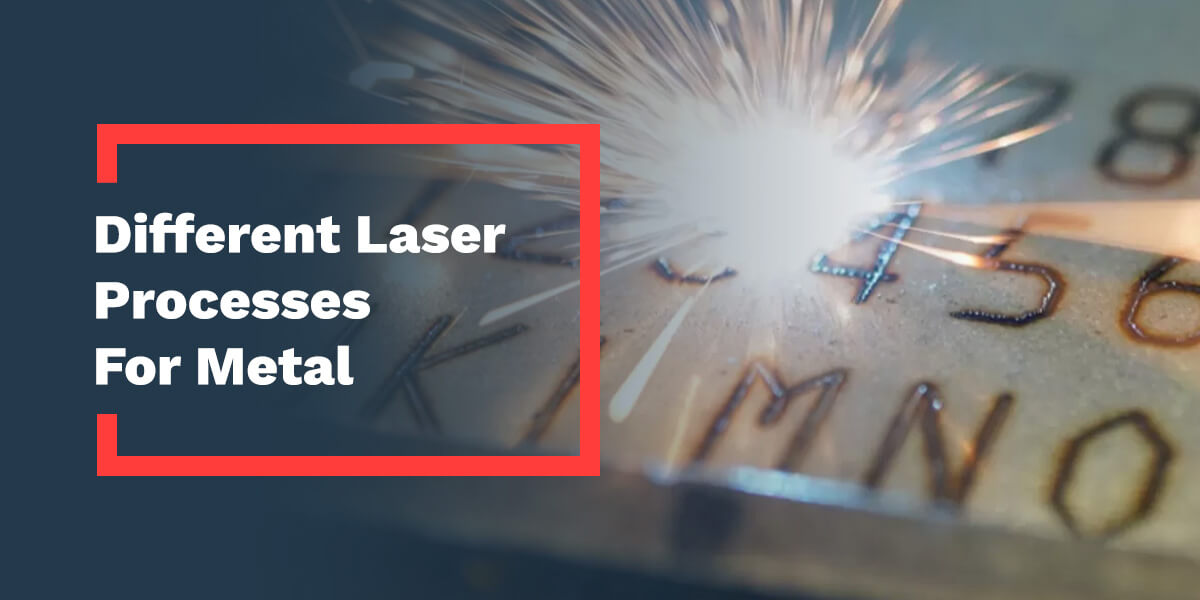

16 Aug Different Laser Processes for Metal

When marking metal, you have to consider the kind of metal you are going to mark as well as your application and production needs to find the most suitable marking process. You can use etching, engraving or annealing to mark metal items. Each process has advantages and drawbacks and is more suited for specific applications. Choosing an appropriate marking technique for your business can improve your product quality, enhance compliance and streamline your marking process, helping you gain a competitive edge in your industry.

Learn about the different processes to mark metal and find a method that best works for your application — whether you want to decorate metal items with intricate designs or add traceability markings like barcodes or serial numbers.

Laser Etching

Laser etching delivers high amounts of energy to a small surface area using a laser beam. The thermal energy from the laser heats the metal, causing its surface to melt and expand, resulting in permanent raised markings. You can use this versatile marking process for an array of metals, including steel, lead, aluminum and coated brass.

Laser etching can create fast and precise markings. This process alters the surface finish of metals, resulting in a clear visual contrast between the markings and material, offering good legibility. This process also preserves the rigidity and strength of a metal, as it is less invasive than laser engraving. You might also opt for this marking technique for stylistic reasons, as the raised marks of laser etching can add visual interest to items.

Various industries rely on etching to mark their products. Use laser etching for applications like:

- Identification and traceability features like serial numbers, QR codes and barcodes.

- Branding features like slogans and logos.

Laser Engraving

Laser engravers for metal use laser beams to remove the material’s surface. The laser beams will raise the temperature of a metal object, essentially vaporizing the material in the area where the laser beam light falls. This creates deep, heavy-duty marks that can resist harsh environments, abrasion and most surface treatments. Though slower than other processes, engraving yields highly durable results — markings will not wear out or become distorted over time. This invasive process can also create precise 3D forms that other processes can’t achieve.

You can laser-engrave on various metals, including:

- Steel

- Aluminum and anodized aluminum

- Galvanized metals

- Titanium

- Brass and copper

- Silver and gold

Hobbyists, small businesses and mass manufacturing choose this process because of its versatility and ability to engrave long-lasting markings. The automotive and jewelry industry utilizes this process, as well as the medical industry, to create legible, precise, permanent markings. This technique is used for traceability and identification of features like QR codes, serial numbers and barcodes.

Annealing or Carbon Migration

Annealing, or carbon migration, is the process of slowly heating metal with a laser beam, causing oxygen to diffuse and bond below the surface. When the metal chemically bonds with molecules below the part’s surface, it creates a dark, permanent mark.

Laser annealing is a process that doesn’t use ablation, meaning the laser does not remove materials from the surface of the metal. That’s why this marking method is often used to avoid damage to the part surface. This process allows you to achieve a wide array of yellow, blue and brown markings, but annealing only marks certain metals like titanium, steel and stainless steel. The medical industry often uses this process to mark Unique Device Identification (UDI) codes on equipment.

Which Laser Engraving Process Is Best?

While it is easy to automate both laser etching and engraving processes, etching is the most efficient as it is the fastest process that requires less laser power. However, if you need markings that offer maximum durability, it’s best to opt for laser engraving, as these markings are much deeper than etching marks.

Laser annealing is the slowest marking process as it uses low power over long periods to mark objects. While this process allows you to produce some color variations, it also helps prevent oxidation and rust, as the marking process does not create any crevices on the metal.

When choosing a marking process, consider your application. If marking speed is essential for your application, opt for etching. For durable markings, choose engraving, and if you need objects to be rust-free or operate in environments with strict health and safety regulations, go with annealing.

Advancements and Future Marking Trends

Laser marking equipment is continually advancing to enhance efficiency. These high-power machines work at increased speeds to effectively reduce marking time. Implementing advanced machine learning algorithms also aids in marking efficiency as artificial intelligence automatically sets engraving parameters. The industry is also introducing robotics to the marking process to help with part inspection, loading and unloading and part positioning.

Now, the industry also produces shorter wavelength lasers to enhance accuracy, as this equipment offers markings with better contrast and higher resolution. Lastly, advanced laser equipment allows the marking of various metals and other materials, making these machines more versatile.

As engineers and researchers keep pushing the boundaries of what is possible, laser technology continues to advance, and the industry will see more innovative applications of laser marking equipment in the future.

Utilize the Right Marking Process for Your Application

By utilizing the most suitable marking process, whether etching, engraving or annealing, for your application, you can mark your metal items efficiently. Telesis Technologies, Inc. offers a wide variety of premium marking equipment that stand up to challenges or harsh environments. As industry leaders, we offer advanced solutions. With our robotic solutions and cutting-edge software, you can streamline your marking process and gain a competitive edge in the industry.

Telesis Technologies, Inc. also deploys thoroughly trained field engineers to help production staff implement our technology for a smooth transition in production procedures. For more information about our marking equipment and software, reach out to our knowledgeable team online — we’re committed to helping you find the best solution for your marking needs.