14 Jul What is the Difference Between an Industrial Laser and a Hobby Laser?

Lasers for Crafts and Hobbies

It started with laser pointers. For decades, people have used these devices to point at presentations, aim guns, and distract their cats. Pen-sized lasers are visible to the human eye and first made available in red. Soon after, customers could purchase green, and then

blue. The blue pointer emits the most dangerous light—even at low power it can burn paper, pop balloons, or cause serious injury to human skin.

Now, the trend is to add that blue laser pointer to an inexpensive X/Y table to create a laser burner. These burners can cut shapes and images on paper, wood, and other organic materials. Companies sell these lasers within a small enclosure or as a hobby kit to avoid the safety regulations that are associated with selling a laser system. Many brands have popped up in recent years, with DIY consumers purchasing these items.

How Safe are Hobby Lasers?

Hobby lasers are extremely dangerous. Many were not designed with safety in mind. In fact, hobby lasers are classified as Class 4 lasers. Class 4 is the highest and most dangerous classification for a laser by the FDA. Because these lasers are classified as hobby lasers, and the customer builds them, the customer can buy these lasers on many online retailers and have them shipped to their homes.

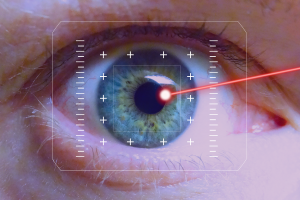

The beam produced by these lasers can easily burn your skin—but perhaps more seriously—destroy your eyes. Danger can arise from a direct hit to your skin or eyes, or from reflected light that damages human tissue.

Safety issues also arise from the material the operator is burning. Burning materials like plastics and PVC can be deadly. Many plastics burn while producing gasses that can have long term health consequences or even death. Wood may contain chemicals that are hazardous. Even paper may be coated with plastic that produces noxious gasses.

When purchasing a laser, it is critical to buy from a manufacturer that makes safety the most important part. Although there are a few manufacturers that incorporate minimum safety features (the very minimum required by law), some safety features are only built-in for show. They make the user feel safe, but do not go far enough to change the classification of the laser. Even the popular top selling home laser, Glowforge Pro, is a Class 4 laser and does have some critical safety problems preventing its classification as a Class 1 laser.

What Makes a Laser Safe?

There are a few key safety features a laser should have. Lasers should be enclosed within an enclosure that makes human exposure to the laser impossible. At a minimum, the laser should incorporate interlocks to protect accidental exposure. A manufacturer should know the materials and how to ventilate off-gassing for the safety of the operator. Again, at a minimum, the manufacturer should understand the manufacturing process and incorporate the best safety measures for each application.

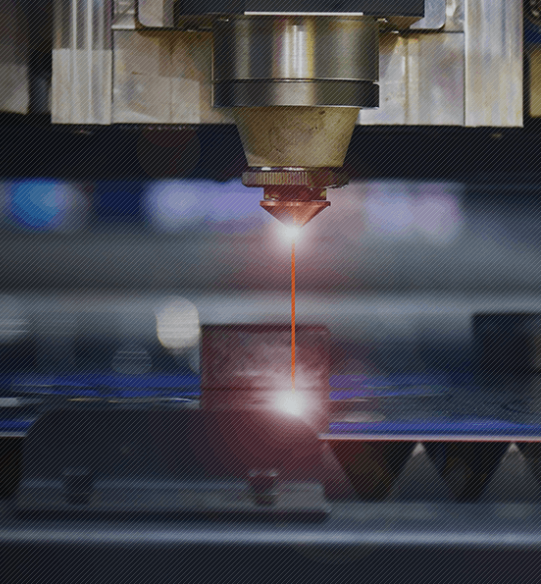

Industrial Lasers vs Hobby Lasers

Industrial lasers serve completely different customers than hobby lasers while providing a huge difference in capabilities.

The hobby laser is for DIY customers who want to make crafts or complete small projects. The array of materials they are able to mark is limited.

Only a few materials are suited for this laser—organic materials like cardboard, wood, plastics, leather, or paper. These lasers are also used for small production runs or one-off items with limited capabilities when compared to an industrial laser. Hobby lasers are either diode lasers or a gas tube Co2 lasers.

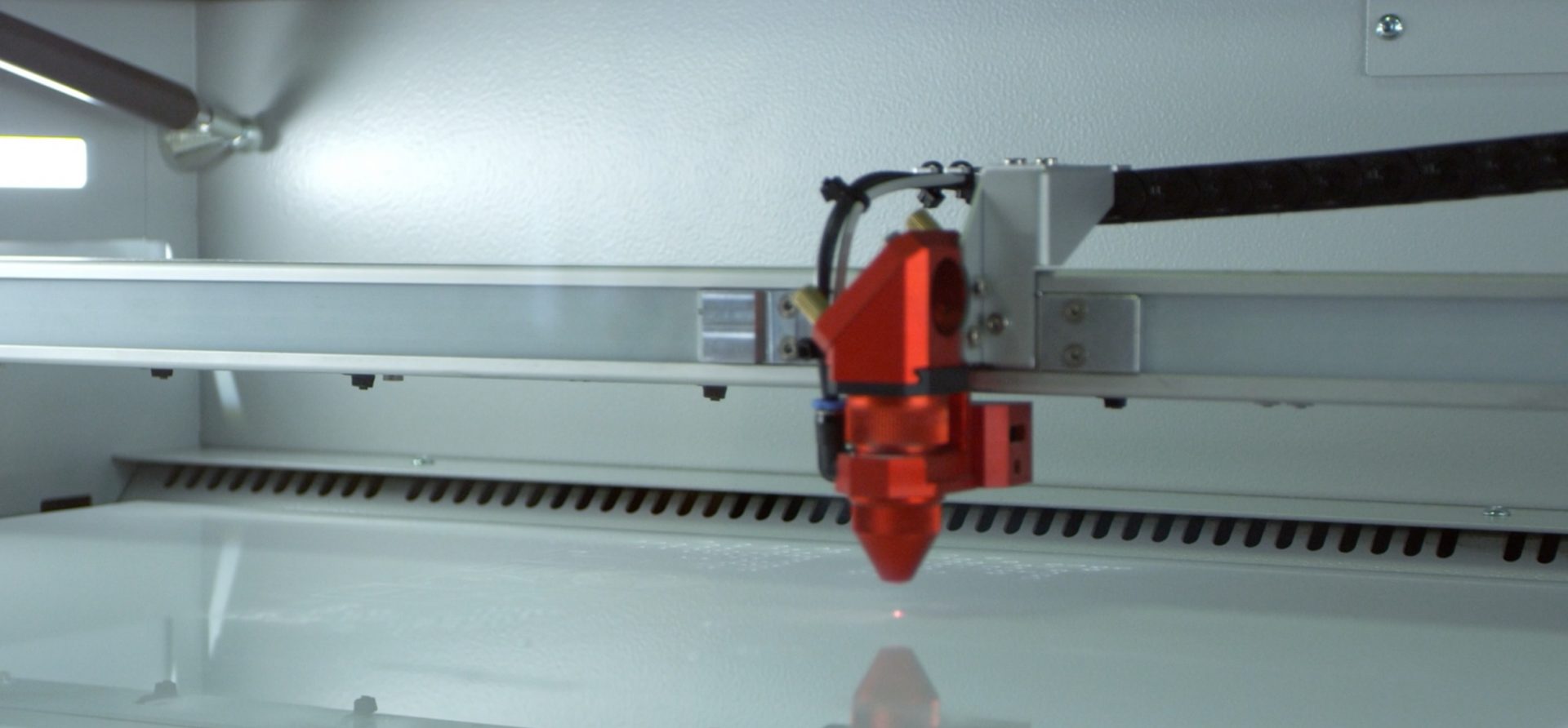

The hobby laser typically employs an X/Y gantry that moves the laser to a location, turns the laser on, then moves to generate a burned mark. By working in rows, the image or graphic builds line by line. Although effective, the laser must run slowly so the the laser can generate enough power to burn the material. The life of a hobby laser is very short (typically 2 years of normal use). Hobby lasers are good for light marking and cutting for home projects, but they are not suited for mass production or industrial use.

Telesis offers an extensive selection of industrial lasers.

Power and Speed

Hobby lasers are notorious for advertising a higher power output than they truly contain. Manufacturers advertise a simulated power that is based on th

e power going into the laser and not what is coming out of the laser. Basically, what is advertised as a 40 watt laser is actually 7 watts of power. Because of the hobby laser’s low power output, the laser must travel at speeds of 100mm per second or even slower. This means that a small 2 inch graphic can take several minutes to complete. When cutting, it may take much longer, requiring up to 30 passes to cut the material.

With an industrial laser, the power is a true measurement of what the laser is producing. Because of the power output, the laser beam will travel at very high speeds. These speeds are achieved by directing the beam with galvo mirrors. The laser beam can move at incredible speeds even above 2000mm per second.

Maintenance

For a hobby laser that utilizes a diode, the laser is a solid state laser and should not need any maintenance. However, because the laser is attached to an X/Y table, there are many moving parts. The laser moves by servo motors, it requires bearings on rail. There are also cables that wear out, belts that stretch and lose tension, and the entire area is open to the elements of the environment. Because of all these parts, the hobby laser has a high probability of failure.

An industrial laser has one moving part. Sealed inside the head are tiny mirrors that turn just slightly to direct the beam. All the components of an industrial laser are sealed inside the laser cavity and typically the laser never moves from its static position inside the class one enclosure.

—–

More Industrial Laser Advantages

Sealed Laser System

Manufacturers build everything within an industrial laser to protect the laser and optics from outside elements. They have even designed air flow to provide cooling without exposing the components to dust and debris. The only part of the laser that is exposed is the outside protective lens that can be easily cleaned by the

operator.

Minimal Moving Parts

One great quality of an industrial laser is its ability to create a beam with minimal components. It compresses light that travels through a series of lenses to focus the beam. The laser itself does not have moving parts. Directing the beam is done as it travels into a sealed galvo head. These mirrors move just a fraction of an inch and together they can reach the entire working area of the field.

Because there is so little movement in the laser, the only maintenance required is cleaning the flat field lens. Most of the time this can be done without removing the lens from the laser.

Built and assembled in the USA

If you choose a Telesis industrial laser, its markers are designed and built at their plant in Ohio. This gives Telesis a major advantage over competitors located around the world. Most hobby lasers are built and shipped from China. They are typically made with low-cost materials and finding support can be challenging.

Browse our comprehensive selection of industrial lasers.

View Industrial Laser Engravers

What about the software?

When marking with a laser, it is important to have as much control as possible over the laser parameters. Presets, or cookie cutter settings may work for simple materials and requirements, but to truly optimize the operation, you need more control over marking.

Hobby lasers use either a limited generic software or an open-source package downloaded from the internet. This type of software was designed to run all lasers and not your specific model of laser. These software packages are sometimes difficult to use and can even be a safety concern because they were not specifically tested for the laser in use. Hobby lasers are not able to be calibrated to the software, creating potentially inaccurate measurements and safety concerns.

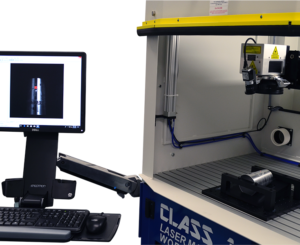

Merlin®—the proprietary visual software that runs Telesis lasers—is extremely detailed in its capabilities while also making programming very simple for the user. The depth of parameters includes setting delays, waypoints, frequency, pulse width, and other laser settings. Having this control can dramatically decrease cycle time, increase contrast, and produce higher quality. The software is paired to each laser and calibrated to precise laser control.

Service and Support

How important is it for you to have quality and responsive support?

Telesis provides complete solutions. The team at Telesis can help with every production need, from a single assembly cell to a multiple cell line. Not only do they have the ability to install the marker, service the markers, provide support and training, but they understand the needs of the customer.

Lasers Are Not Toys

Lasers are not toys. Serious injury or even death can occur with the use of a laser, especially one that has been built without any or very minimal safety measures. Hobby lasers are for the hobbyist. These lasers should never be used in true manufacturing environments.

If you would like to explore laser marking for your manufacturing process and would like a true Class 1 (the safest) laser built to your exact specification, contact Telesis. Our representatives can help you determine the best tool for your project. Telesis’ position as the industry leader for over 50 years means we’ve marked everything—the Space Shuttle, human implants, auto parts, and your favorite project.