29 Jun Is Laser Marking Safe for Food Packaging?

Jump To:

Food labels are essential in the food packaging industry, ensuring you can protect and trace your products while keeping your consumers accurately informed of the contents of their packaging. Laser marking systems can create permanent marks on food and food packaging and communicate essential information to consumers and manufacturers.

Laser marking is an excellent way to mark your products with important information, such as serial numbers, QR codes and logos. Learn more about laser marking, why you should use it for your business and the many benefits of using laser marking systems for your applications.

Why You Should Use Laser Marking and Engraving on Food

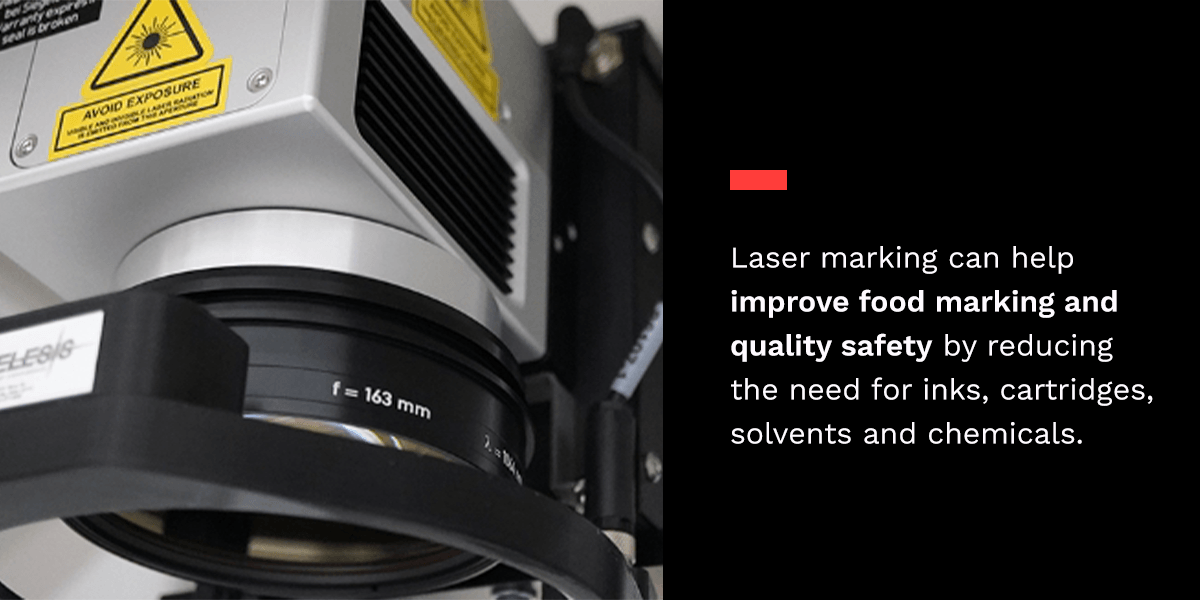

Marking and engraving food or food packaging is a safe process, since laser marking is a “light reaction” that creates contrast without harming the package or product. Laser marking can help improve food marking and quality safety by reducing the need for inks, cartridges, solvents and chemicals. Laser marking also marks directly onto food, eliminating the need for some types of packaging materials. Laser marking is a light heated, non-toxic process, ensuring that food labeled with lasers is safe for consumption.

Laser marking is also essential for traceability, which tracks produce and other perishable food through the supply chain. Tracking is necessary to reduce the risk of foodborne illnesses and recalls while building trust with your consumer base. Laser marking makes it easier to track perishable food, and you can use laser markers to put unique identifiers on your food products, such as serial numbers, bar codes and data matrix codes. Suppliers can use these markings to trace and track data, including destination within the supply chain and expiration dates.

The Process of Laser Marking Food

The process of laser marking food packaging or products starts with a CO2, Vanadate or Ultra Violet (UV) laser to create marks on vegetables, fruits and other food products. Laser marking systems can engrave various markings onto food products, including expiration dates, serial numbers, barcodes and logos. The laser marking machine will react with the top superficial layer from the product’s skin, leaving the food unaffected and intact. Some foods you can mark with lasers include:

- Apples

- Bread

- Cheeses

- Cookies

- Eggs

- Eggplant

- Lemons

- Limes

- Mangos

- Oranges

- Potatoes

These are just a few of the many food products that can use laser marking, whether you want to include a barcode or your logo. Some of the applications and their benefits include the following:

- Serial numbers: Engraving serial numbers helps suppliers safely track and trace products and their information.

- QR codes: QR codes are similar to barcodes and contain pixels arranged in a square grid. People can scan these codes with their digital devices, such as a smartphone, to receive tracking information about a food product and its specific track along the supply chain.

- Barcodes: Barcodes are a series of black and white parallel lines that represent specific numbers or characters. Distributors and retailers use barcodes to track and manage sales, inventories and reordering.

- Data matrix codes: These two-dimensional barcodes use black and white cells organized into a rectangular or square pattern. The exact number of columns and rows determines how much information the data matrix code can store.

- Logos: You can use a laser marking system to place your logo on food products, helping increase brand awareness and loyalty.

You can choose from one or a combination of these options when using lasers to mark your foods. For example, you can use laser marking systems to include your logo and barcode on your food products, helping you benefit from both applications.

Benefits of Using Laser Marking on Food and Food Packaging

As mentioned above, laser marking on food is safe, leaving the food unaffected and safe for consumption. Additionally, laser marking has many other benefits for food and food packaging, including the following:

- Permanence: Laser marking systems can deliver a permanent marking on your food or food packaging, ensuring the marking lasts from the start of the production process to the end. You can rely on your markings to remain until consumers take the food home for consumption.

- Legibility: Laser marking is highly accurate. However you choose to mark your food or food packaging, the mark will be highly legible, which is essential with serial numbers, barcodes, QR codes and logos.

- Precision marking: Laser marking systems don’t need to contact the surface, allowing them to produce repeatable and precise markings without the risk of error. Repeatable engravings are ideal when labeling food with QR codes or logos.

- Marking versatility: You can use laser marking systems to mark many different foods and food packaging materials, such as paper, plastic, wood, cardboard and silicone. The versatility of laser markings allows you to replace outdated processes to improve your food and packaging labeling applications.

- Wear resistance: Marks from lasers are durable and resistant to various environmental and operational factors without experiencing wear like other markings. For example, inkjet printing allows you to apply expiration dates and other markings to food and food packaging, but the ink can be rubbed off. Laser markings can’t be rubbed off, ensuring the permanence of your markings.

- Operational speed: Laser engravings are faster and more efficient than other traditional marking methods, helping you mark more products in less time. Laser marking systems can help improve your lead times and allow you to get products to consumers sooner.

- Minimal consumption: The laser marking process is more cost-effective and energy-efficient than other marking methods. Laser marking is also more environmentally friendly since it doesn’t rely on stickers, ink or other markings that can harm the environment. Lasers don’t produce any excess pollution and help reduce costs since you don’t have to spend extra money on new stickers, ink cartridges or other traditional marking materials.

- Better sanitation: Laser marketing is more sanitary than other methods, such as paper labeling. Laser marking allows you to create clean, crisp lines that won’t smudge like ink on paper.

- Preventing counterfeit products: Laser markings make it more challenging for scammers to alter or replicate your packaging design. Laser markings are unique and can be identified, helping deter others from trying to replicate your products.

Contact Telesis Technologies, Inc. for Your Laser Marking Needs

If you want to use laser marking or engraving for your food and packaging products, Telesis Technologies, Inc. can help. Our technology makes it easier for manufacturers and retailers to add product markings, including serial numbers, barcodes and logos.

We carry various laser engraving machines to meet the needs of your applications, including dual-head laser systems, UV laser markers and CO2 laser markers. Our team members can help you find the perfect laser marking system to meet the specific needs of your business. Contact us today to request a quote or to learn more about how our laser marking and engraving systems can help!