Dot Peen Markers and Lasers for Military Aircraft Manufacturers

and Aviation Parts Suppliers

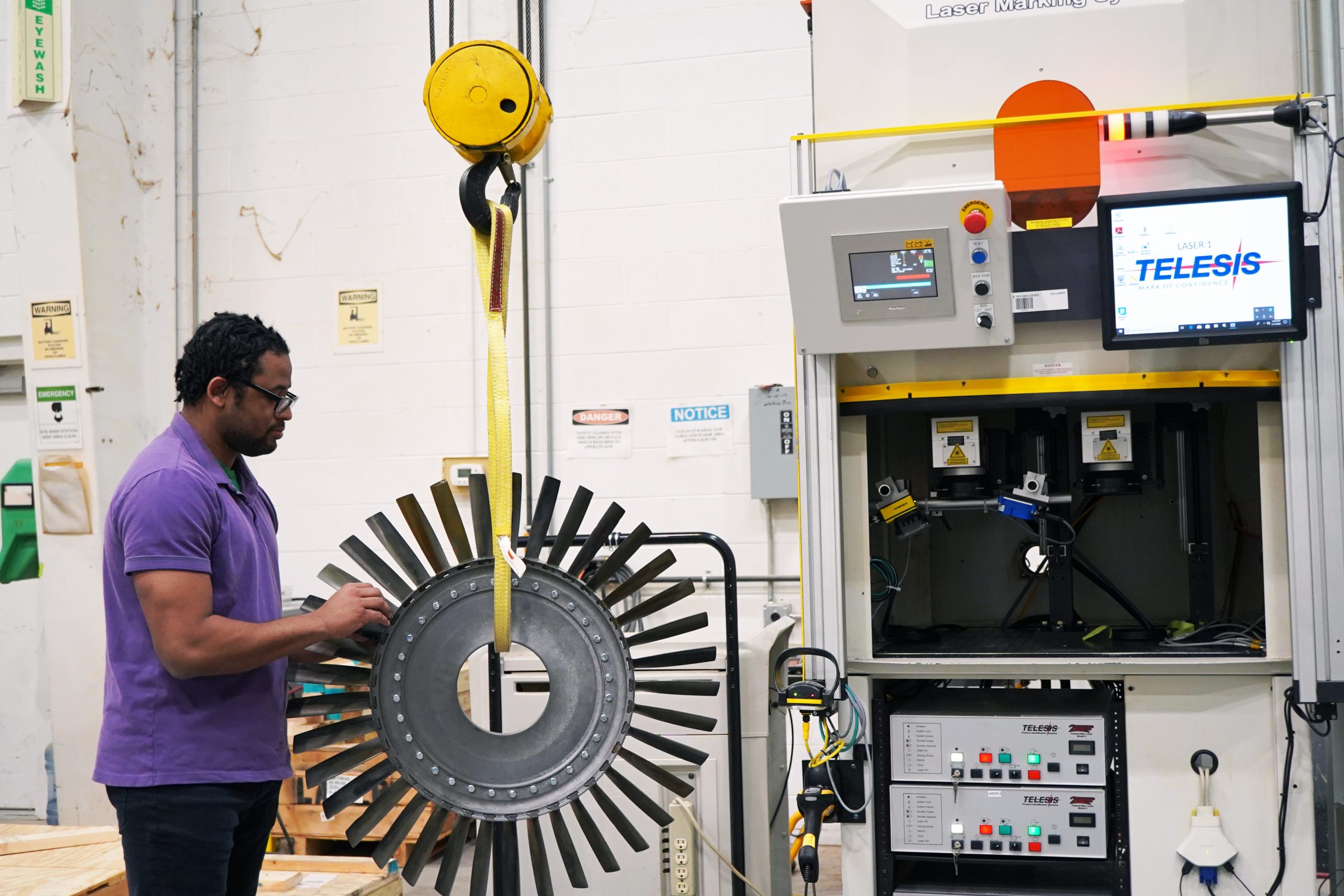

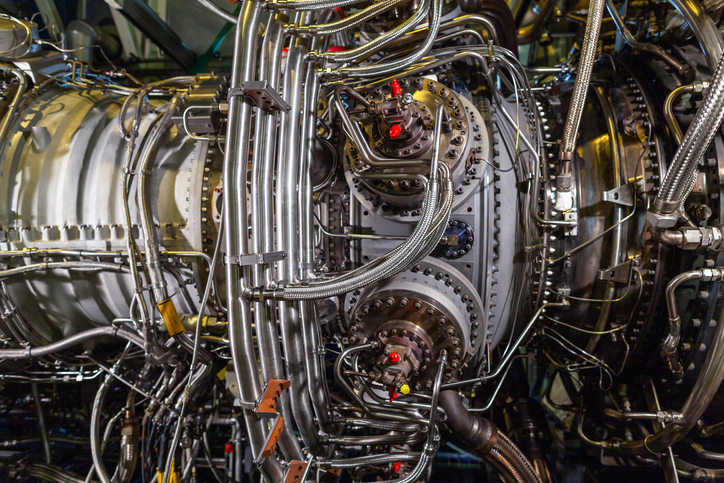

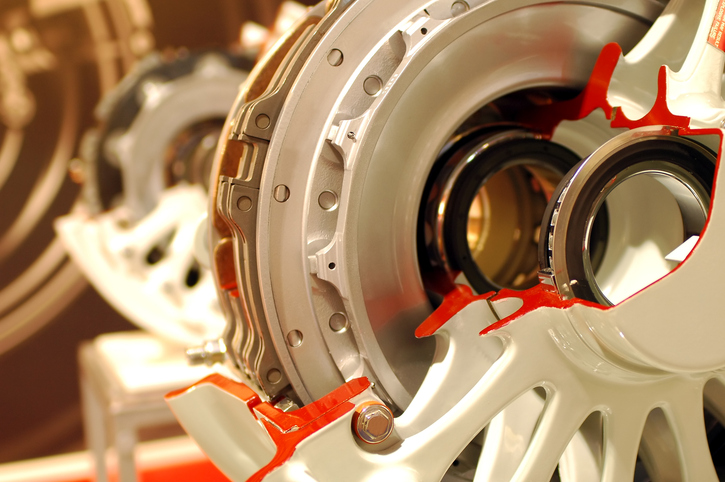

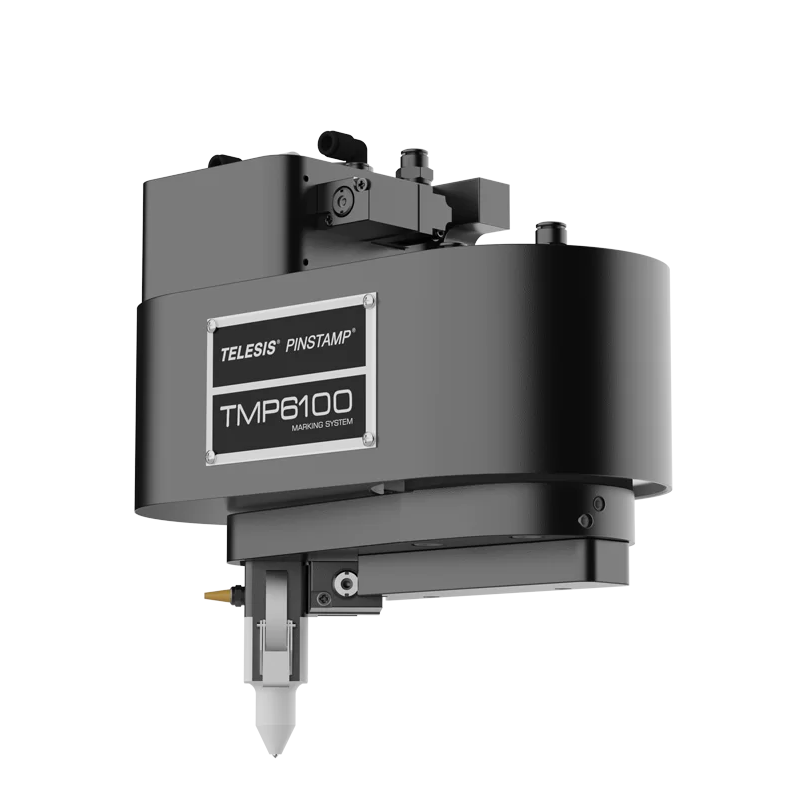

You require a careful approach when marking items that will be used in high-heat environments. Labels, inkjet solutions and RFIDs struggle to stay intact when applied to engine surfaces. Premature wear and smudges are not an option for your production process. Relying on permanent marks from lasers or dot peen markers is the answer to marking hard and nonporous surfaces moving through your facility.

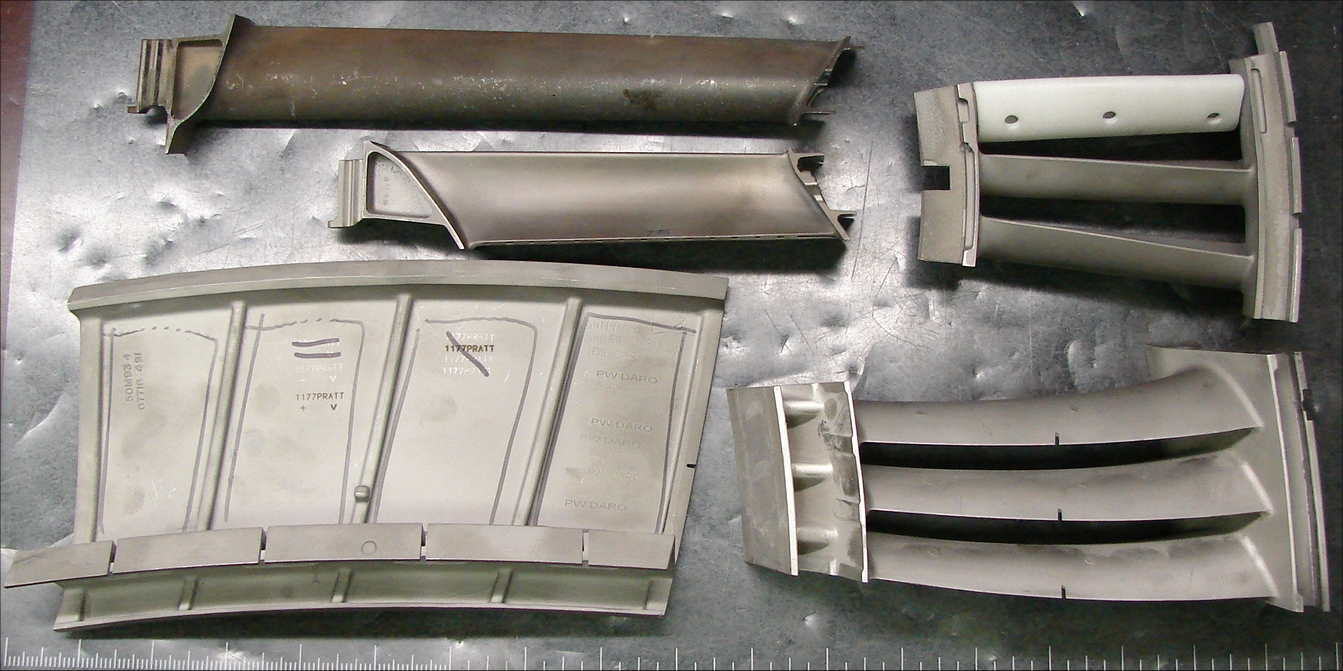

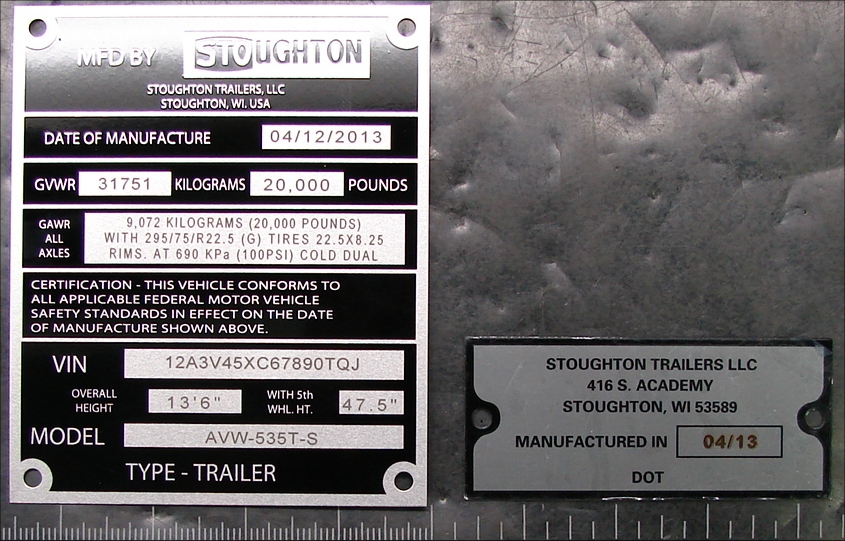

Unique identifiers and security measures help prevent counterfeiting and unauthorized distribution. The traceability of aerospace laser marking and dot peen marking complies with international standards, including ATA Spec 2000, ensuring each component can be tracked throughout its life cycle.

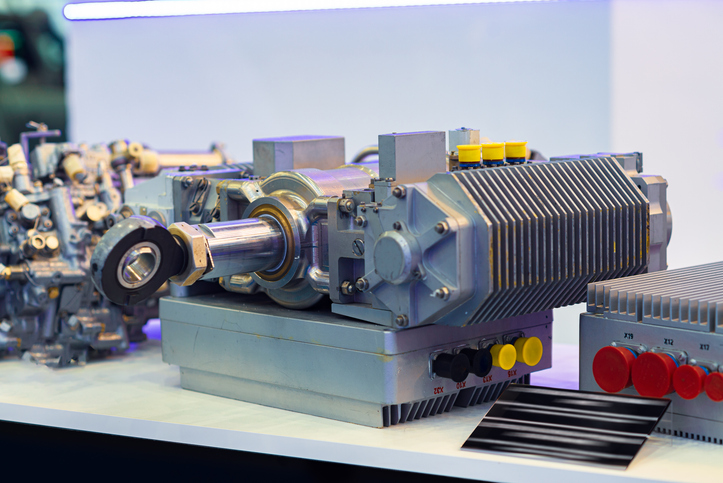

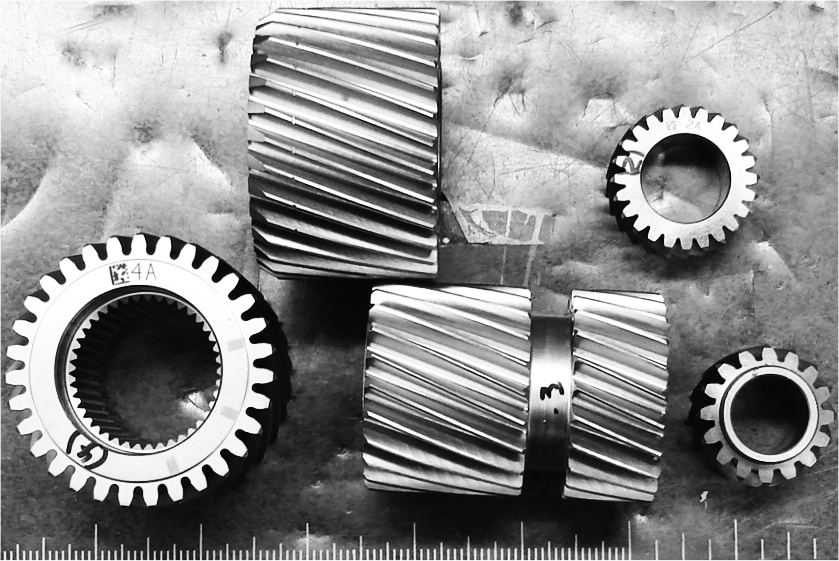

The metals and other materials that aerospace engineering companies and airplane manufacturing companies use can withstand forces and environments that other modes of transportation don’t have to withstand. No other marking system offers the clarity and dependability that a dot peen marker machine offers. Whether your aircraft is designed with titanium, carbide, aluminum, plastics, platinum ceramics or another material, dot peen markers can mark on it and mark fast.