Why Use Laser Marking in the Automotive Industry?

Traceability is the process of tracking each step of the manufacturing and distribution process as a product travels to the end consumer. Automotive vehicles contain thousands of components produced by dozens of suppliers, making traceability vital in ensuring that each part makes it exactly where it’s meant to go and is identifiable. That’s where automotive laser marking comes in.

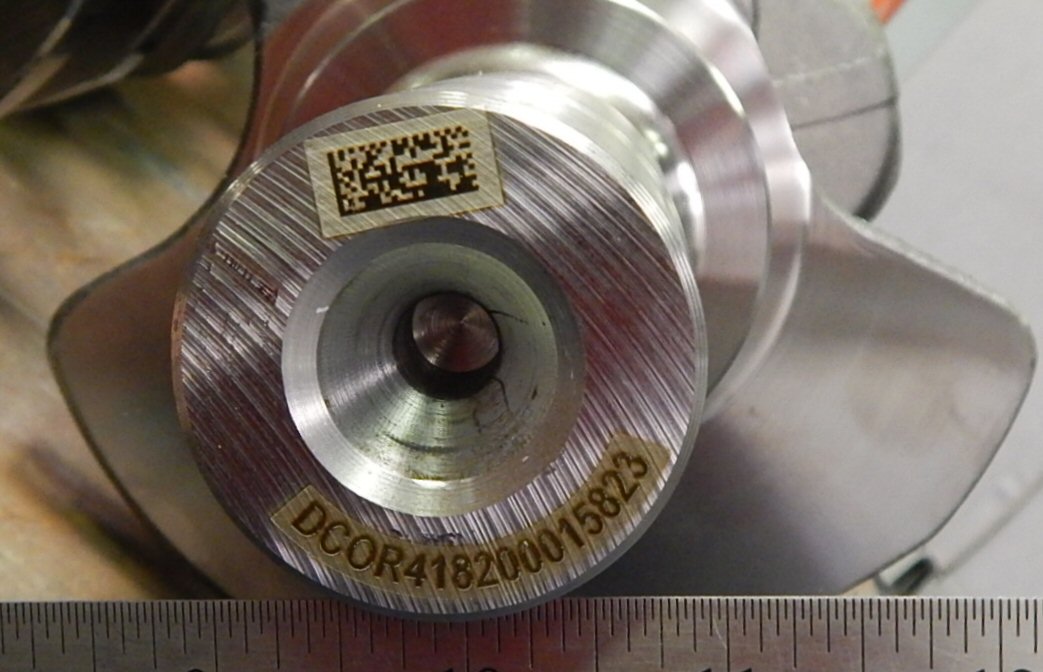

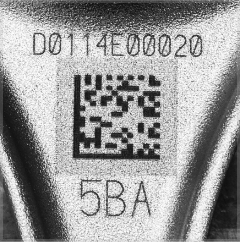

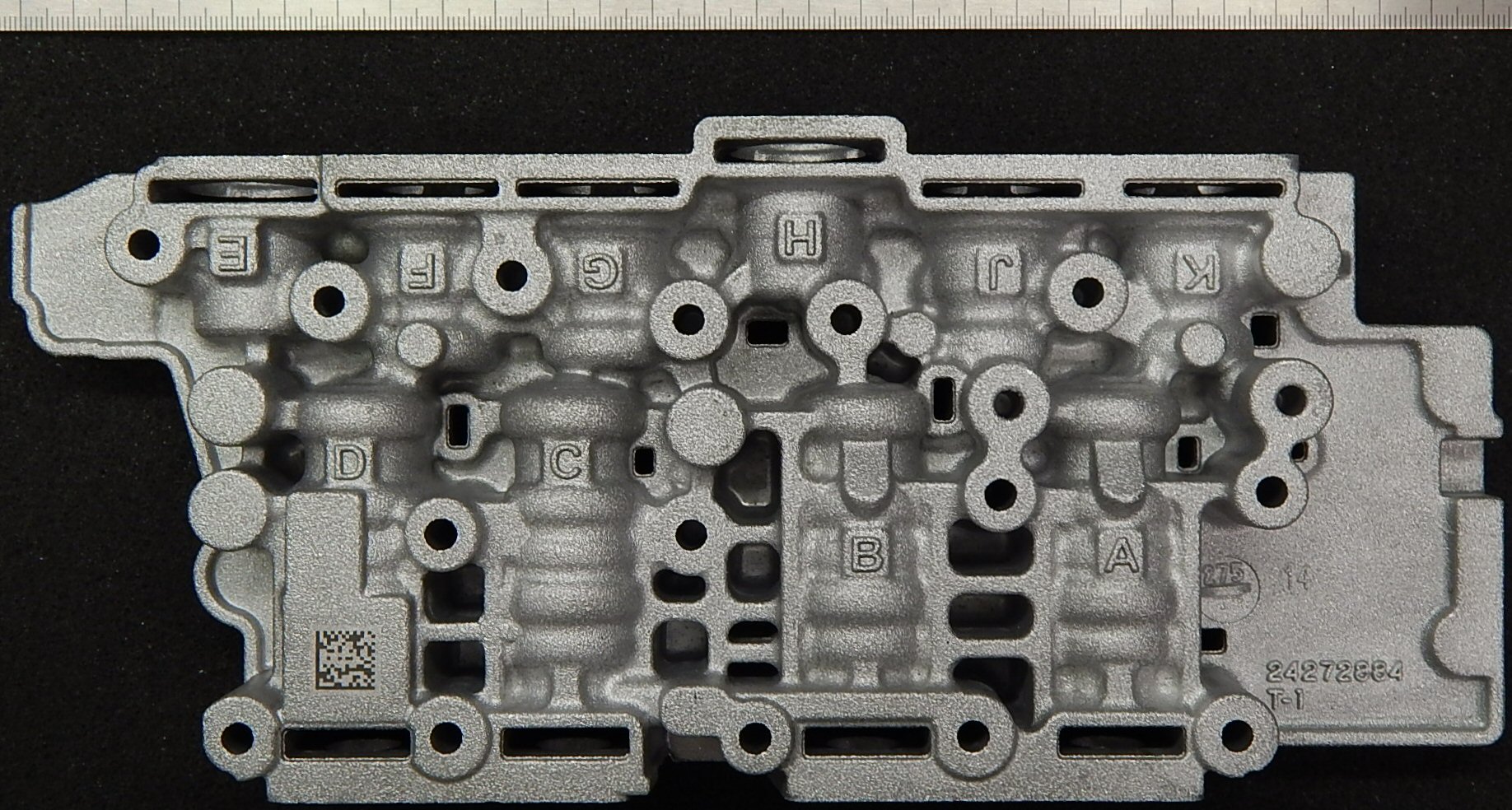

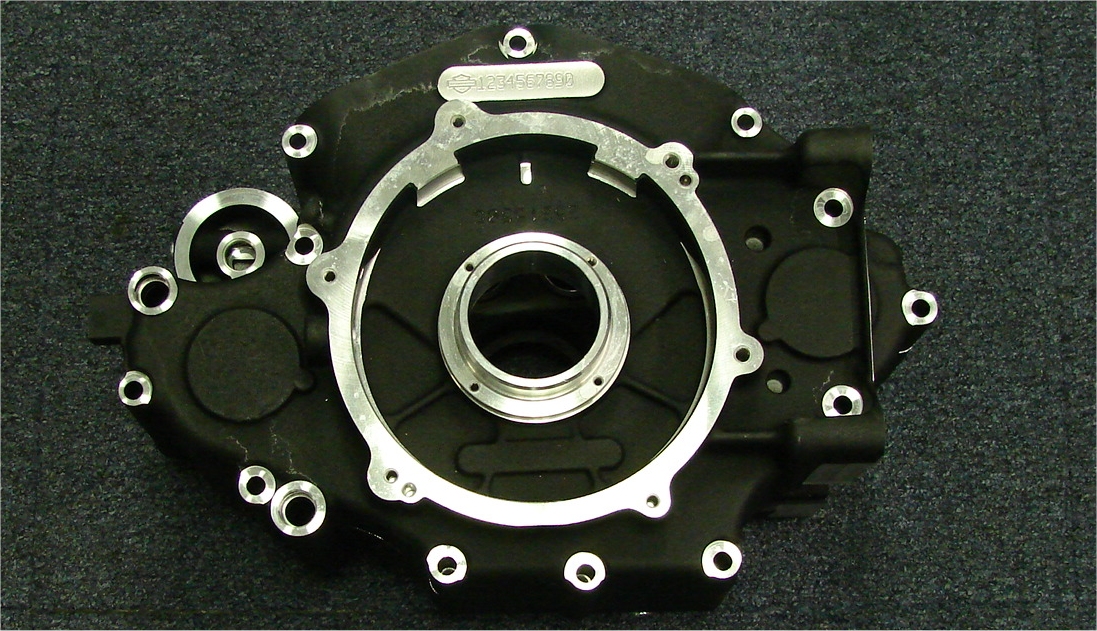

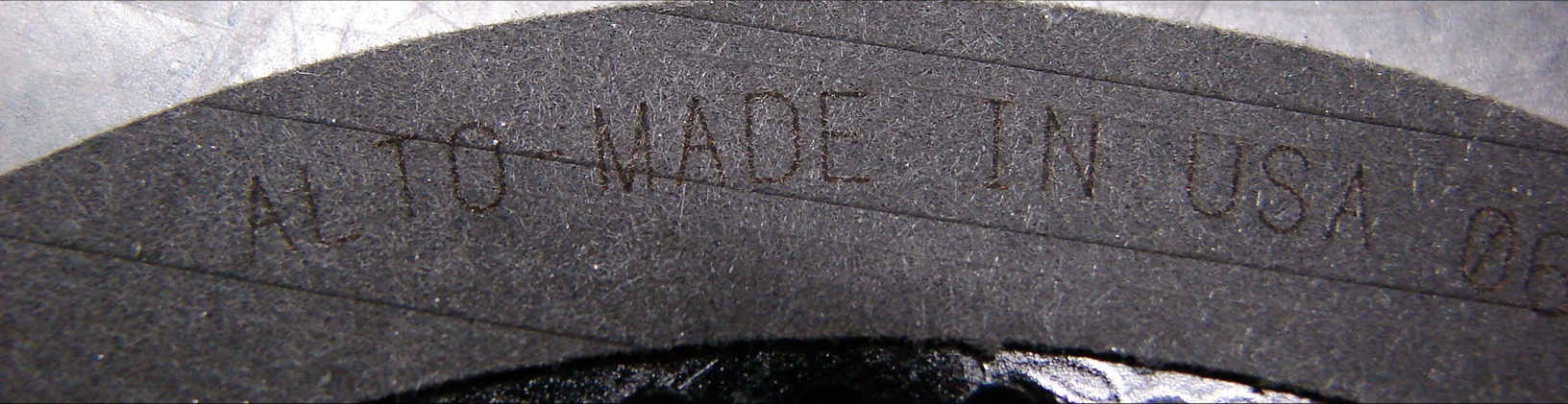

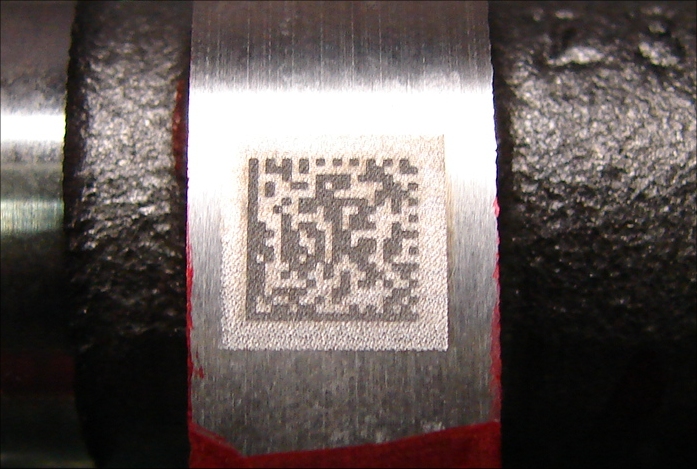

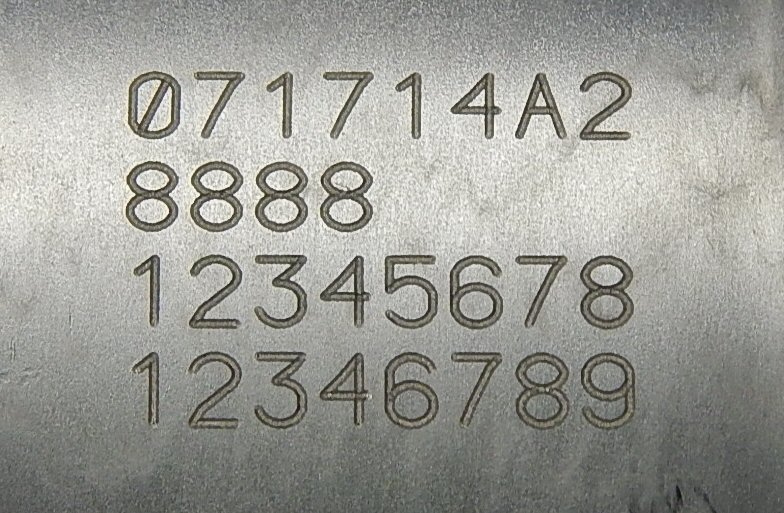

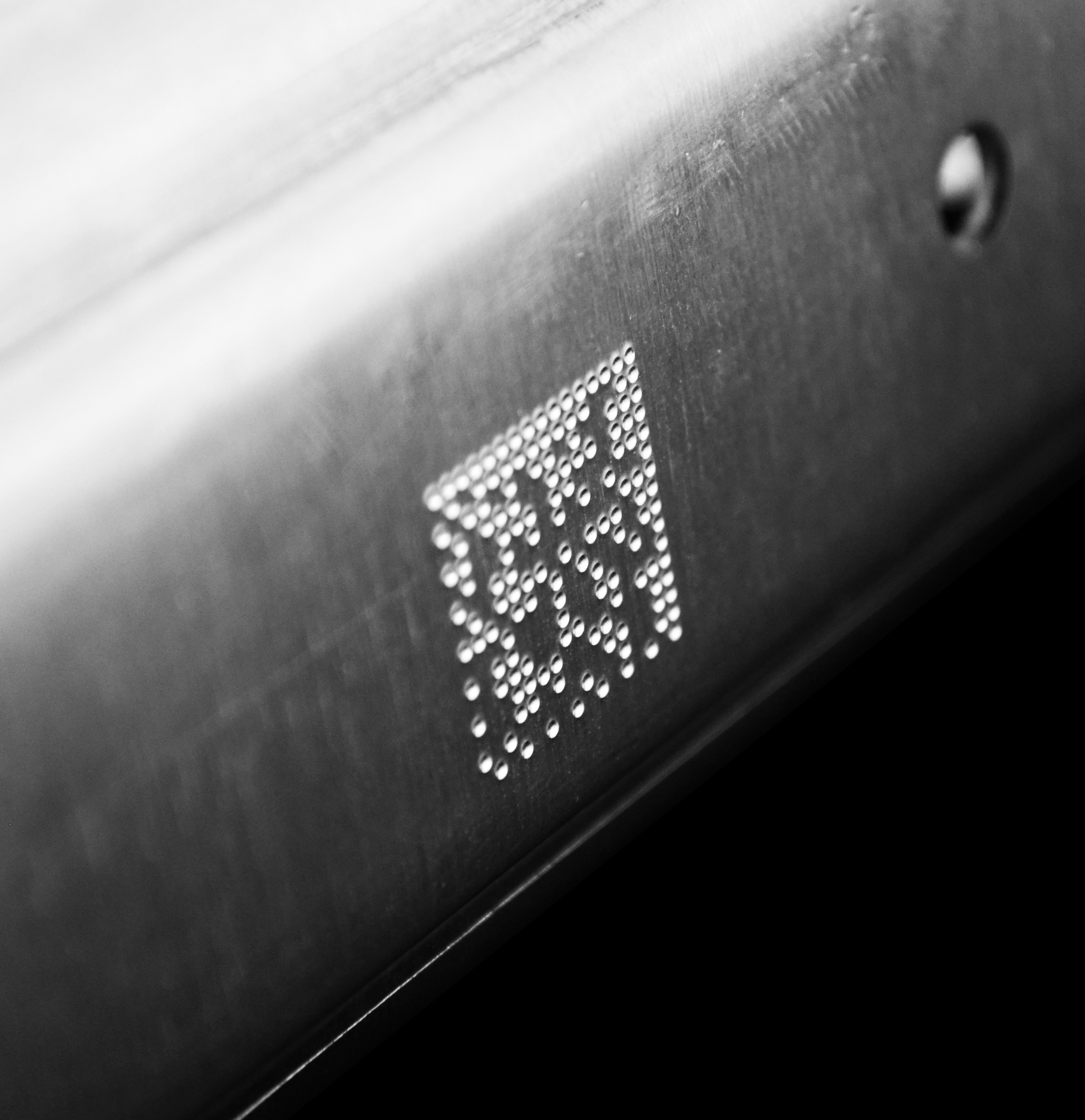

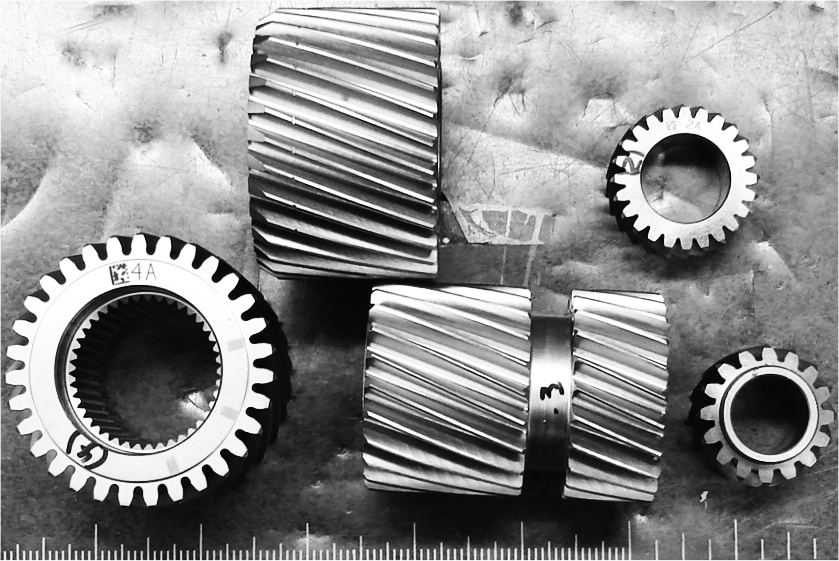

Laser marking machines enable automotive manufacturers to print unique identifiers like vehicle identification numbers (VINs), security codes and two-dimensional (2D) matrix codes onto car parts. Companies use these codes to obtain valuable track and trace data like lot numbers and manufacturing dates. Auto parts laser marking machines engrave these individualized sequences onto components with optimal accuracy and precision at various production stages, ensuring that each code is visible and easily readable.

Using laser engravers to promote part traceability in the automotive industry means achieving all of the following functions:

Quality control: Traceability allows auto part manufacturers to maintain maximum control over production processes and pinpoint stages of production where quality checks would be advantageous.

- Root cause analysis: When all component data is meticulously tracked and compiled in a single location, manufacturers can accurately identify the root causes of potential errors and make improvements accordingly.

- Operational efficiency: Automotive traceability systems like laser marking machines enable organizations to minimize resource waste, boost efficiency and ultimately optimize productivity.

- Product recall: Manufacturing traceability methods generate a permanent paper trail that automotive companies can use to track defective parts in the event of a recall, protecting them against liabilities. Easily traceable components also reduce the costs of product recalls and prevent them from occurring again.

- Customer satisfaction: Companies that use laser markers for traceability can increase quality, improve auto parts and ultimately boost customer satisfaction.

- Counterfeiting prevention: When automotive components have serial numbers and barcodes, it becomes more difficult for individuals to counterfeit products because manufacturers can use these codes to confirm product authenticity.

Quality control: Traceability allows auto part manufacturers to maintain maximum control over production processes and pinpoint stages of production where quality checks would be advantageous.

Quality control: Traceability allows auto part manufacturers to maintain maximum control over production processes and pinpoint stages of production where quality checks would be advantageous.