02 Dec What Is a MOPA Laser?

Standard fiber laser systems often lack the precision or flexibility to keep pace with industry application requirements. Achieving consistent and legible marks supports compliance, traceability and brand integrity.

A master oscillator power amplifier (MOPA) fiber laser has adjustable pulse duration and frequency capabilities. It allows operators to tailor the marking process to specific materials and desired outcomes. The technology can create high-contrast markings and perform deep engravings with reduced heat input.

Discover what a MOPA laser is, how it works and its use cases.

Understanding MOPA Lasers

A MOPA laser is a type of fiber laser that delivers greater control over laser pulse characteristics. MOPA technology allows operators to adjust pulse duration, frequency and energy. MOPA laser systems consist of two primary components — a master oscillator and a power amplifier. Operators can tune pulse widths from a few nanoseconds to hundreds of nanoseconds by electronically controlling the oscillator.

The ability to vary the pulse provides far more versatility compared to fiber lasers, which typically have fixed parameters. Additionally, MOPA lasers differ from UV lasers in their wavelengths — MOPA lasers have a wavelength of around 1064 nanometers (nm), while UV lasers operate at shorter wavelengths, usually 355 nm. This difference affects how materials absorb the energy.

MOPA lasers are used in sectors requiring precision material processing, including:

- High contrast marking

- Color marking

- Corrosion-resistant, permanent identification

- Deep engraving

How Does a MOPA Fiber Laser Work?

A MOPA fiber laser features elements that generate a light pulse and strengthen that pulse into a usable beam. The beam generates short or long pulses that provide the desired marking in a series of steps.

1. Seed Pulse Generator

The process begins with the master oscillator, which generates the initial light pulse at the desired wavelength. The pulse is low in power, but its pulse duration, spacing and energy can be precisely defined.

2. Electronic Control of Pulse Parameters

After the seed is generated, it passes through an electronic control system. Engineers can adjust the:

- Pulse width, which allows for short or long pulses lasting from a few nanoseconds to several hundred.

- Repetition rate to determine how frequently pulses are delivered, which impacts marking speed and heat accumulation.

- Peak power to concentrate energy in each pulse, which affects whether the laser lightly alters the surface or penetrates deeper.

3. Signal Amplification

Once the pulse is generated, it passes through a fiber-based amplifier stage. The power amplifier boosts the pulse energy while preserving its carefully controlled characteristics. Amplification ensures the fine control achieved in the early stages carries through to the final output.

4. Emission of High-Power Laser Beam

After amplification, the beam is guided through the fiber-optic delivery systems to the marking head. Optical components direct and focus the beam with pinpoint accuracy. All adjustments made in the earlier stages are expressed in the final beam, allowing the operator to apply exactly the right type of interaction with the surface material.

5. Material Processing

The laser’s interaction with the material depends on the pulse duration chosen. For example:

- Short pulses concentrate energy in a brief time, producing high peak power.

- Longer pulses penetrate deeper into the material. They can create colored marks or remove more material.

What Are the Advantages of MOPA Lasers?

MOPA lasers’ advantages stem from their ability to vary pulse parameters and tailor energy delivery to the needs of each application.

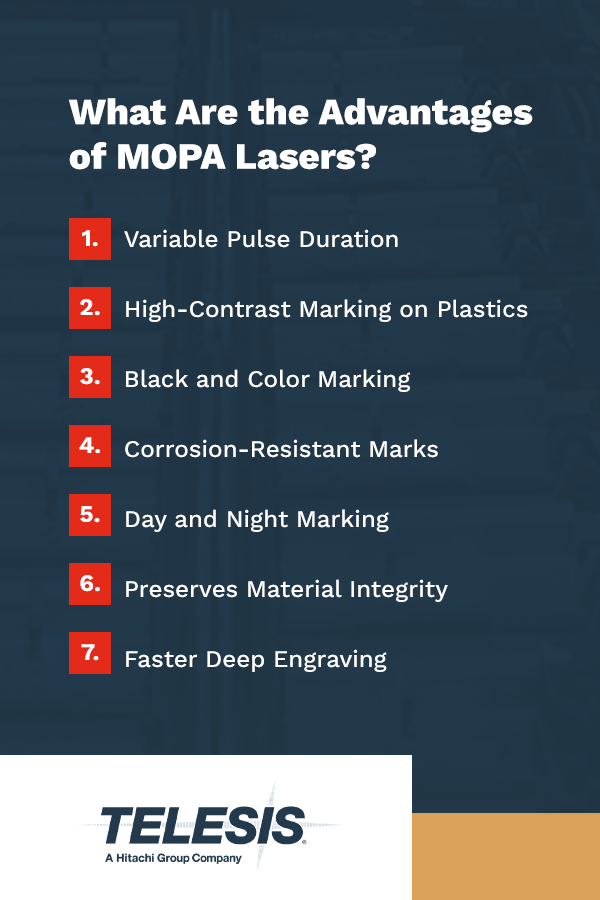

1. Variable Pulse Duration

A MOPA laser’s defining strength is its adjustable pulse duration. These systems allow operators to shift between short and long pulses. This flexibility enables the same machine to mark a delicate plastic housing with minimal thermal stress and then switch to deep engraving hardened steel components.

This adaptability reduces the need for multiple systems and provides engineers with a single platform capable of meeting diverse requirements.

2. High-Contrast Marking on Plastics

Too much heat on plastic can cause foaming, melting or surface distortion. With MOPA’s fine control over pulse width and energy, it’s possible to create sharp, high-contrast marks without damaging the substrate. For industries where plastics dominate in housings and surgical tools, this ensures durable and legible identification that holds up under regular use and sterilization processes.

3. Black and Color Marking

MOPA lasers can be tuned to adjust oxidation layers on the stainless steel or anodized aluminum surfaces, creating deep black markings or even controlled color variations.

These markings are visually striking and resistant to fading, making them ideal for branding or product differentiators.

4. Corrosion-Resistant Marks

Traceability is valuable if markings remain legible throughout a product’s lifetime. MOPA lasers create corrosion-resistant markings by minimizing micro-cracks or surface damage that could compromise protective coatings. Corrosion-resistant capabilities ensure markings remain intact when exposed to sterilization cycles, cleaning agents or harsh environmental conditions.

5. Day and Night Marking

Automotive manufacturers often require day and night markings for switches, dashboards and control panels. These markings must be clear under natural and backlit conditions. With precise control over material removal and surface contrast, MOPA lasers can create markings that perform reliably in both environments. This capability simplifies production for automotive suppliers and ensures end-users experience consistent readability and functionality.

6. Preserves Material Integrity

The shorter pulses with high peak power feature allow MOPA lasers to achieve a phenomenon referred to as cold marking. Energy is concentrated in short intervals where heat does not spread into the surrounding material. This minimizes the risk of warping, discoloration or micro-cracking, helping protect thin plastics, coated metals or electronics components.

7. Faster Deep Engraving

When longer pulses are selected, MOPA lasers can deliver consistent energy to penetrate deeper into a material with fewer passes. This flexibility makes them effective for industrial engraving tasks such as tools and heavy-duty parts. It also allows for a faster process while preserving edge quality or surface finish.

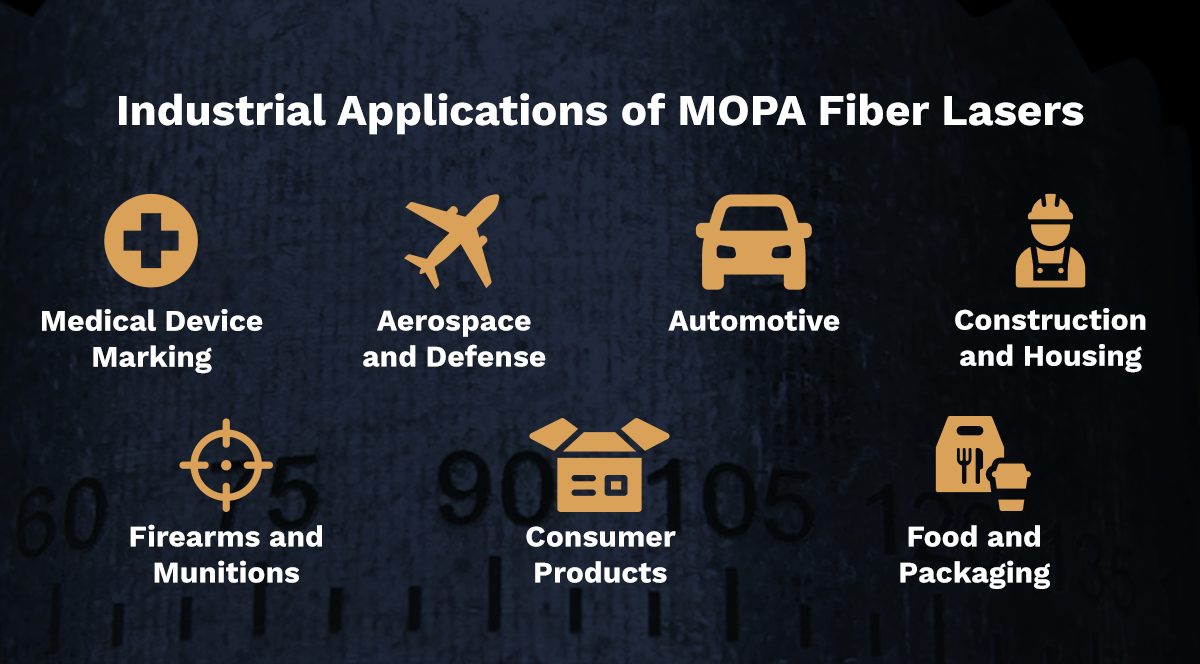

Industrial Applications of MOPA Fiber Lasers

MOPA laser systems serve different permanent marking purposes in various industries. Their adaptability reduces the need for multiple specialized tools and ensures consistent quality across a broad range of materials and regulatory requirements.

Medical Device Marking

Traceability and durability are critical in the medical sector. Surgical tools, implants and diagnostic devices require unique device identification codes that remain legible throughout the product’s lifetime. Traditional engraving methods risk compromising surface integrity, which can lead to corrosion or failure under sterilization.

MOPA lasers solve this by creating high-contrast, corrosion-resistant marks while protecting surface layers. Black markings on stainless steel surgical instruments can be achieved with minimal or no introduction of cracks or roughness that might harbor bacteria.

Aerospace and Defense

Aerospace and defense applications require markings that withstand high temperatures, vibration and corrosive environments. Serial numbers and part identifiers must remain intact over long service lives.

MOPA lasers produce permanent, corrosion-resistant marks on aerospace-grade alloys and adapt pulse parameters for different materials. This capability prevents microstructural damage and supports compliance with industry regulations and standards. The precision of MOPA technology ensures traceability without compromising performance in mission-critical components.

Automotive

The automotive industry combines high production volumes with diverse marking requirements. Vehicle identification numbers (VINs), component part numbers and user interface controls require precise marking solutions.

MOPA lasers enable deep engraving for durable VIN codes and perform subtle surface treatments for backlit buttons and switches. This dual capability allows manufacturers to streamline production, using a single laser platform to cover multiple functions.

Construction and Housing

Equipment and materials in construction and housing must often be marked for traceability, compliance and safety standards. Structural components, heavy machinery parts and identification plates require marks that withstand outdoor conditions and abrasion.

MOPA lasers provide durable, weather-resistant markings on steel, aluminum and coated metals. They minimize heat distortion, ensuring markings remain sharp on thick or treated surfaces.

Firearms and Munitions

The firearms and munitions industry relies on permanent, tamper-proof markings for regulatory compliance, serial tracking and branding. MOPA lasers deliver high-contrast, corrosion-resistant identifiers on steel, aluminum and polymer firearm components.

Their precision allows for micro-engraving of detailed logos or serial numbers while maintaining the integrity of barrels, receivers or ammunition casings.

Consumer Products

Brand identity and traceability require high-quality, aesthetically pleasing markings. Appliances, tools and electronics benefit from permanent identifiers that resist wear and enhance visual appeal.

MOPA lasers enable color marking on materials to produce logos, serials and decorative elements. Their ability to adjust pulse width reduces material damage, making them suitable for functional and branding applications.

Food and Packaging

Food and packaging industries require non-toxic, legible markings for batch codes, expiration dates and traceability identifiers. MOPA lasers’ non-contact, ink-free process eliminates chemical contamination on plastics and coated metals.

Contact Telesis Technologies, Inc. for Your Permanent Marking Needs

Telesis Technologies, Inc. provides reliable permanent marking solutions tailored to your requirements. For those seeking advanced laser capabilities with a lower upfront investment, XpressMark MOPA™ is an excellent choice. We also offer dot peen and scribe systems and many other laser marking options with Merlin software. Our patented floating pin technology ensures consistent, reliable marks on challenging surfaces. We provide environmentally friendly and compliant solutions.

Trusted by leading auto manufacturers, as well as NASA, the Department of War, and other federal agencies, Telesis is committed to excellence. We are also proud to employ veterans who contribute to making our products. Our in-house experts assist with custom laser marking solutions, integration, and provide ongoing support, always maintaining confidentiality if requested. Every system provides long-term performance, and our global sales and support teams are there to help you every step of the way.

Many of our popular dot peen markers, XpressMark, and MOPA lasers are in stock now and ready to ship for immediate delivery. Fill out a contact form to learn more.