23 Jul What Is the Difference Between Scribe Marking and Dot Peen Marking?

Scribe and dot peen marking are part-marking methods that support traceability, compliance and operational efficiency. However, their capabilities differ based on industrial applications. Understanding the distinction between the two methods can help you choose a solution that aligns with your production requirements and goals.

Learn about the difference between scribe marking and dot peen marking and what to consider when selecting a machine.

What Is Scribe Marking?

Scribe marking is a direct part-marking method that uses a carbide or diamond-tipped stylus to inscribe continuous lines into the surface of a material. The stylus glides across a surface under controlled pressure, resulting in a quiet, low-vibration engraving that produces clear marks. Because the stylus creates smooth, continuous lines, the marks are legible and refined.

Scribe marking systems come with integrated configurations and are typically used in environments where visual quality and noise control are necessary. While the depth of the marking depends on the machine, most models support deep line engraving.

Scribe marking is commonly used in:

- Aerospace and defense

- Automotive

- Medical devices and surgical instruments

- Metal fabrication

- Electronics

What Is Dot Peen Marking?

Dot peen marking or pin stamping is a mechanical marking method that uses a rapidly pulsing stylus to create a series of closely spaced dots. These dots combine to form alphanumeric characters, logos or machine-readable codes.

A pneumatically or electrically operated stylus moves in two axes, striking the surface in a programmed pattern. Mark depth and dot density are adjustable, making the process repeatable and ideal for variable marking.

Dot peen systems come in benchtop units for manual or automated setups, hand-held units to eliminate the need for air and portable options for marking large, immobile parts. Some models include advanced features like programmable marking heads, automatic part sensing and compatibility with 2D code verification systems.

You’ll find dot peen used in:

- Automotive and aerospace

- Defense

- Medical devices and surgical instruments

- General manufacturing for serial numbers and 2D data matrix codes

- Energy and heavy equipment

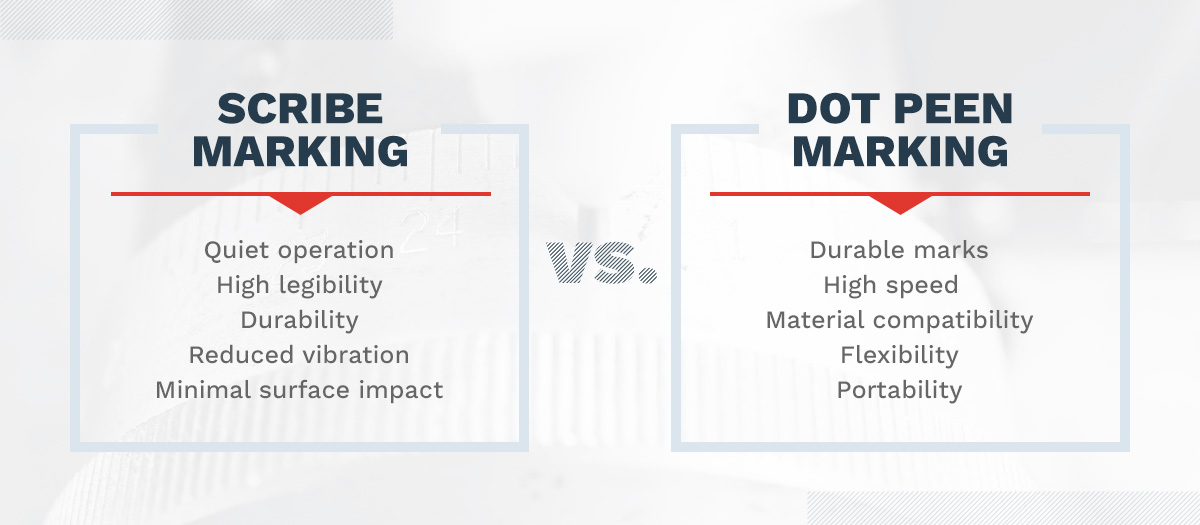

Advantages and Limitations of Scribe Marking vs. Dot Peen Marking

Scribe and dot peen marking offer proven reliability in industrial environments, but their benefits differ based on the intended use, operating conditions and characteristics. Explore the advantages and limitations of each machine below.

Advantages and Limitations of Scribe Marking

Scribe marking is valuable when surface quality, visual clarity and noise control are priorities.

Some benefits include:

- Quiet operation: The low-noise process is ideal for workstations in quieter settings.

- High legibility: Scribe marking produces fine, well-defined lines that are human-readable.

- Durability: The deep, continuous lines created by scribing are resistant to wear and corrosion.

- Reduced vibration: The gentle marking action minimizes distortion, making it suitable for thin or delicate parts.

- Minimal surface impact: Scribe marking causes less damage to a material’s surface compared to the dot peen’s impact.

The method also comes with trade-offs that may influence workflows. Limitations include:

- Slower cycle times: Some scribe machines are slow, which may impact high-throughput lines, but you can opt for models with faster marking capabilities to enhance operational efficiency.

- Tool wear: The stylus may wear faster on hardened or abrasive materials.

Advantages and Limitations of Dot Peen Marking

Dot peen marking stands out for its speed, toughness and adaptability across various materials.

Here’s where its strength lies:

- Durable marks: The method creates deep marks that withstand harsh environments, coatings and surface wear.

- High speed: Some dot peen marking machines can mark up to 5 characters per second, making them ideal for fast-paced production lines and batch marking processes.

- Material compatibility: Dot-peen machines are suitable for a wide range of materials, including hard metals and uneven surfaces.

- Flexibility: Dot peen marking can be used in manual and automated lines or integrated into existing production systems.

- Portability: Some dot peen machines are compact and easy to transport, making them easy to use in various areas with a facility.

There are a few factors to evaluate if appearance or noise levels are concerns. Considerations include:

- Noisier process: The repeated impact creates audible noise, which may require enclosures or soundproofing.

- Rougher appearance: Dot matrix marks are functional but less visually polished than scribe marks.

- Surface sensitivity: While versatile, dot peen marking may not be ideal for extremely soft or brittle surfaces.

Scribe vs. Dot Peen — Which Is Right for Your Application?

Choosing between scribe marking and dot peen marking involves comprehending how each technology fits into your workflow, priorities and production settings. Explore the factors to consider when selecting a method for your application:

- Material type and surface finish: If you’re working with hard or uneven materials, dot peen is ideal. It handles surface inconsistencies and tougher alloys with less wear on the stylus. Scribe marking offers a refined finish for smooth, flat surfaces.

- Mark quality: If appearance matters for consumer-facing parts or compliance with visual quality standards, scribe marking offers a cleaner, more refined imprint. Dot peen marks are functional and legible but have a rugged appearance because of the dot-by-dot impact pattern.

- Compliance and industry standards: Scribe and dot peen meet traceability standards, quality control and comply with industry standards and regulations. However, dot peen offers better depth for parts exposed to wear, corrosion or surface treatments.

- Production volume: Dot peen systems can handle high-speed, high-volume production environments with consistent performance. Scribe systems are typically used in lower-volume settings where precision matters more than speed.

- Workplace settings: If noise control or part sensitivity is an issue, opt for scribe marking machines for their quieter, smoother operation. Dot-peen systems generate noise because of their impact mechanism.

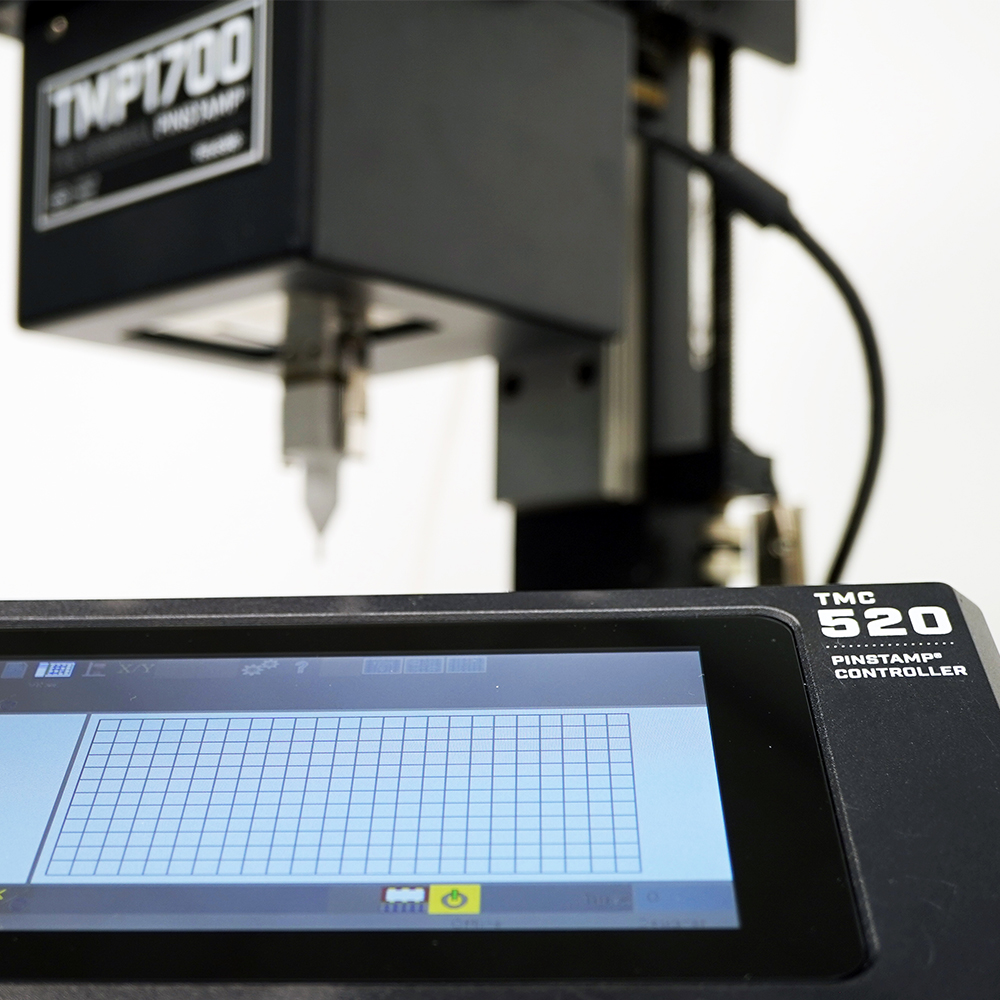

- Ease of use: Scribe and dot-peen marking machines are designed for quick deployment. Dot-peen controllers enable pattern design, data entry and efficient marking. These controllers support hundreds of stored patterns, network connectivity and easy integration. With features like floating pin for dot-peen and servo-driven scribe motors, these systems consistently follow contours, adjust stroke depth automatically and require no PC.

- Automation and integration needs: Most scribe and dot peen systems can integrate with manufacturing execution system (MES), vision software and robotics. If you’re automating a high-volume process, dot peen typically offers faster cycle times and more flexible mounting options.

Partner With Telesis Technologies, Inc. for Your Permanent Marking Needs

Telesis Technologies, Inc. helps manufacturers match the right marking method to their applications’ needs. Our scribe and dot peen systems offer durable and precise results.

With patented floating pin technology, automation options and user-friendly Merlin software, our systems are ready to scale with your production. You can count on our in-house team for service, customization and integration. Our global sales and service network ensures you’re never far from expert advice or technical assistance.

Contact your local team for assistance.