Types of Laser Marking Machines for Stainless Steel Products

You can use several types of laser machines to engrave stainless steel, including:

Stainless steel is vital in various industries, including the medical, consumer goods, aeronautics and automotive sectors. Its wide use is due to its corrosion resistance, versatility and durability. Laser engraving stainless steel presents a superior alternative to other marking methods. However, using the right laser marking equipment is crucial to ensure the mark’s quality and longevity.

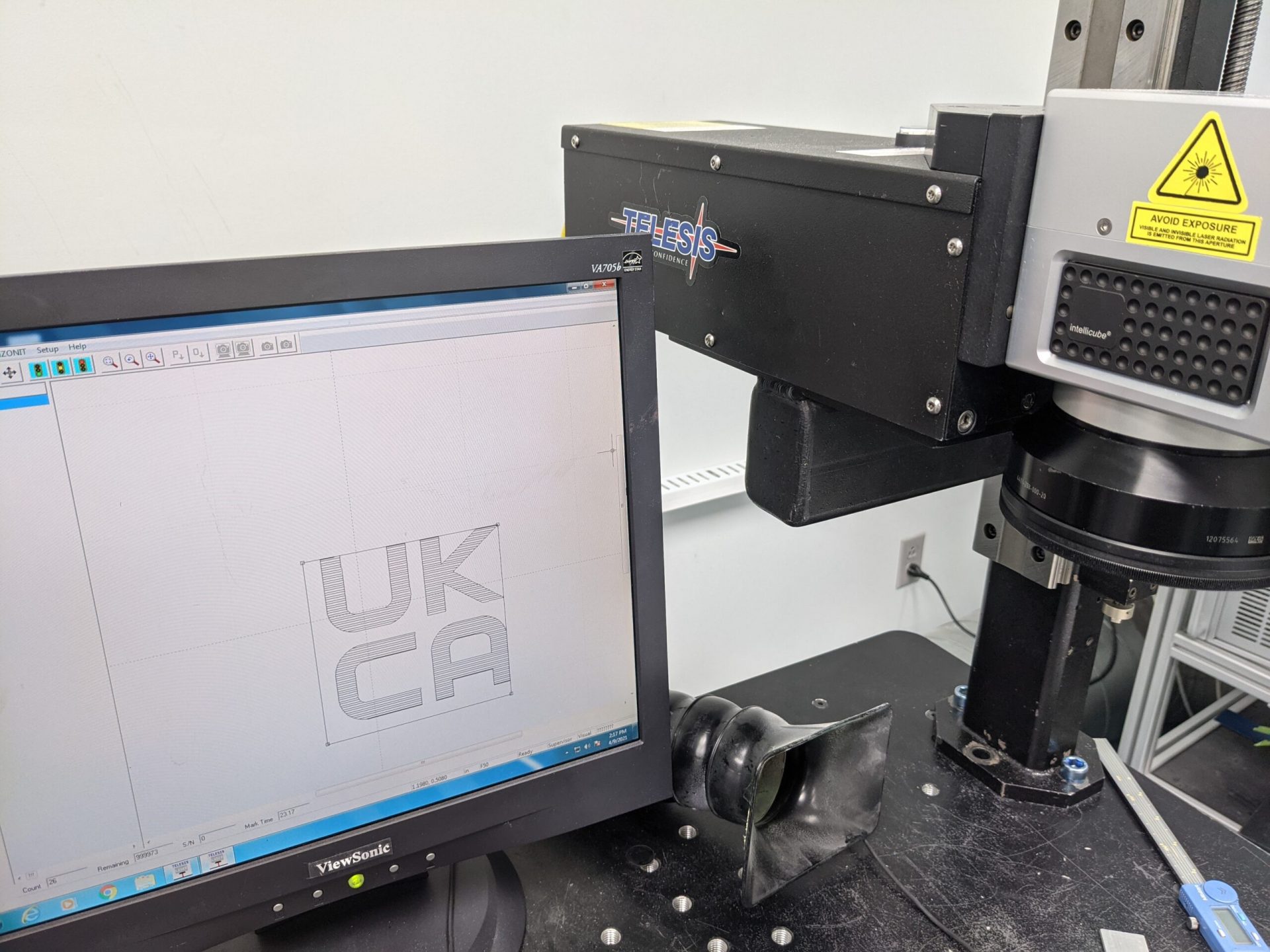

Telesis Technologies, Inc. provides robust laser engravers for stainless steel. We use Industry 4.0 solutions like AI, our proprietary Merlin® platform and robotic integration to enhance the engraving process and achieve precise results.

Contact UsLaser engraving stainless steel has many advantages that can save time and increase manufacturing output. Some of the benefits include:

Engraving stainless steel is suitable for multiple applications, from labeling automotive parts to serializing medical devices.

Laser engraving stainless steel creates permanent, high-precision markings that resist corrosion, heat and wear.

You don’t need any consumables to engrave with a laser, saving you money and lowering your environmental impact.

Lasers provide a cost-effective, rapid marking process that involves minimal equipment maintenance.

Stainless steel is common in numerous sectors thanks to its corrosion resistance and durability. Some typical applications of laser technology for stainless steel include:

Medical Devices and Surgical Equipment

Data Matrix Codes

Logo Engravings

You can use several types of laser machines to engrave stainless steel, including:

Green lasers work best on materials requiring high beam quality and are ideal for cold marking applications on heat-sensitive substrates.

UV lasers should be your first choice if you need precise, corrosion-resistant marking. These units produce clear, sharp micro-markings.

Fiber laser markers are an eco-friendly, low-maintenance option and provide high-contrast, precise markings.

Laser engraving stainless steel is a relatively straightforward process. Before you begin, have all the protective equipment outlined in your user manual. The steps are as follows:

We at Telesis Technologies, Inc. put you first by providing precise, reliable laser equipment to enhance your facility’s productivity. With cutting-edge tools and impeccable customer service, we are the pioneers of permanent engraving. Here’s how we go above and beyond: