07 May What Type of Dot Peen Controller Do You Need?

Jump To:

Most dot peen markers can be controlled two ways: a controller or a computer.

The former is an efficient way to create permanent marks and introduce traceability into your facility.

You Get What You Pay For

Controllers from low end manufacturers typically use a basic controller that allows text input within a very controlled specification. These economy controllers do not offer features that are becoming increasingly important for many companies, like 2D Matrix marking capabilities, an intuitive graphic user interface, and easy programming. The basic controllers also prevent customization of the tool and have additional limitations for production line integration.

On the opposite end of the spectrum, advanced controllers open up many customizable elements that are critical to the modern manufacturing process. With this wide variety of controllers available in the marketplace, the customer must evaluate not only the current marking needs, but also the potential of adjusting and refining future marking necessities.

On an assembly line, it is likely the operator will never see the controller after it is programmed. If the controller is capable, the software program will be doing most of the work—input data is sent to the controller, the controller processes the information, then the controller drives the marker. In the most advanced controllers, the software can give a photographic visual of the part to be marked and grade the quality of a 2D Matrix Code mark, verifying its integrity.

It Depends What You Are Going to Mark and Who the Operator Is

With dot peen markers, flexibility is important. The controller should allow the programmer to make very fine adjustments to the mark for quality. Adjustments can include dot density, speed, pin standoff distance, the pin type, the amount of air pressure, and character information. Other important programming items should include 2D matrix code marking, angles, radial marking, commands, variable text, and advanced programming for automation control.

Employing the Latest Technology is Your Best Bet

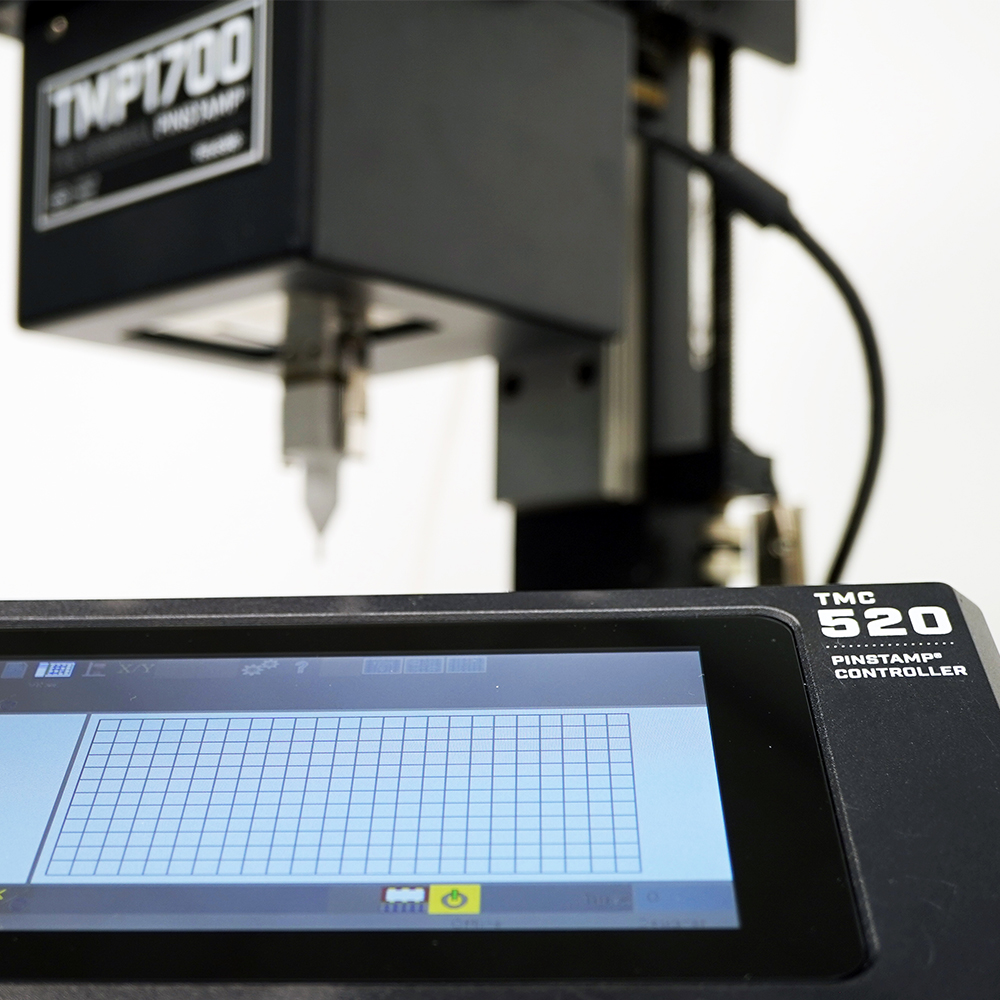

The latest controllers have full color visual touchscreens, but it is important that this type of controller will be able to withstand the harsh environments in a factory. The best quality controllers have an impact resistant screen, durable enclosure, cooling without an external fan, and easy connection for PLC and computer integration.

Telesis Technologies offers two controllers for its PINSTAMP® line of dot peen markers: the TMC470 controller, with a 8-line backlit display and the TMC520 full color touchscreen controller with graphic user interface and impact resistant screen. Merlin® (Telesis’ highly praised PC-based software) can also interface with the TMC470 if you need “what-you-see-is-what-you-get” capabilities.

The TMC520 can also be utilized with the BenchMark® line of entry level marking equipment. Both controllers are among the most advanced controllers on the market. They offer complete flexibility and control for nearly any application and can utilize a barcode scanner for input so there is no need for a keyboard to insert data (and the operator doesn’t even need to remove gloves).