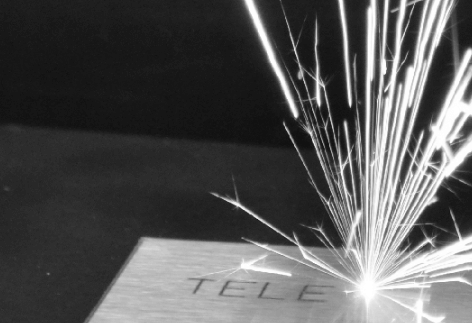

Laser Marking Systems for Construction & Housing

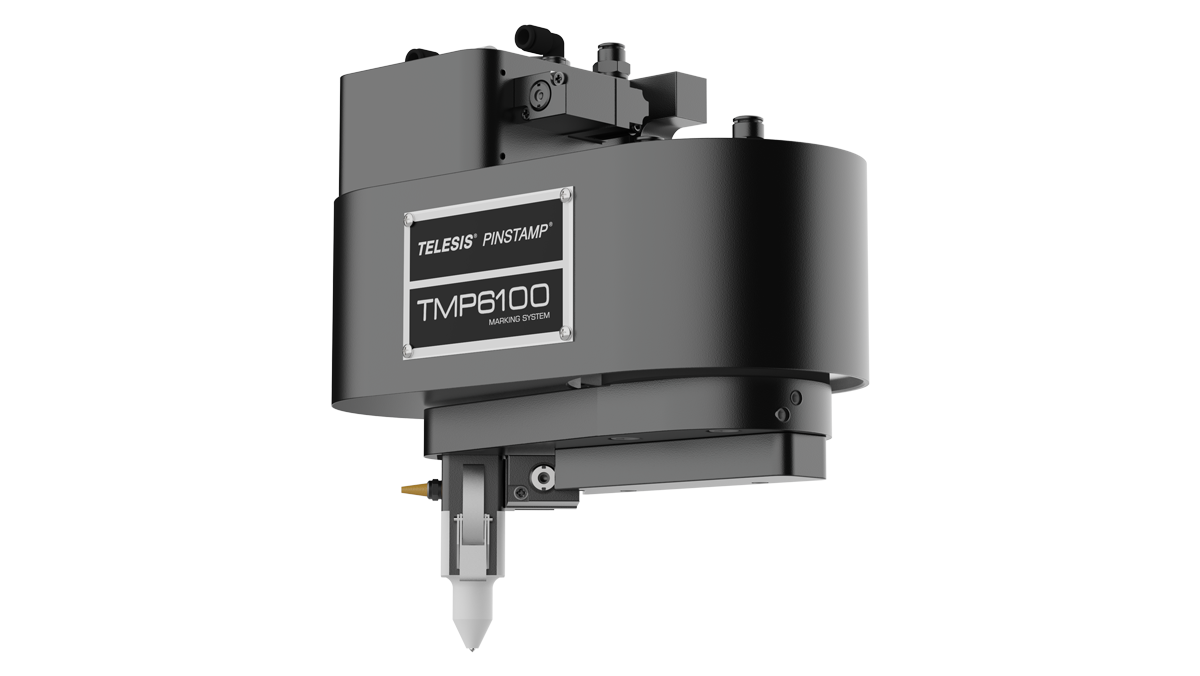

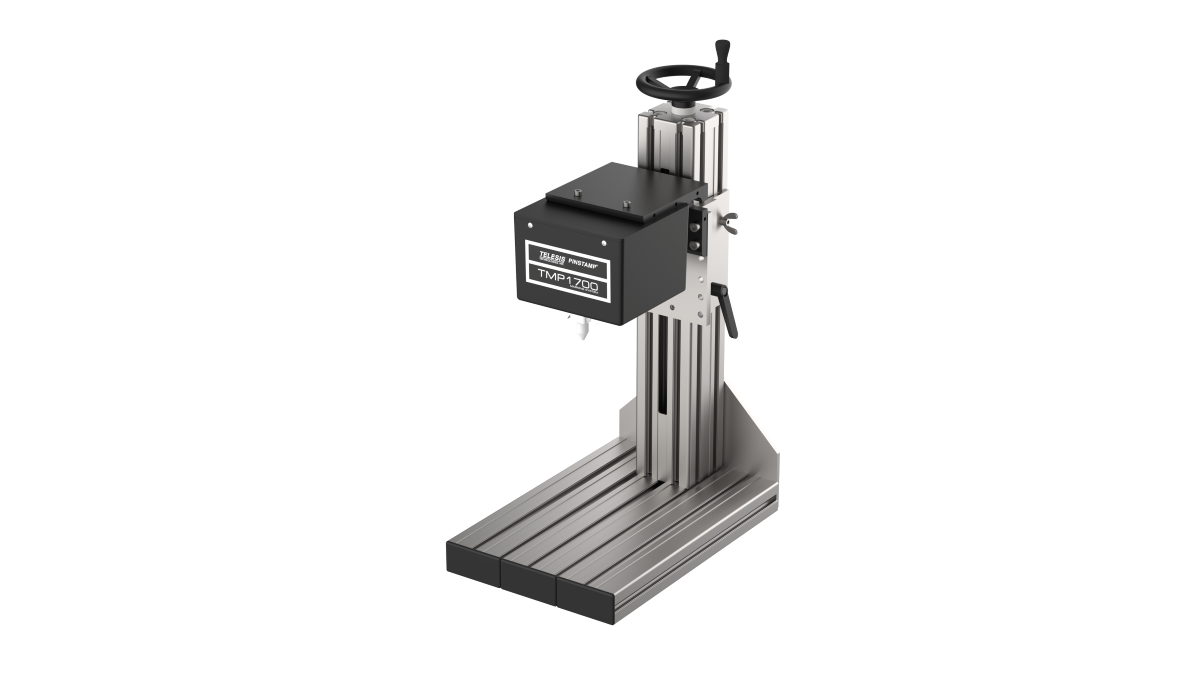

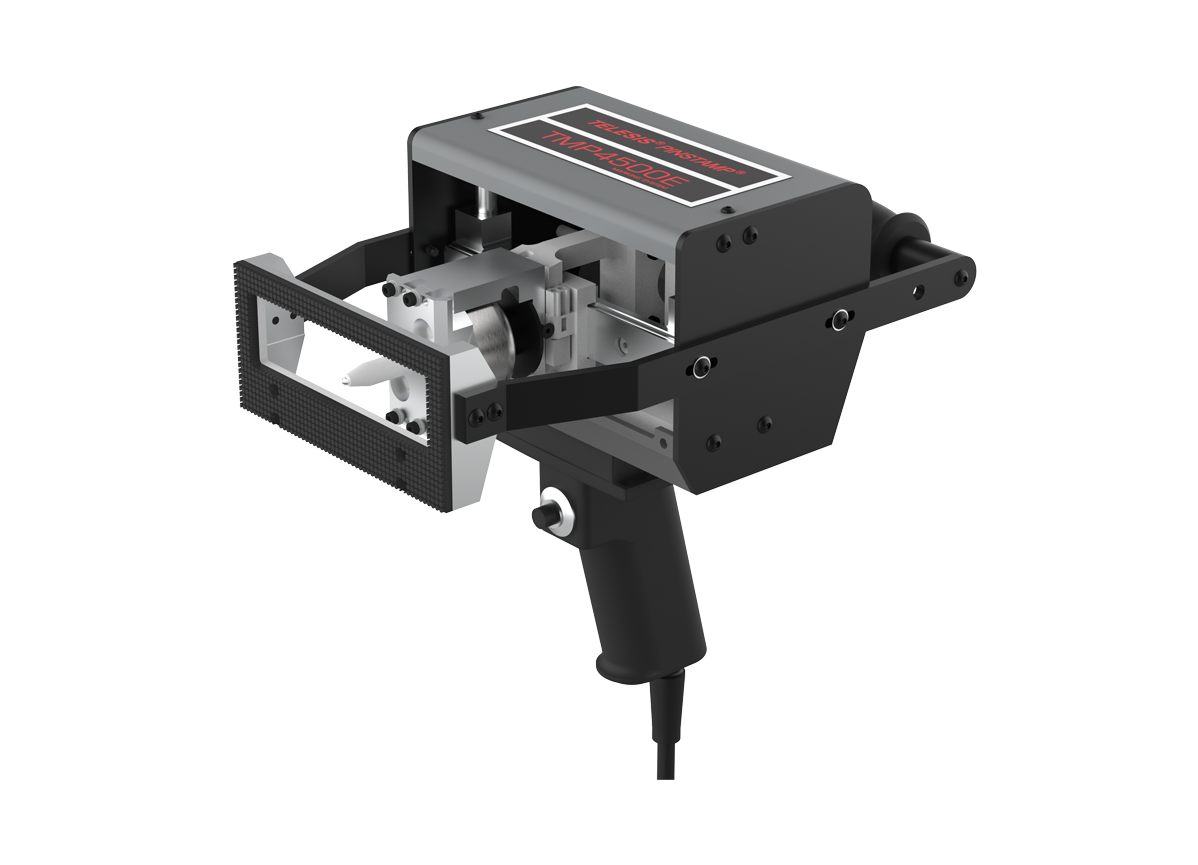

Telesis builds tools for the most demanding manufacturers. You need reliability, precision, and proven effectiveness, and we can provide just that for your marking solutions in the construction and housing industry. Our equipment creates permanent marks, labels, and identification information on glass, stainless steel, hard metal, wood, plastic, composite products, rubber, vinyl, and more.