The Importance of Laser Marking for Food Packaging

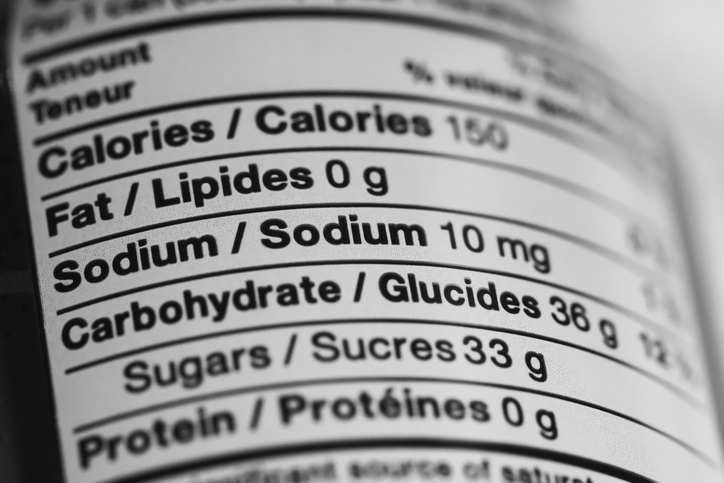

- Ensure regulatory compliance: To maintain regulatory compliance, manufacturers must follow baseline traceability guidelines as outlined by the FDA.

- Enhance food traceability: Manufacturers can streamline food traceability by marking food packaging with unique identifiers. Tracing food improves quality control and efficiency for greater consumer confidence and satisfaction.

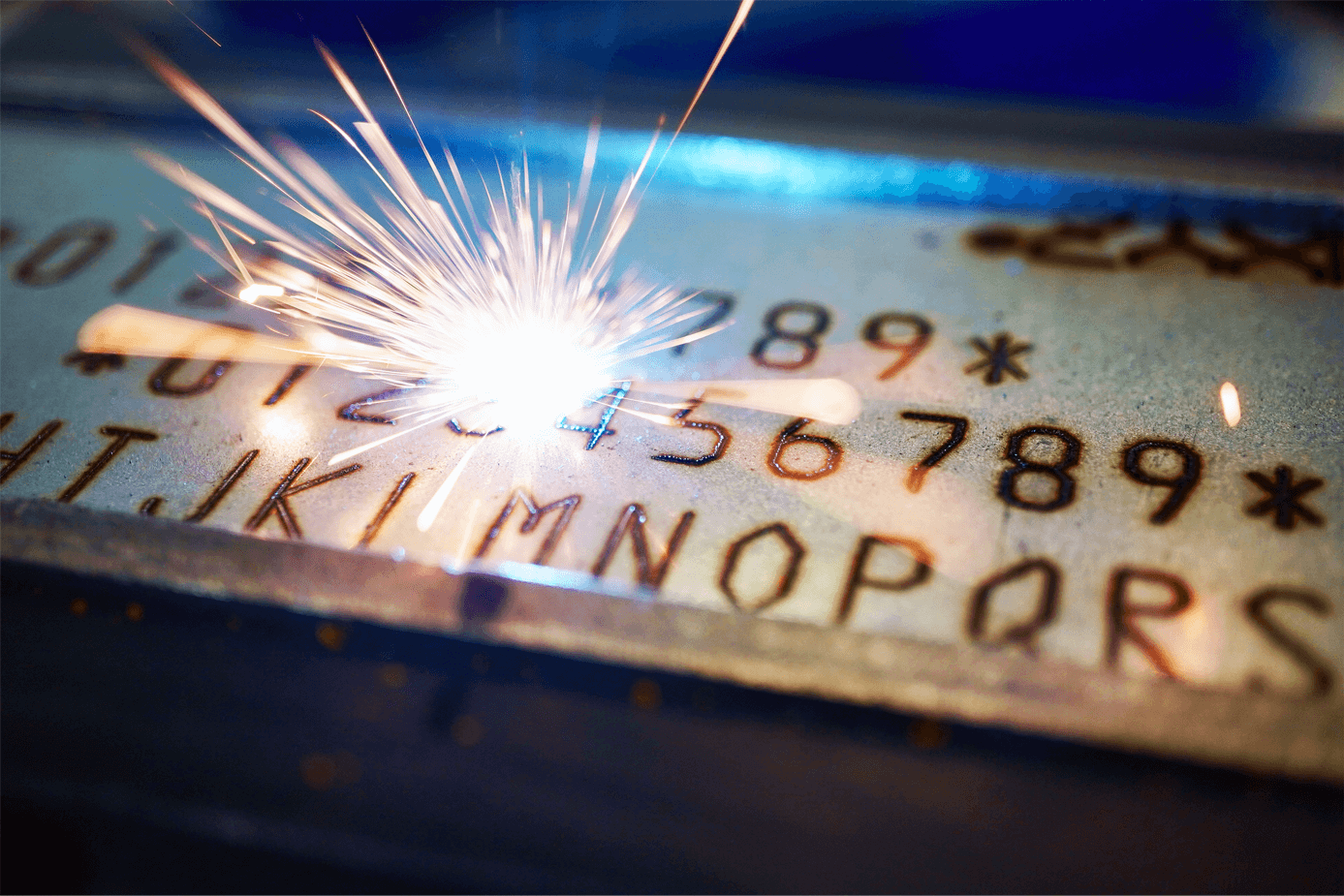

- Boost efficiency and cost-effectiveness: Laser marking is faster and more accurate than other methods. It also requires fewer consumables, lowering environmental impact.

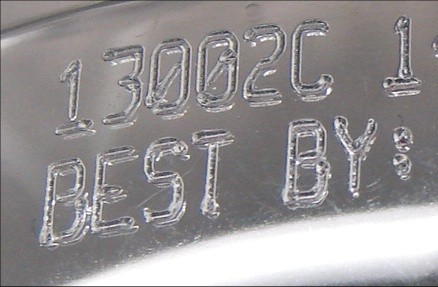

- Get permanent, legible marking: Serial codes and other information should be permanent to increase reliability and confidence. Laser engraving provides permanent marks, which is important for consumer safety and managing product recalls.

- Benefit from material versatility: You can mark various materials with lasers, including plastic, wood, paper, silicone and cardboard, among others.