20 Dec What Are Fiber Lasers Good For?

Fiber lasers have revolutionized many types of industries due to their unique properties and advantages over other laser technologies. They offer higher beam quality, efficiency, compactness and reliability, making them useful for a wide range of applications. You can find them in various industries, from drilling and marking to texturing and cleaning within manufacturing, automotive and aerospace applications.

Explore the diverse uses and benefits of fiber lasers.

What Are Fiber Lasers Good For?

A fiber laser is a solid-state laser that uses optical fibers as the gain medium. The optical fibers within the laser fiber are doped with rare-earth elements like erbium, ytterbium or neodymium.

Usually, gas sits at the core of a laser. A CO2 laser, for example, uses carbon dioxide. This allows for an infrared beam with wavelength bands centering on 9.4 and 10.6 micrometers. That beam level can cut a variety of materials. CO2 lasers are also useful in medical situations, such as soft-tissue surgery or dermatology.

The doped fibers within fiber lasers amplify light, and the laser beam is generated within the fiber itself. This gives it several advantages, like a higher beam quality and more efficiency, reliability and compactness.

Faber Lasers vs. Other Lasers

Compared to other lasers, fiber lasers have more stability and power efficiency.

A fiber laser produces a beam inside the core, so beam delivery doesn’t require sensitive or complex optical equipment. A normal laser usually uses an optical fiber to move the laser beam or mirrors to bounce it around. While both approaches work, both require highly precise alignment, and conventional lasers are sensitive to impact and movement. Once things misalign, a specialist has to set things right.

A fiber laser has no such sensitivity. It can handle the knocks, bumps and vibrations of any assembly line. Additionally, confining a laser beam to the doped fiber core keeps the beam compact and straight. That, in turn, allows for small and precise focusing. As a general rule in lasers, the smaller the dot created by the beam, the more effective it is for cutting.

A fiber laser is also power-efficient. It can convert nearly 100% of the input it receives into the beam, thus limiting the power converted into heat energy. This helps protect the fiber from heat damage or fracture. All of this adds up to a robust laser requiring next to no maintenance.

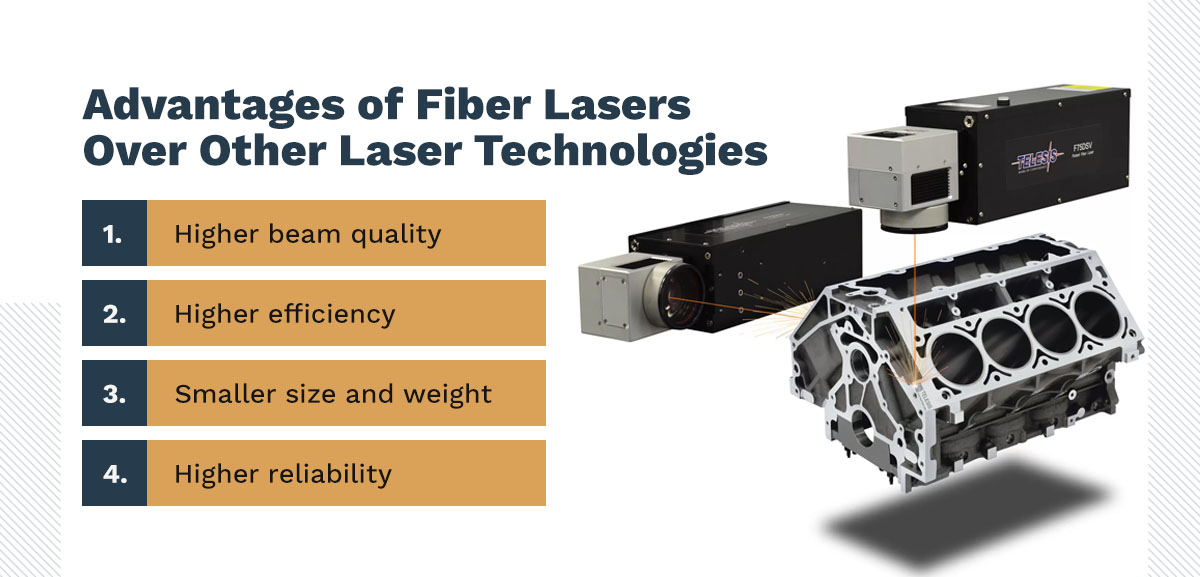

Advantages of Fiber Lasers Over Other Laser Technologies

Fiber lasers offer several advantages compared to other laser technologies, including:

- Higher beam quality: Fiber lasers usually have a higher-quality beam than other laser types, which provides more precise focusing and better performance.

- Higher efficiency: Fiber lasers are much more efficient than other lasers, consuming less power and generating less heat.

- Smaller size and weight: Fiber lasers are typically smaller and lighter than other laser types, making them easier to integrate into various systems.

- Higher reliability: Fiber lasers can typically last much longer than other lasers because they are reliable and require less upkeep.

Fiber Laser Use Cases

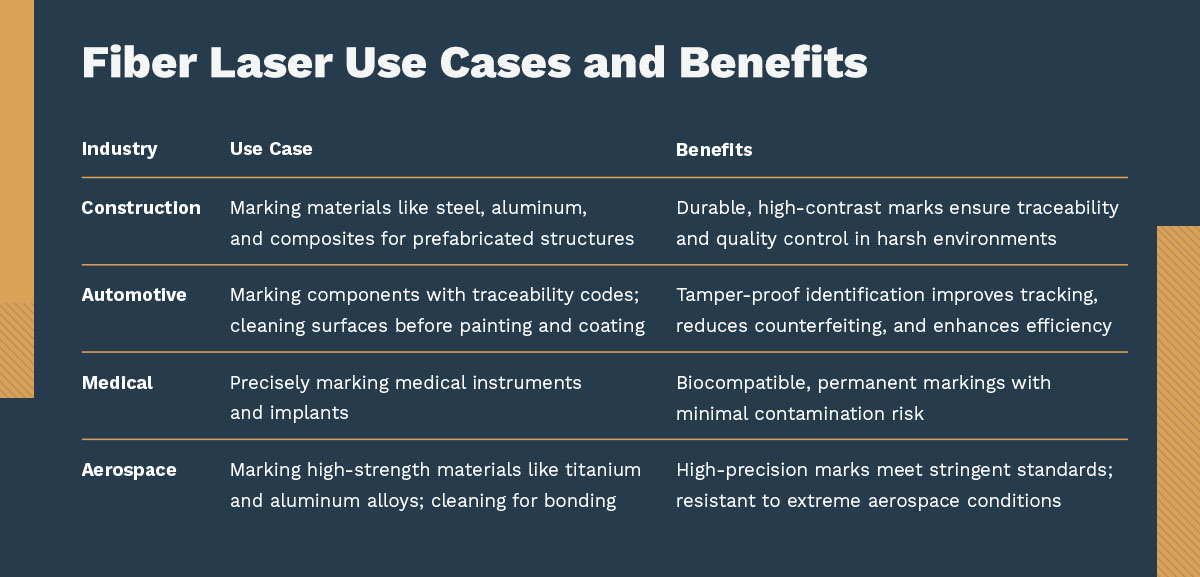

Fiber lasers can produce various wavelengths, opening them up to numerous industrial tasks — marking, cleaning, drilling and texturing, to name a few. You’ll find them in many industries, such as medicine, automotive, construction and aerospace. Here are a couple of their uses.

Construction

In construction and housing projects, fiber lasers can precisely mark materials like steel, aluminum and composites. These materials are often used in prefabricated structures and architectural elements. Laser marking provides durable identification for components, making them traceable and ensuring quality control throughout the building process.

Laser marking solutions from Telesis Technologies, Inc. provide a permanent, high-contrast mark that withstands harsh environmental conditions on the construction site. Easily integrate these systems into your workflow to reduce downtown and speed up your operations.

Automotive

Fiber lasers are used in automotive manufacturing to mark components with traceability codes. With greater speed and precision, fiber lasers can ensure a more efficient production process overall while resulting in higher-quality, reliable automotive parts. Laser cleaning is also used to prepare surfaces for painting and coating, efficiently removing rust, oxide and debris from metal surfaces.

With permanent, tamper-proof markings, you can make sure all parts are tracked throughout the supply chain, avoiding counterfeiting.

Medical

Medical device manufacturers rely on fiber lasers to precisely mark medical instruments and implants. Laser marking gives a permanent, biocompatible identification. Plus, the non-contact nature of laser processing minimizes the risk of contamination, which is crucial in medical applications.

Laser marking systems from Telesis Technologies, Inc. meet the stringent requirements of the medical device industry. Our certifications ensure that our equipment is safe and reliable for use in medical manufacturing environments.

Aerospace

Fiber lasers are used in aerospace and defense to mark components made of high-strength materials like titanium and aluminum alloys. Their precision and reliability are crucial for meeting strict standards in this field. Laser cleaning is also used to remove coatings and prepare surfaces for bonding.

Telesis Technologies, Inc. laser marking solutions provide the aerospace and defense industries with a reliable way to mark critical components with unique identifiers. Our systems are designed to withstand the harsh conditions of aerospace manufacturing, providing durable and long-lasting marks that meet industry standards.

Telesis Technologies, Inc. and the Fiber Laser

Fiber lasers have a long history. Elias Snitzer first invented them in 1963. However, the first commercial models didn’t appear on the market until the late 1980s. And Telesis Technologies, Inc.was there.

Our first model was the Ytterbium Fiber Laser. It used an approach that had gained acceptance in communications, but we recognized it could be adapted for use in marking materials. It was an earth-shattering development. This new laser marking style was the most advanced technology of its era.

We then developed the Vanadate laser system. This system uses a crystal made of vanadate (a compound of the chemical element Vanadium) with fiber-coupled diodes. The Vanadate Laser produces a high-quality beam, creating extraordinarily fine lines on a remarkably wide range of materials.

Today’s Models

Today, Telesis Technologies, Inc. manufactures and sells several varieties of ytterbium Q-switched fiber lasers for product marking. Our powerhouse models are those in the Fiber Series. These lasers have average power levels of 10-100 watts. They use a metal-sheathed fiber-optic cable to deliver a high-power beam.

Recently, we released an entirely new product line aimed at reducing costs while boosting speed throughput for manufacturing customers. The idea behind the Dual-Head Pulsed Fiber Laser Marking System is simple — let one person using just one personal computer operate multiple lasers simultaneously.

Despite its simplicity, the Dual-Head system maintains the beam quality of Telesis Technologies, Inc. fiber lasers. It is entirely air-cooled and powered by a single-phase power outlet. Most importantly, the Dual-Head system allows for an easy transition from more traditional numeric code printing to state-of-the-art 2D Matrix printing that can encode large amounts of traceability data.

Major manufacturers are seeing the benefit. The Dual Head System has been deployed and tested by leading manufacturers, such as Harley-Davidson® Motorcycles and Nissan® Motor Co. Ltd.

Next-Generation Fiber Lasers

In the rapidly changing world of fiber laser technology, no company can rest on its laurels — not even a company like Telesis Technologies, Inc. Our latest breakthrough has only recently entered production — the 100-Watt Fiber Laser system.

The engineering community has long been aware of 100-watt fiber lasers’ extraordinary power. However, individuals in the C-suite know laser systems with that power level have been too pricey for all but a few. That’s why we tasked our world-class team of scientists and engineers with creating an affordable version of such a system, and, remarkably, they have done so.

The speed and depth make the 100-Watt laser perfect for applications like creating vehicle identification number (VIN) marks in the automotive industry or part identifiers for avionics. Our engineers know that fiber laser machines’ robust nature and precise beams indicate a future of faster, less expensive marking devices.

Why Choose Telesis Technologies, Inc.?

If you’re looking to reap the benefits of fiber laser technology, choose Telesis Technologies, Inc. as your provider. Offering a large variety of permanent marking and traceability solutions, we’re ready to deliver a fiber laser marking system that speaks to your needs.

With the highly versatile and adaptable Telesis Fiber Series Laser Marking System, you can enjoy:

- Outstanding beam technology.

- Incredible performance.

- Durable construction.

- Minimal maintenance.

- Unmatched stability.

This solution comes in a compact, modular package, making it simple to integrate into your operations. The Telesis Fiber Series Laser Marking System is ideal for plastic and metal processing applications, offering direct, efficient and precise part marking. It also doesn’t require water cooling.

Contact Telesis Technologies, Inc. for Fiber Laser Marking Systems

Whether you work in automotive, aerospace, food and beverage, medical device manufacturing or another industry requiring laser marking, Telesis Technologies, Inc. is a fiber laser marking machine supplier you can trust. To learn more about upgrading your product marking applications with our innovative fiber laser technology, talk to one of our experts today.