Types of Laser Engravers for Metal

We offer a comprehensive list of laser engravers for metal, including:

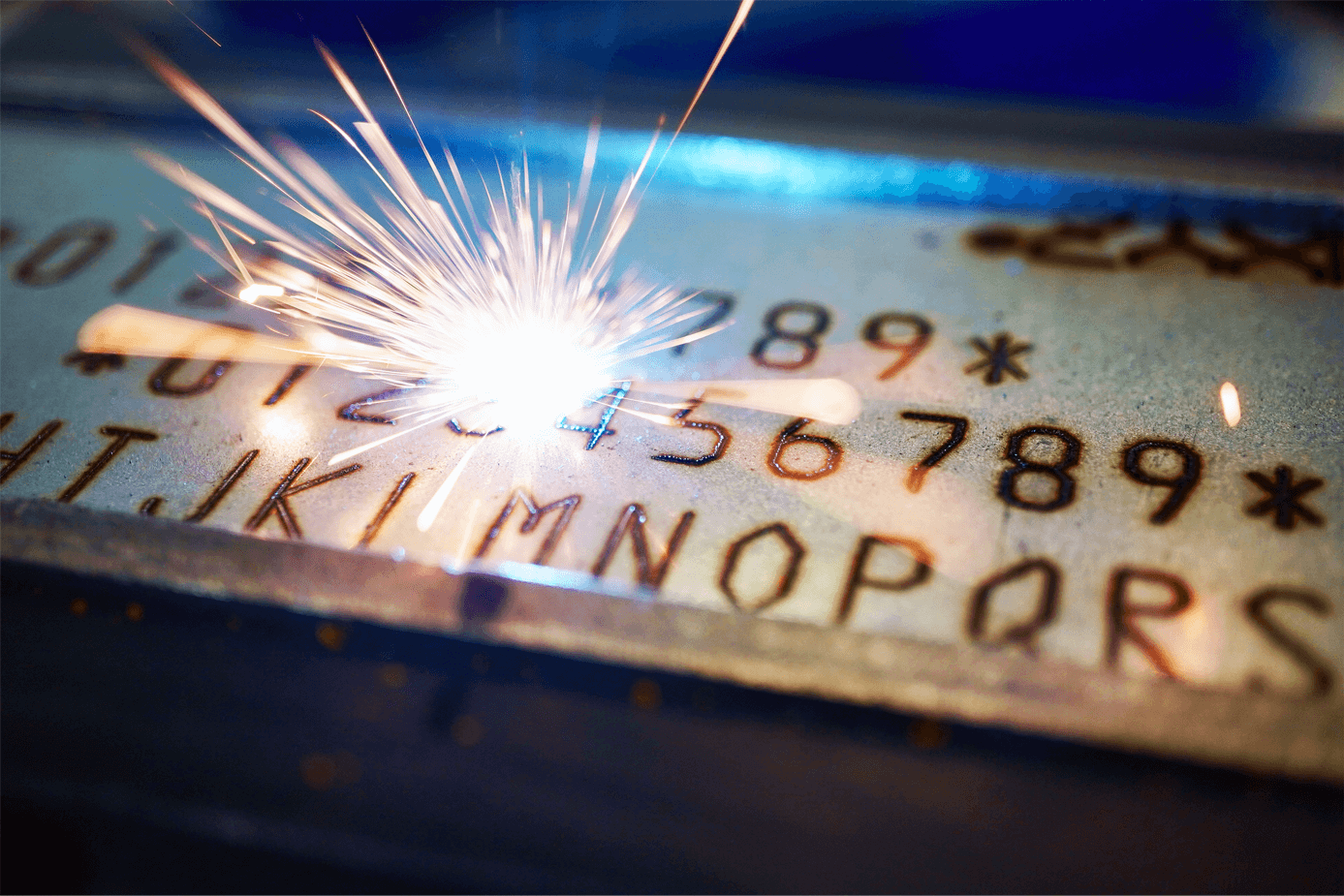

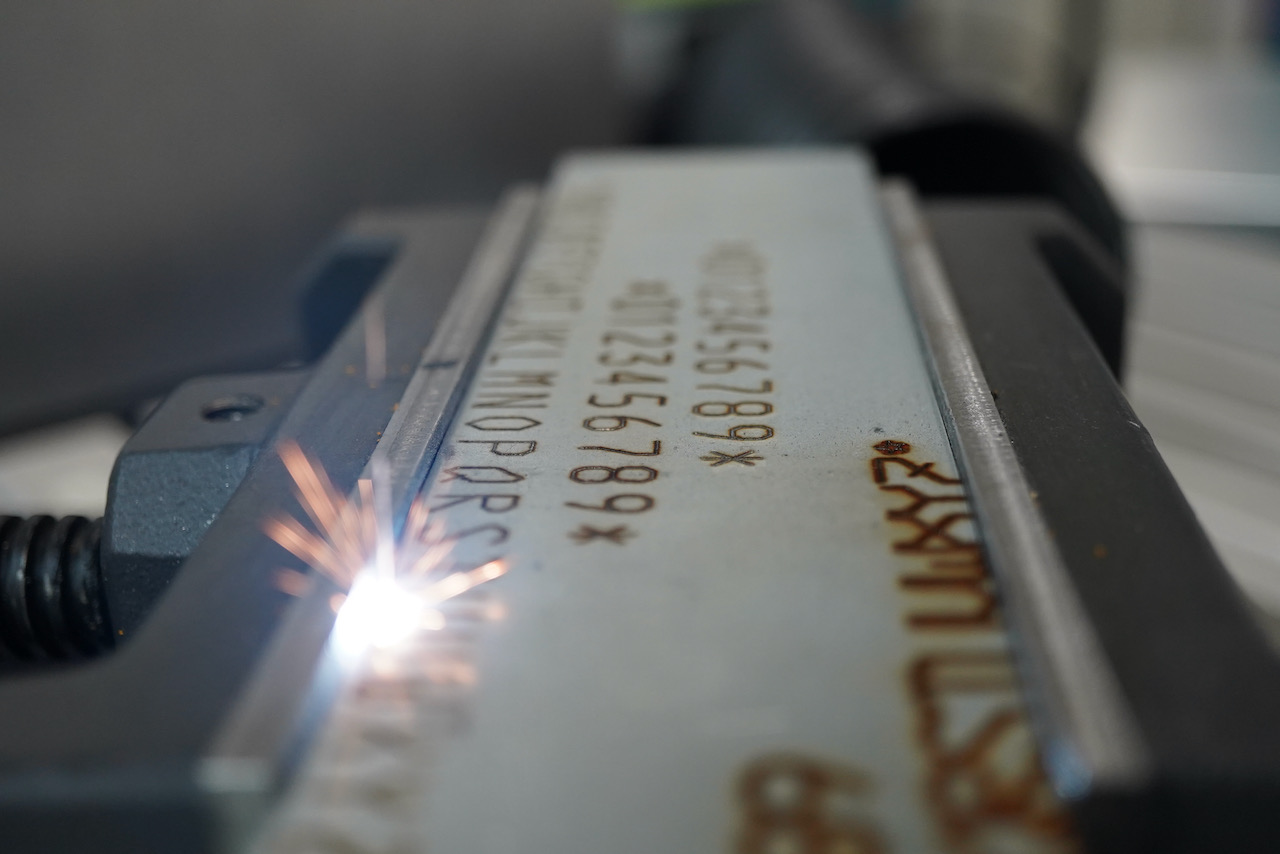

Laser engraving metal entails directing a beam of light through a lens and onto a metal surface. The process creates a permanent mark on the workpiece by removing or altering the affected material, providing a reliable way to trace products. You can laser engrave metal to create unique identifiers like logos, serial numbers, text and data matrix codes.

Selecting the right laser engraver for metal items is crucial to ensure the quality and longevity of the markings.

Contact UsLaser engraving has several advantages that can help you work faster and achieve superior outcomes on metallic workpieces. Some advantages include:

Create permanent, high-precision markings that remain clear over time.

Laser marking is a high-speed process that works well as part of a production line.

Laser engraving metal eliminates the need for consumables, making it more affordable, energy-efficient and sustainable.

You can mark metals like stainless steel, aluminum and titanium, making this process ideal for shops that take on many types of jobs.

Laser engraving metal has various applications across different sectors. Consumer products applications include text and logos on gadgets and appliances. Operators may use lasers to engrave part ID information on metallic components such as barcodes, data matrix codes, and serial numbers

Text on Metal Gadgets

Logo Engravings

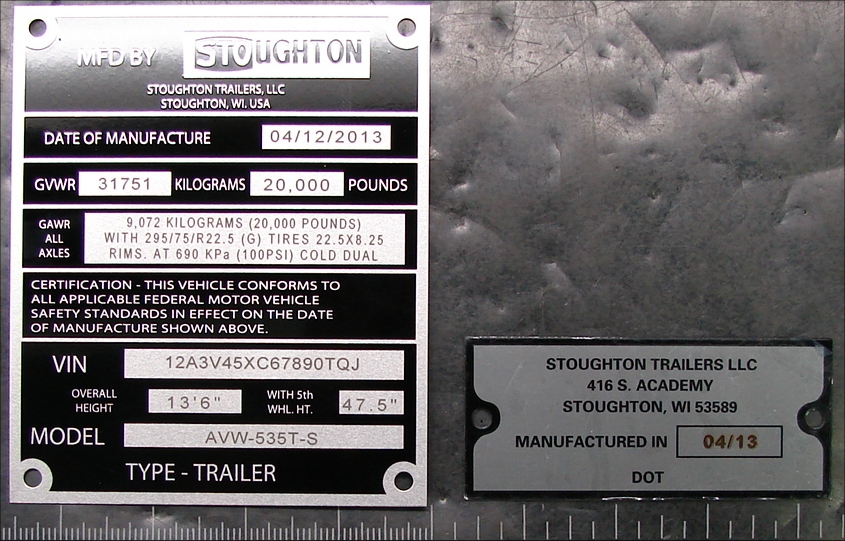

ID Plates

Data Matrix Codes

Serial Numbers

Barcodes

Expiration Information

Paint Coated Engraving on Metal

Double Line Text on Metal

Fasteners & Valve Fitting

Dogtag IDs

We offer a comprehensive list of laser engravers for metal, including:

CO2 lasers are ideal for coated metals like powder-coated and anodized aluminum.

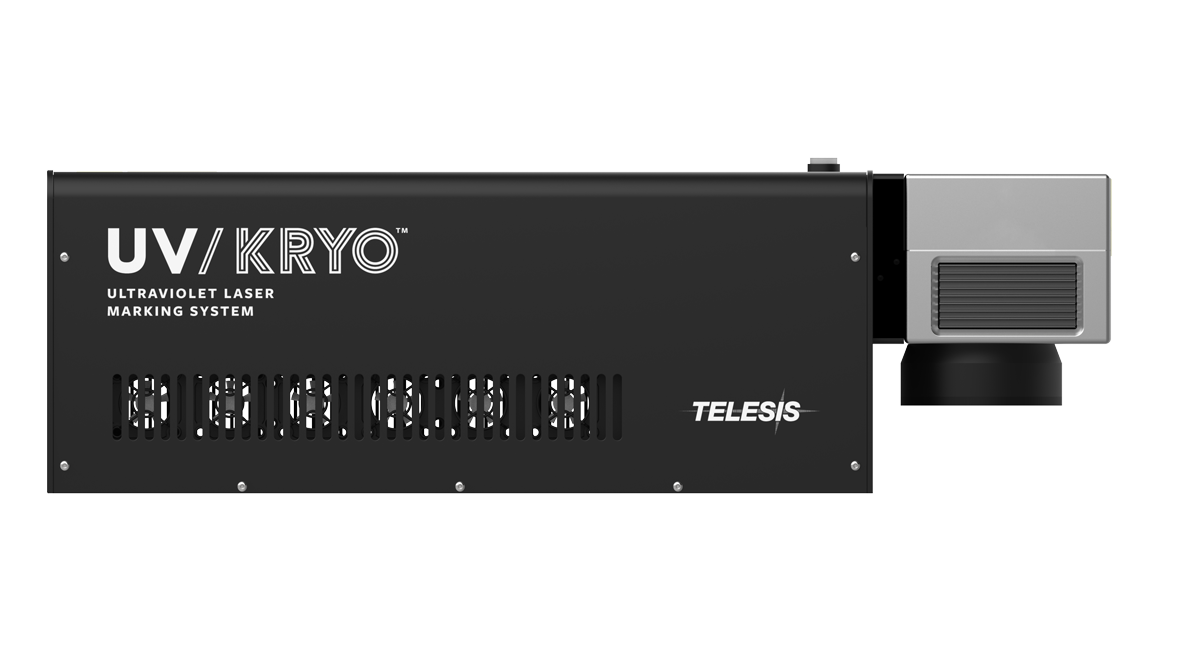

These laser markers work well for projects requiring high beam stability and ultrafine markings, making them an excellent choice for delicate substrates.

Fiber laser markers need little maintenance and no consumables. They’re ideal for high-precision markings on bare metal.

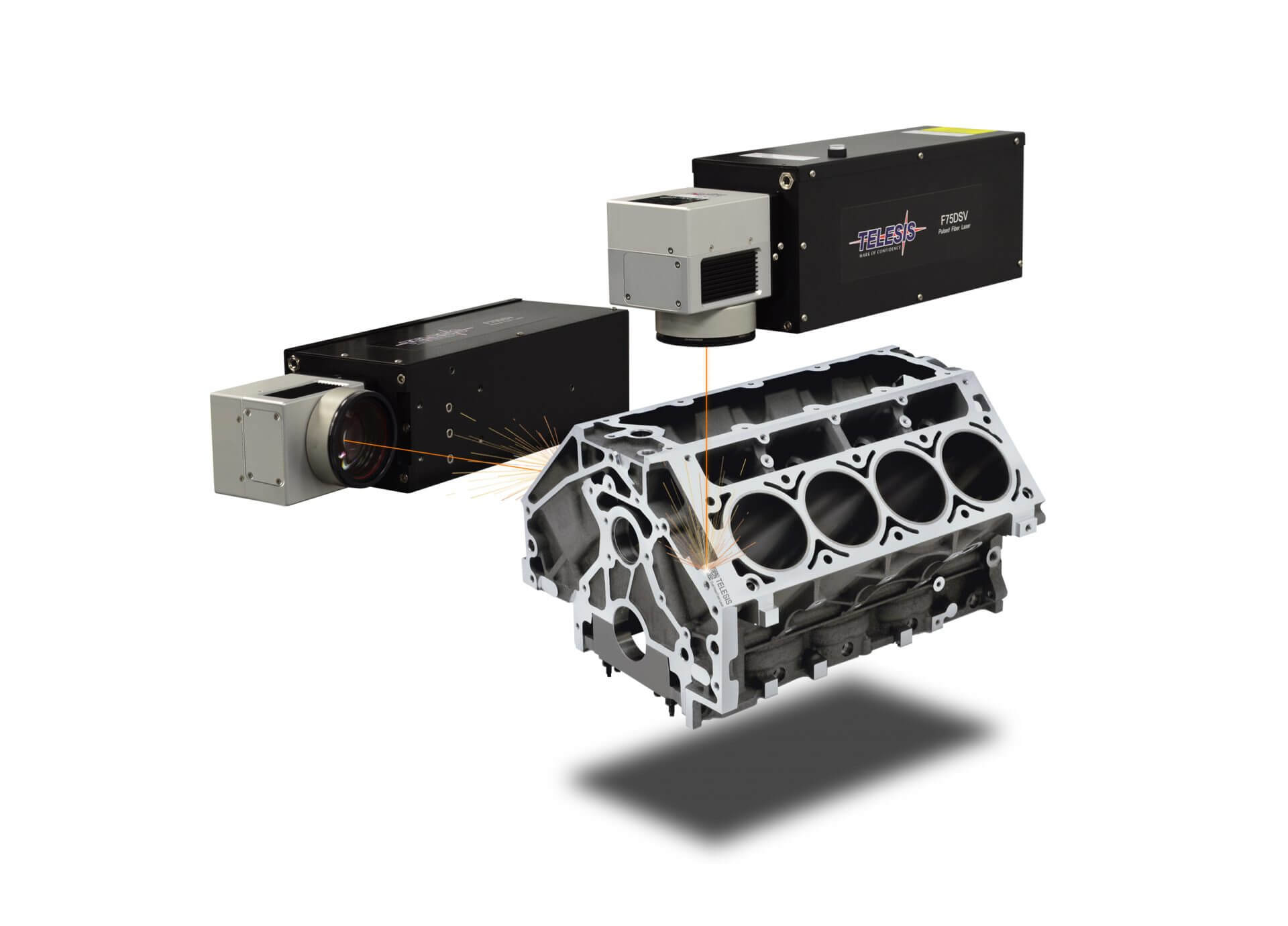

Featuring two lasers operated by one controller, dual-head lasers streamline rapid metal processing.

With exceptional beam laser quality and superior peak power, Vanadate lasers can mark heat-sensitive metals with quality results.

These lasers produce precise, high-resolution micro-markings, which are ideal for uncoated metals.

Telesis Technologies, Inc. uses cutting-edge techniques to provide rugged and practical laser marking tools that can save you time. As the pioneers of permanent engraving, we’re always striving for better. See why we’re the trusted choice for many manufacturers and other operations that rely on metal marking solutions:

Telesis has VIN systems placed over 25 years ago still operating today – the longevity of our systems are matched only by our ongoing service and support of our global corporation that is part of every marking system sold by Telesis.

Mark up to six characters per second with the TMM5100 Multi-Pin Marking System. Its lightweight, compact design, and minimal footprint are ideal for hand-held, stand-alone or completely integrated, factory automated operations.