25 Mar Do You Need a Laser Safety Enclosure?

Laser enclosures are integral to laser safety, serving as a protective barrier between the beam and operators. They can shield you from the hazards of laser exposure, like permanent eye damage, skin burns and fire hazards, while also enhancing the efficiency and longevity of your machine. If you are a business owner, supplier or technician in the manufacturing sector, read on to learn more about laser enclosures, their importance and how to integrate them for a safer, effective workflow.

Are Laser Markers Safe?

Manufacturers can build and design lasers to be safe, yet not all have the safety features they need.

A laser beam by itself would have a classification created by evaluating its power, wavelength and other factors that can harm the user. Class 4 lasers are the most hazardous lasers because they can cause permanent damage to the eyes or burn the skin. These lasers would be regulated to follow specific guidelines to prevent an accident.

Most marking lasers alone would be classified as a Class 4 laser. Some manufacturers will place their lasers in an enclosure to protect the operator but not all enclosed lasers have the same safety controls. If this enclosure has been designed correctly, the laser can have its classification lowered.

The Importance of Laser Enclosures

Enclosures enhance the safety of laser operations, offering a protective barrier against accidental exposure to laser radiation, which can lead to serious eye and skin injuries for operators. A well-designed enclosure also protects the laser’s sensitive components from environmental contaminants, enhancing its longevity and operational stability. Not to mention, many industries, including manufacturing and industrial sectors, are subject to strict regulations regarding worker safety and equipment standards like laser safety enclosure requirements.

How Do You Make Your Laser Safe?

Because of the hazards from laser exposure, some manufacturers will develop a laser enclosure to protect the operator from the laser beam, but not all safety measures are the same. The enclosures can be built in a way that classifies the laser as a Class 1 laser. Class 1 lasers are very safe but there is a higher safety that can be achieved through the Center for Devices and Radiological Health (CDRH) classification — the safest classification with the highest safety measures beyond just enclosing the laser.

With this classification, safety issues cannot arise unless the safety measures are bypassed or defeated. Laser safety enclosure features that contribute to achieving this classification include:

- Special glass for visibility and protection: With the CDRH Class 1 enclosure, your laser could have a window with glass specifically designed to block the wavelength of the laser beam. This glass allows the operator to see the marking of the laser without the potential for damage to the eyes. The glass should be certified for the wavelength and optical density of the laser.

- Interlock systems: Interlocks are designed to block the beam if a door is opened or if access is needed to the area where the beam can fire. The interlocks are connected to a shutter in the laser enclosure so that, in the event of a trigger, the shutter will drop to block the beam.

- Dual safety shutter circuits: A CDRH class laser has a dual safety shutter circuit to protect against failure. This backup circuit prevents the laser light from escaping when the door is open.

Another safety factor to look for is if the enclosure is ISO 13849 certified. Some lower-quality laser manufacturers skip critical safety features that are critical for a safe laser system.

Ventilation and Fume Management

Another safety concern of laser marking is the gases that can come from marking certain materials. During the engraving process, debris and harmful fumes can contaminate the air and cause breathing issues for operators within the workspace. In a well-built enclosure, there will be a ventilation system designed to remove the gases directly where the laser meets the part and expels fumes to a filter system that cleans the contaminants.

This is essential, especially when marking plastics, as it can improve the air quality in your laser processing area and make it more breathable for longer hours. Without these harmful fumes, operators can also concentrate better on creating top-quality designs and engravings.

Our Solutions for Laser Enclosures

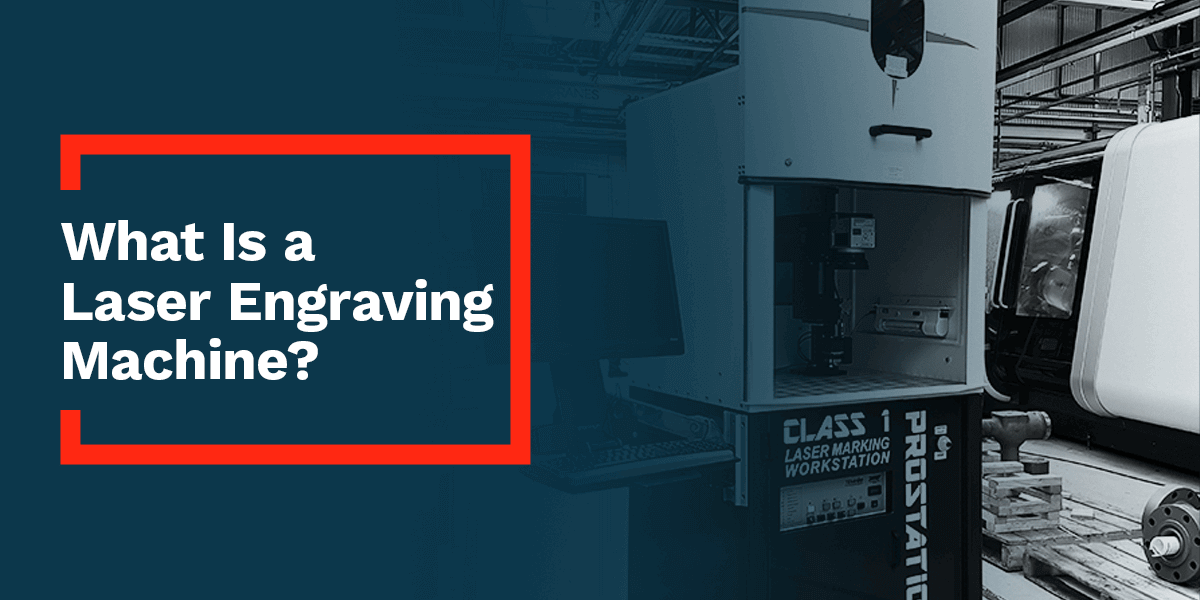

Telesis Technologies, Inc. manufactures the highest-rated CDRH Class 1 laser enclosures for its lasers. Every Telesis enclosure is ISO 13849 certified and features every safety option listed above. From entry-level enclosures perfect for job shops to the robust Telesis ProStation, Telesis enclosures can be designed as a manual system or a completely automated enclosure.

Our machines offer the following features:

- Visibility and access: Our Class 1 laser safety enclosures feature safety-rated viewing windows, doors, and access points for operators to access the machine and handle materials only when safe to do so.

- Automation: Many of our enclosures have automation features, such as conveyors, to assist in high-volume production with minimal manual intervention.

- Noise reduction: Laser enclosures can also reduce noise generated by the equipment, creating a safer, more comfortable manufacturing environment.

- Control interfaces: An easy control interface allows users to access the laser and enclosure functions from a single point.

- Mobility: Our enclosures have locking castor wheels, offering greater mobility if you need to move the laser closer or set it aside, depending on your task.

Choosing the Right Laser Enclosure

When choosing a laser enclosure, you’ll want to consider your specific application and safety requirements:

- Material and durability: Choose a durable enclosure material that can absorb or reflect the laser’s wavelength and prevent transmission. Common materials include specialized plastics, metals and laser-safe glasses.

- Interlock systems: As mentioned, choose an enclosure with safety interlocks, which allow the laser to only operate when the enclosure is securely closed, preventing accidental exposure.

- Visibility and access: While enclosures should block or weaken the laser beam, they should also allow visibility and access for maintenance and adjustments. Choose an enclosure with laser-safe viewing windows and doors that filter harmful wavelengths while providing visual access.

- Ventilation and cooling: High-powered users generate significant heat, making it crucial that the enclosure has efficient ventilation and cooling to prevent the laser and its components from overheating.

- Compliance with Standards: Your laser enclosure must also comply with certain requirements and international safety standards, such as the American National Standards Institute (ANSI) Z136 on the safe use of lasers.

Additionally, consider operational requirements when implementing an effective laser enclosure for your needs, such as ease of use, access to controls, laser wavelength and power and adequate space in your work area.

Find the Right Laser Enclosure for Your Needs With Telesis Technologies, Inc.

Laser safety enclosures are integral to laser safety, protecting operators and the equipment from potential hazards. By meeting safety standards and considering your application and specific needs, you can create a safe, effective laser workspace. Telesis Technologies, Inc. offers laser enclosures designed with top safety and efficiency features in mind.

These devices provide a safe environment for laser use while offering greater stability to the machine, enabling a precise, high-quality finish. Not sure which enclosure is right for you? Talk with one of our experts today.