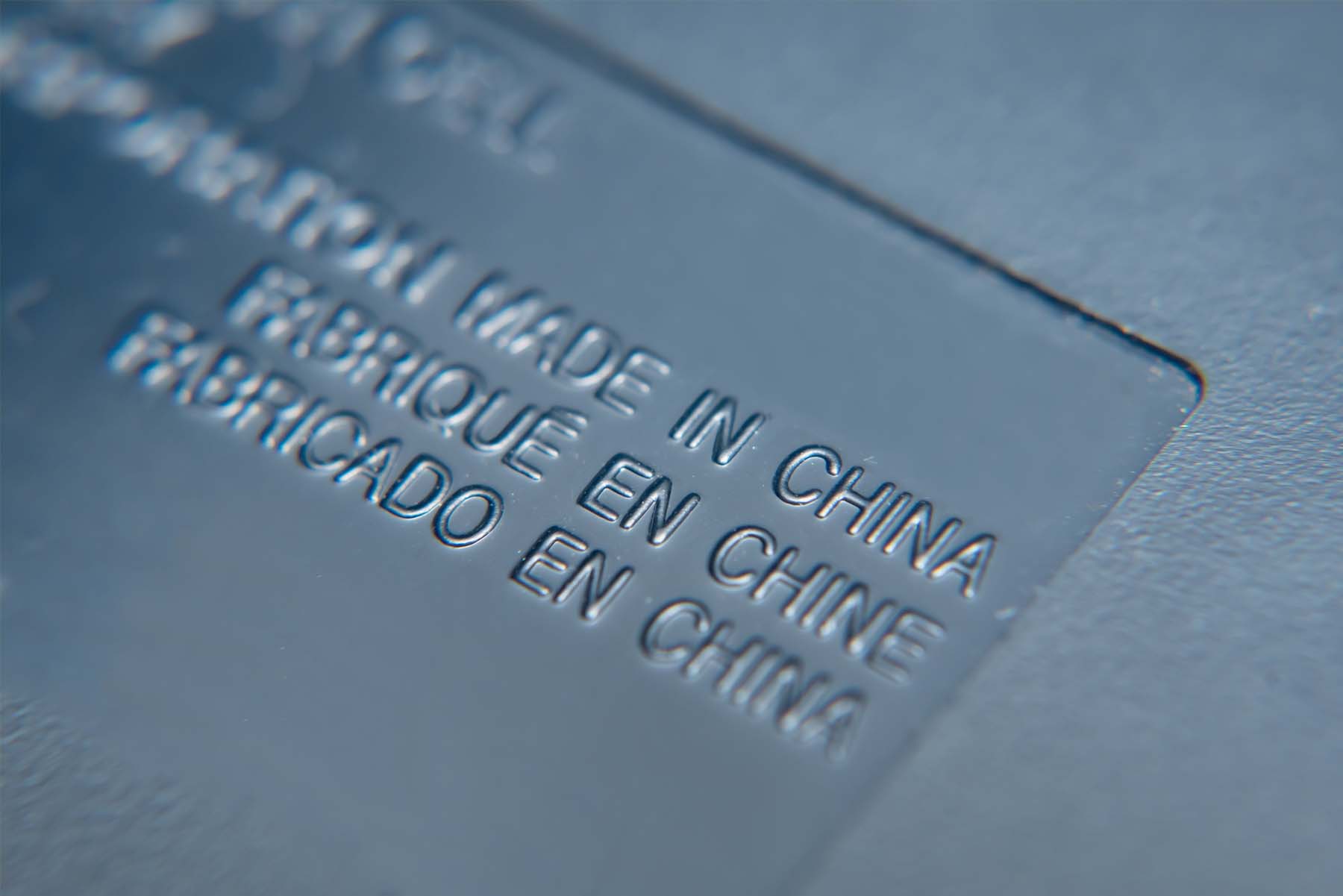

Laser Engraver for Plastic

Whether you’re already in the plastic industry or looking to expand your business, laser engraving your plastic parts can reduce labor costs and help improve your return on investment. It also presents a practical way for your business to save money and time and lower its environmental impact. That’s why it’s crucial to choose the right laser equipment to ensure quality results.

Using Industry 4.0 systems like AI, robotic integration and our proprietary Merlin® software, Telesis Technologies, Inc. provides robust laser engravers for plastic that can increase your facility’s productivity.