Types of Laser Markers

At Telesis Technologies, Inc., we design several industrial laser markers with outstanding features. Our key models include:

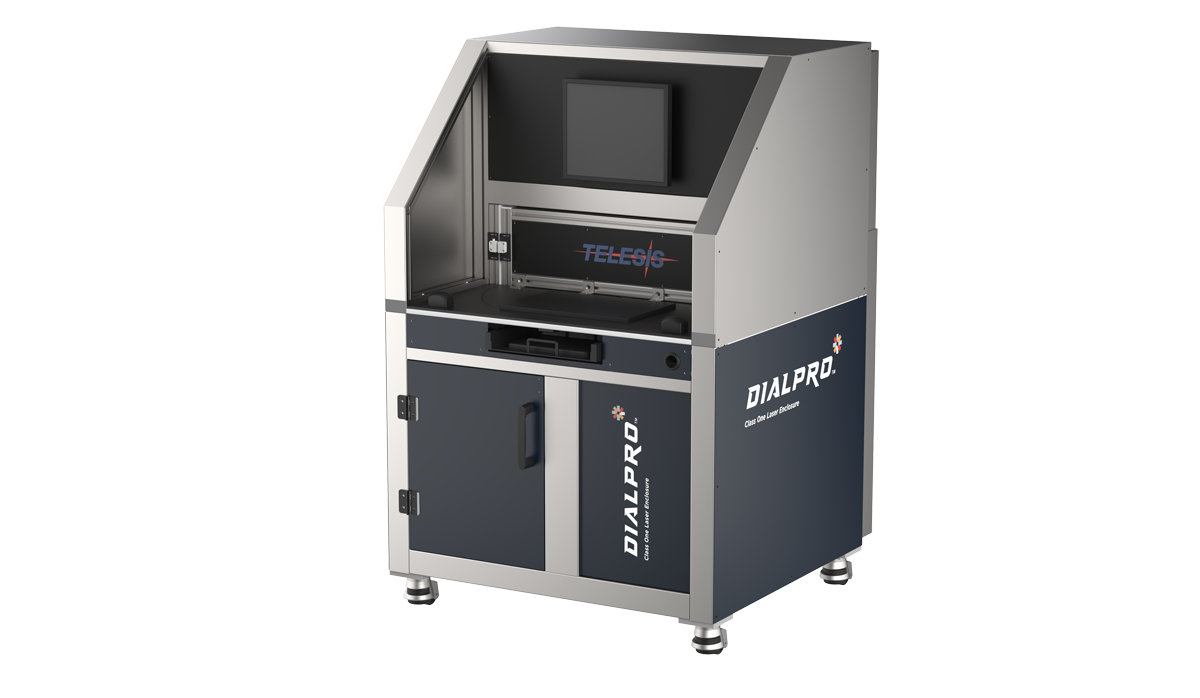

Dual-Head Laser System

As the name suggests, the dual-head laser system allows the operators to use two lasers with one controller. Due to the dual-head design, the system engraves faster and helps increase throughput.

Fiber Laser Markers

Fiber laser markers are versatile machines that are easy to use and require minimal maintenance. They are mostly used for engraving metal and plastic.

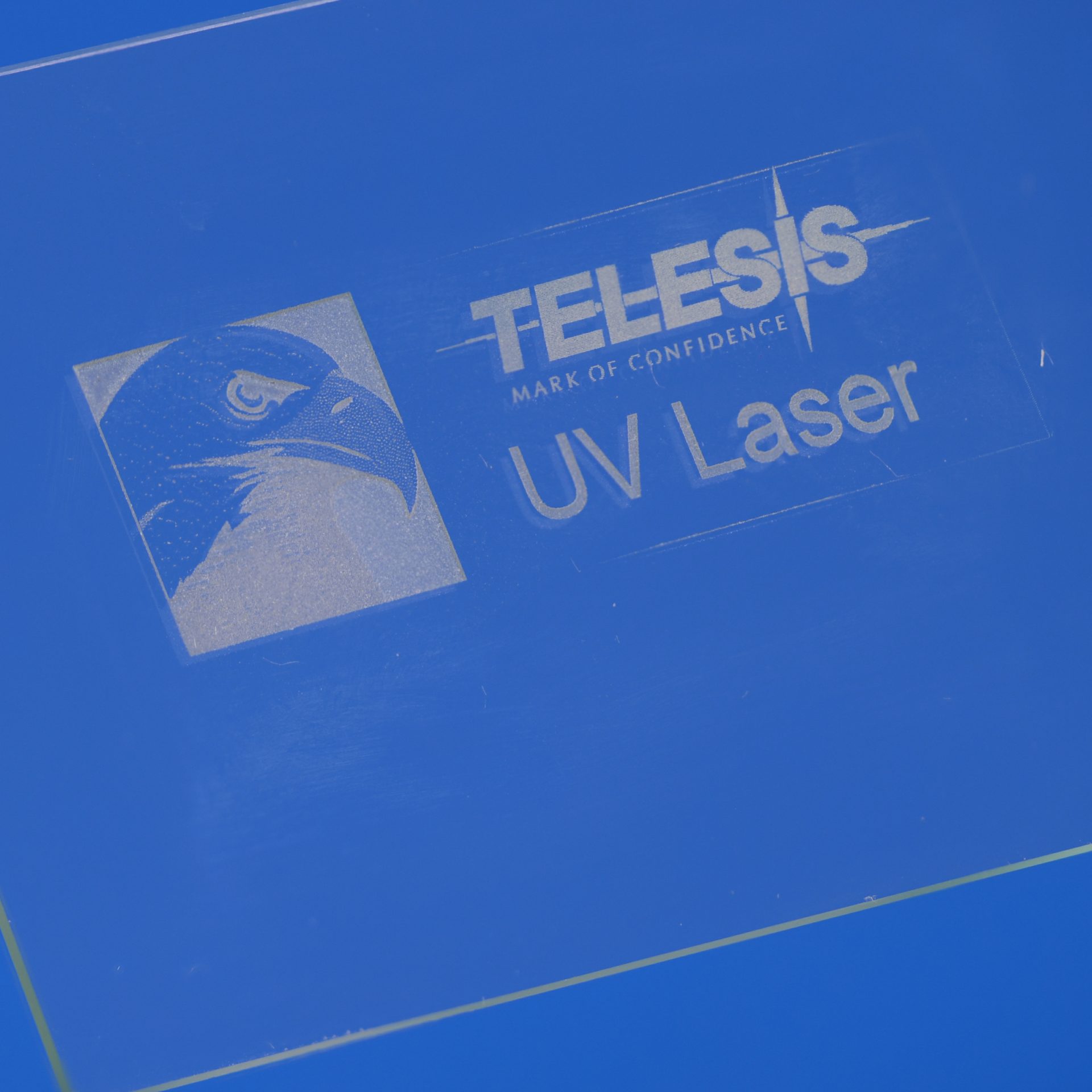

UV Laser Markers

Ideal for cold laser marking, our UV laser markers leverage a 355-nanometer wavelength to reduce heat-affected zones during the laser marking process.

Green Laser Markers

Green laser marking systems are perfect for applications that require high beam quality and stability. The machines have the necessary speed and power for scribing and trimming.

Vanadate Laser Markers

Vanadate laser markers have an excellent beam quality that works well for fine marking and heat-sensitive materials.

CO2 Laser Markers

CO2 laser markers are the perfect choice for high-duty cycle environments. Since these systems require zero consumables, they help speed up label and packaging operations.