrations and gifts. Today’s technology makes it possible to create several inscriptions on glass without microfractures.

7. Stone

Industries that work with stones can also benefit from laser engraving technologies. Other associated materials that use laser technology are ceramics, bricks, porcelain, marble, granite and natural stone. With the correct settings, you can create concave, convex and laser ablations in the form of texts, logos and other images on stone products.

Learn More About Laser Engravings With Telesis

Laser engraving technology is constantly evolving, offering a myriad of techniques for achieving multiple high-quality outcomes. This requires you to get closer to the development within the laser industry to help you integrate the best modern solutions into your business. The easiest way to do so is by partnering with a solutions provider with expertise in laser technology.

Telesis Technology, Inc. is equipped with the latest industry technologies, such as artificial intelligence and robotic integration, and is capable of transforming your business into a highly competitive venture. We provide solutions that add value to your business, regardless of the industry. We’re a one-stop shop that takes care of all your needs, from customization to integration.

Schedule a demo today to learn more about our product line and how we can integrate them into your current system.