17 Dec Inkjet Printer and Laser Marker — Which Is Right for Your Application?

Businesses across industries rely on commercial printers for everything from in-house newsletters to product identification and branding. Efficiency is a requirement when printing any document or on any substrate. As a result, there are a few types of printers for businesses to choose from.

Two of the most common types of commercial printers are the inkjet printer and laser marker. Each printer offers situational advantages, so choosing the ideal unit for your business is essential. Understanding the differences between inkjet printers and laser markers will help you decide which is best for your company.

What Is an Inkjet Printer?

Inkjet printers mark documents using liquid ink of various colors. Each ink color comes in its own cartridge. Inkjet colors include black, magenta, yellow and cyan. A small nozzle inside the printer emits the ink in color proportions that produce the desired shade. An inkjet printer can output up to 20 pages per minute, depending on the model.

The inkjet style offers various advantages in commercial printing applications. Inkjet printers are precise and provide a wide range of colors, enabling them to output detailed, colorful designs. Inkjet printers also print on surfaces such as paper, fabric, CDs and more.

Many commercial offices choose inkjet printers because they are easy to use and affordable. Standard inkjet printers come with a user-friendly interface with simple, effective controls. The cost of purchasing and installing an inkjet printer is lower than other options, although ink cartridge prices are often high.

What Is a Laser Marker?

A laser marker is a device that uses laser light to produce a chemical reaction on a material’s surface. The heat from the laser combines with a substance such as a toner powder or gas. The ensuing chemical reaction alters the surface’s appearance, creating the intended design. Consequently, a laser marker can print colored designs with high precision and accuracy.

The most common reason that laser markers are popular is the permanence of the marking. Relying on a chemical reaction rather than ink allows laser markers to imprint permanent designs onto hard surfaces like glass, metal, wood and plastic in addition to standard materials like paper. The design resists fading longer than ink.

Laser markers are also fast. Businesses can use laser marking machines to print 15-100 pages per minute.

When to Use an Inkjet Printer

The versatility, precision and affordability that inkjet printers offer make them popular in many office spaces and art studios.

Inkjet printers are ideal when printing colorful, high-resolution marketing documents and photos onto paper. It is also possible to use specialty ink optimized for printing onto textiles or packaging materials.

The comparatively low printing speeds that inkjet printers offer are acceptable for most small- to medium-scale printing applications.

When to Use a Laser Marker

Laser markers are fast and powerful, and their rapid printing speeds make them the ideal choice for large-scale printing applications. They are also ideal for printing onto hard surfaces.

The most applicable advantage that laser markers offer is their permanence. Permanence establishes them as common tools when printing onto packaging materials and products.

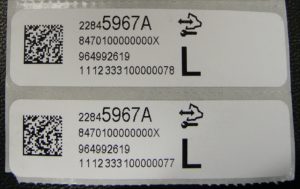

Companies will use laser markers to imprint tracking information or bar codes onto products and packaging materials. The chemical reaction produces a strong design to maintain important markings during rugged travel.

Which Printer Is Right for Your Business?

Inkjet printers and laser markers are unique in their functionality and utility. An inkjet printer is the best choice for offices, artist studios and textile production facilities with small-scale output needs requiring fine precision and vibrant coloration. Laser markers and their powerful chemical reactions are best for printing permanent designs like bar codes onto packaging materials and products with hard surfaces.

Contact Telesis Technologies, Inc.

Telesis Technologies offers powerful laser marking systems for industrial applications. Please contact us online for more on our printing solutions.

Discuss your part marking needs with an expert today // Download the Telesis Product Guide