UV/KRYO laser marker delivers precise, marking on sensitive materials like plastics, glass, ceramics, and medical-grade substrates with minimal heat impact. Ideal for permanent, non-intrusive identification, it ensures traceability and compliance across industries. Built for efficiency, it enhances productivity with reduced cycle times and seamless integration into automated or standalone production setups.

Ultraviolet Power, Precise Marking for All Materials

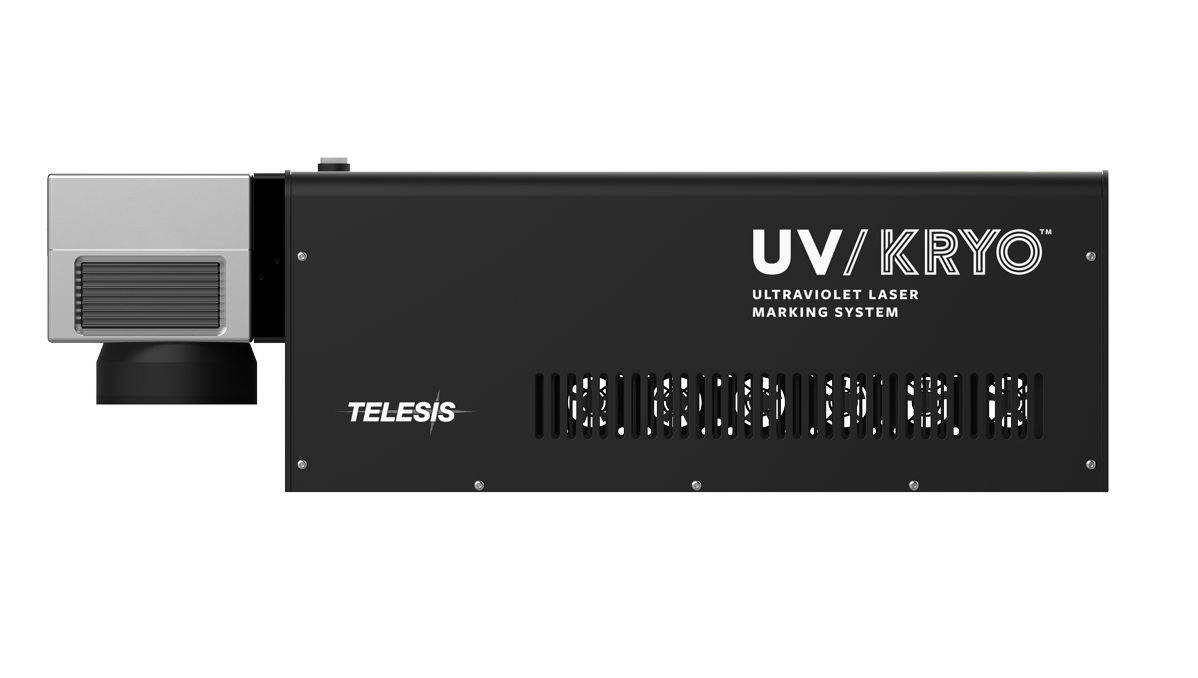

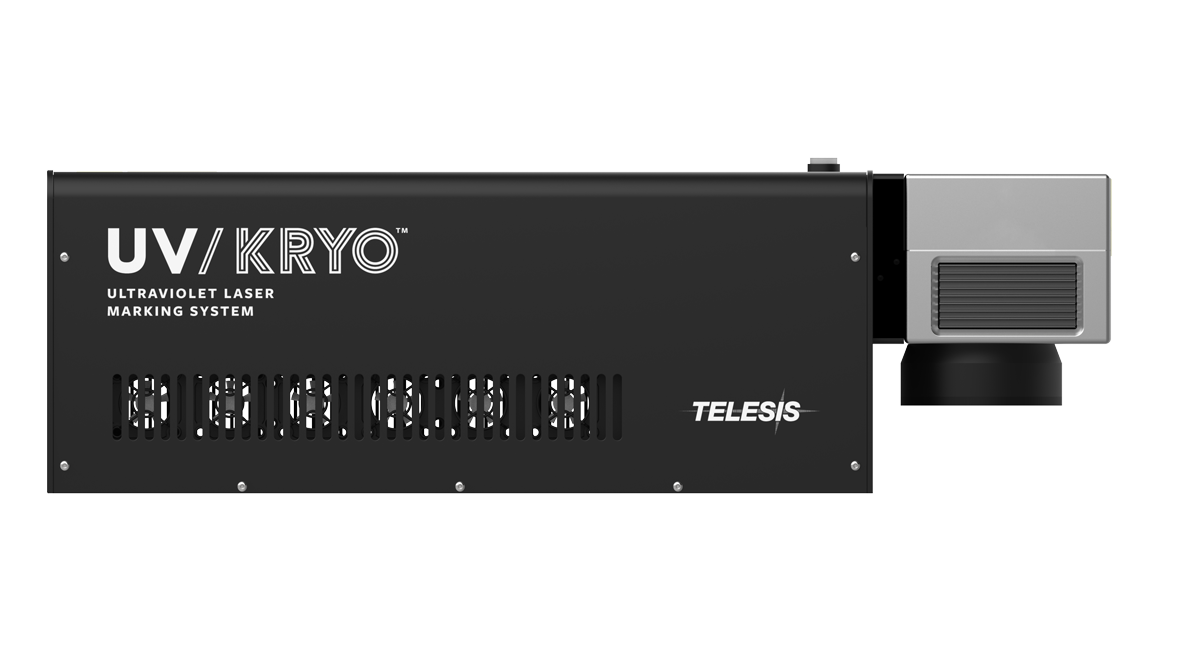

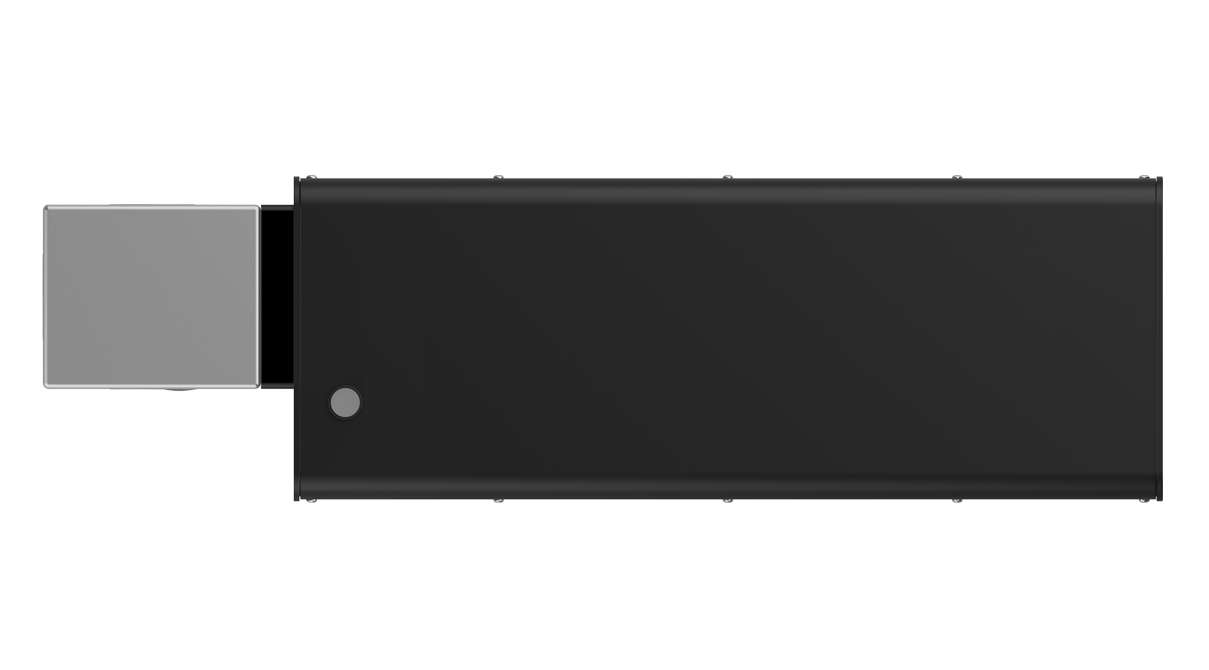

UV/KRYO™

Experience precision and versatility with the Telesis UV/KRYO laser marker. Designed for marking delicate materials, including plastics, glass, and other sensitive substrates, the UV/KRYO delivers high-contrast, permanent markings without causing thermal damage. Its cutting-edge technology ensures crisp, clear results on a wide range of surfaces, making it ideal for industries that demand high-quality, legible marks, such as electronics, medical devices, and packaging. Trust Telesis for reliable, high-performance laser marking solutions that meet your exacting standards.

Request a Quote Download Product Catalog- Laser beam and Q-switched pulse characteristics are optimized for applications that require high beam quality and stability

- Great for high-speed marking on delicate and sensitive electronics components, glass, and medical instruments

- Ideal for general purpose laser marking, scribing, trimming, and other material processing applications

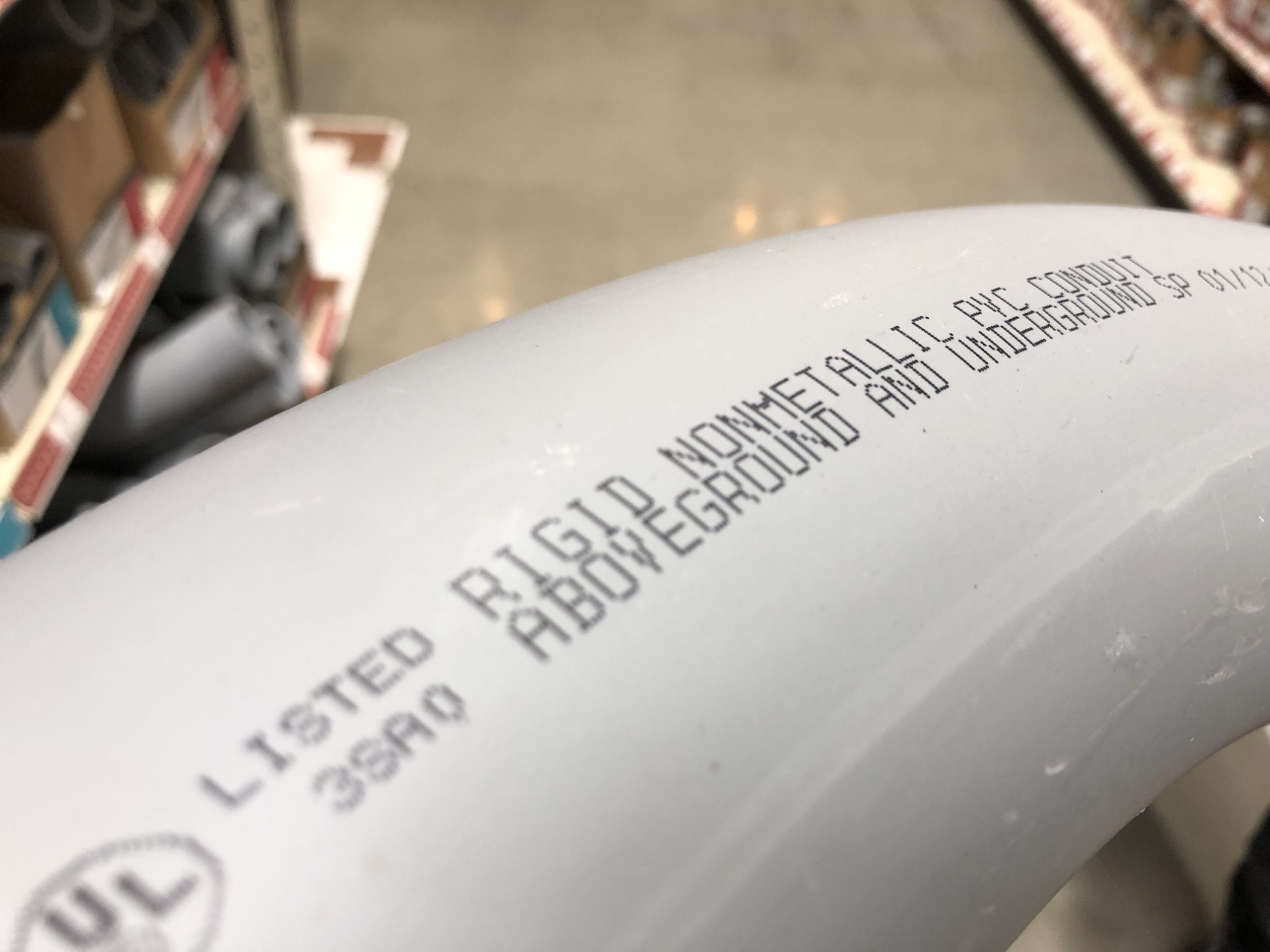

Great for marking:

- HDPE

- Glass

- Ceramics

- Paper + Cardboard

- Foils

- Films

- Ethernet IP

- Fume Extraction System

- iZONIT™

- Mark-on-the-Fly Ready

- Profinet

- Programmable Mounting Post

- Rotary Axis Fixture

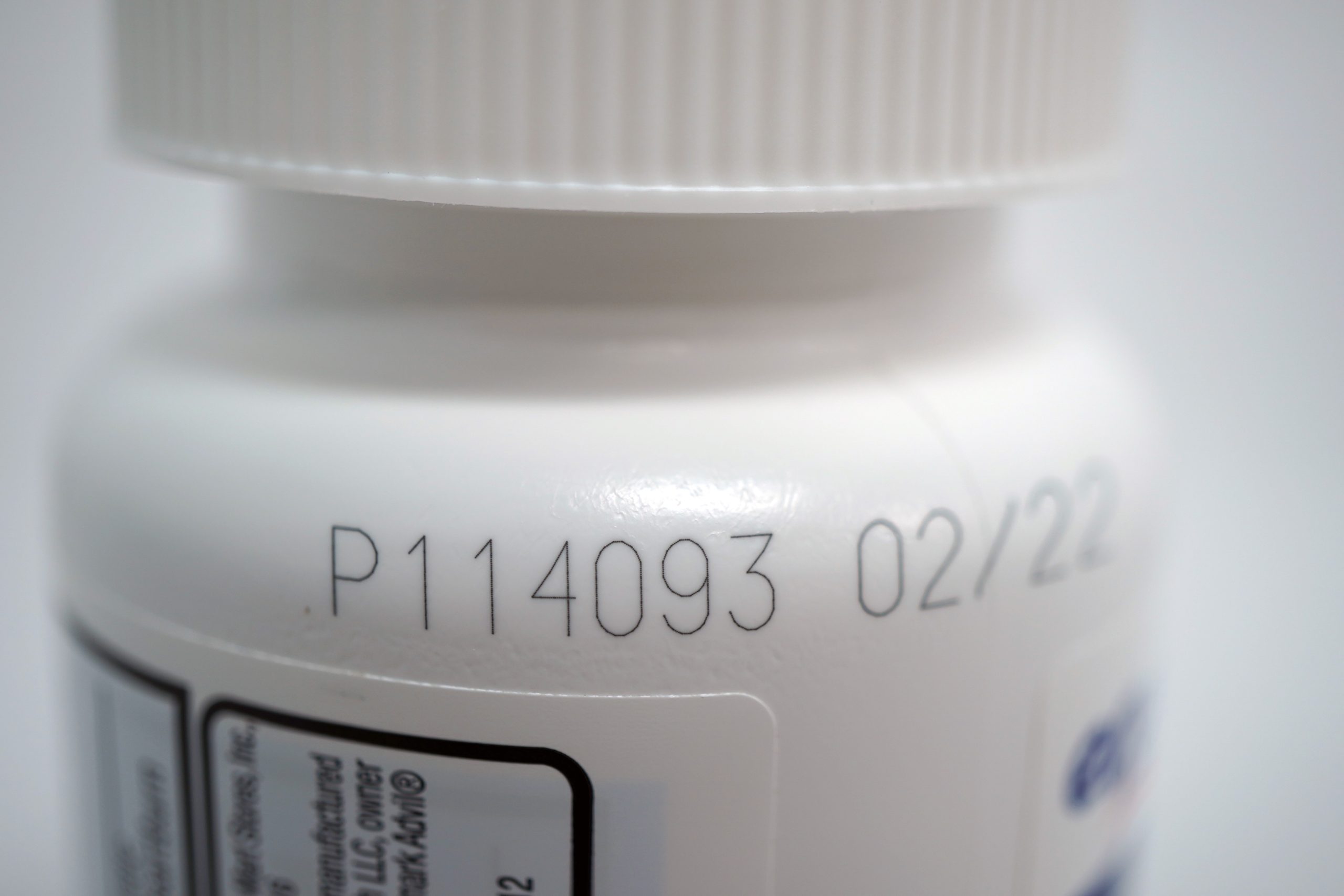

Applications

Markings

Markings on Pill Bottle

Markings

Markings

Specs

Lens Marking Area

F160: 3.54" x 3.54" (90 mm x 90 mm)

F254: 6.69" x 6.69" (170 mm x 170 mm)

F330: 9.05" x 9.05" (230 mm x 230 mm)

F420: 11.81" x 11.81" (300 mm x 300 mm)

Lens Working Clearance

F160: 8.25" (210 mm)

F254: 11.81" (300 mm)

F330: 15.35" (390 mm)

F420: 19.40" (495 mm)

Laser Head Dimensions

23.06" L x 7.01" W x 6.7" H

586 mm x 178 mm x 170 mm

Note: Height without lens

Ensure Crisp, High-Contrast Results with the Telesis UV/KRYO

The Telesis UV/KRYO laser marker is engineered for exceptional marking performance across even the most sensitive materials. With a specialized ultraviolet wavelength, the UV/KRYO ensures crisp, high-contrast results while minimizing the risk of thermal damage to substrates like plastics, glass, ceramics, and medical-grade materials. This makes it the ideal choice for industries where product integrity is crucial.

The UV/KRYO’s ability to mark at a lower temperature delivers unparalleled accuracy, making it perfect for applications that demand permanent, non-intrusive identification such as serial numbers, barcodes, and logos. Its precision and reliability offer manufacturers an edge in traceability, branding, and compliance—particularly in sectors like electronics, medical devices, automotive, and packaging.

With the UV/KRYO, quality and efficiency go hand in hand. Its advanced capabilities reduce cycle times, increase productivity, and minimize waste. This laser system seamlessly integrates into production environments, offering robust performance in both standalone and fully automated configurations.

Experience precision and versatility with the Telesis UV/KRYO laser marker. Designed to be powerful, but still able to mark delicate materials, including plastics, glass, and other sensitive substrates, the UV/KRYO delivers high-contrast, permanent markings without causing thermal damage. Its cutting-edge technology ensures crisp, clear results, making it ideal for industries that demand high-quality, legible marks, such as electronics, medical devices, and packaging.

The Telesis UV/KRYO laser marker delivers precise, high-contrast marks with cold marking technology, ideal for delicate materials. Built for high-volume production, it ensures reliable, permanent identification on plastics, glass, ceramics, and coated metals. Its compact design allows easy integration, making it perfect for industries demanding quality and precision.

From high-volume electronics to medical equipment and packaging, the Telesis UV/KRYO laser marker delivers unmatched marking capabilities that provide permanent, reliable identification without compromising material integrity. Meet the most stringent requirements for product marking with the trusted performance of Telesis UV/KRYO.

- Cold Marking Technology: Ultraviolet wavelength ensures minimal heat impact, perfect for heat-sensitive materials.

- High-Contrast Marking: Produces clear, legible marks that enhance product traceability and brand recognition.

- Versatile Applications: Suited for a wide range of materials including plastics, glass, ceramics, and metals with coatings.

- Superior Reliability: Designed for continuous, high-volume production environments, ensuring long-lasting performance and consistent results.

- Flexible Integration: Compact design and configurable interfaces allow easy integration into existing production lines.

Complete your System

Our UV/KRYO pairs with the following Telesis enclosures, workstations, and accessories to provide you with a complete end-to-end marking system.