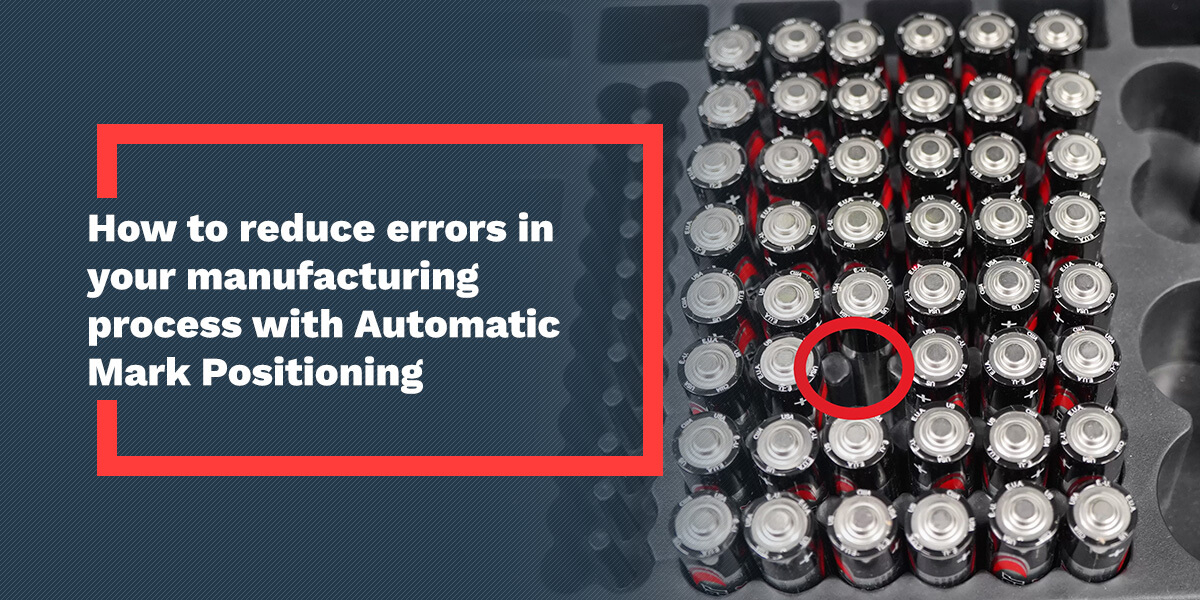

17 Nov How to reduce errors in your manufacturing process with Automatic Mark Positioning

Jump To:

The Problem and Solution

All production facilities are concerned with reducing manufacturing issues resulting from human errors and quality. Reducing errors is a very high priority. Manufacturers can prevent errors by adding traditional quality control stations to production lines. But a better solution is to utilize the Telesis’ proprietary software Merlin®. With Merlin, manufacturers can build QC and QA directly into the production process.

New advancements allow cameras to be installed inside the enclosure of the laser or externally attached to the lens. Combining vision technology and laser marking into a single station saves time, money, and space. This means production teams can find errors immediately and can stop multiple errors from continuing down the line that should be stopped and corrected.

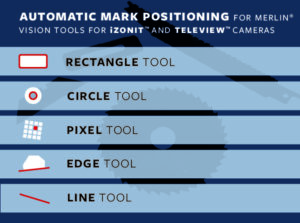

Mark Positioning

Merlin® laser programming software takes the image from the camera and intelligently finds a specified parameter. The software then aligns the mark perfectly every time without a need for a fixture or human interaction. This process can look for a circle, a rectangle, an edge or a line. The advanced positioning tool finds your part and lines up the mark even if it is not aligned properly. The software utilizes an algorithm that finds the specified key object of a circle, rectangle, edge, or line. Then, it positions the mark in the location that is offset from that key every time in any orientation.

Part Detection

Another camera tool is the pixel tool. This tool looks for a set of pixels and can use this information to determine if a part is present, out of alignment, or it can even be used to load a particular part program. When it finds a error, Merlin can direct the laser to stop, pause for adjustment, skip a serial number, load a different pattern or any other operation that is programed in the software pattern.

Telesis Technologies Solutions

Telesis has installed camera positioning and part detection for many customers. The company’s solid record of reducing scrap from human error and quality issues is unique in the industry. The investment in a Telesis Laser Marker with Automatic Mark Positioning will not only provide increased revenue and higher quality, but the customer they will receive the best customer service possible. Customers trust Telesis Technologies.