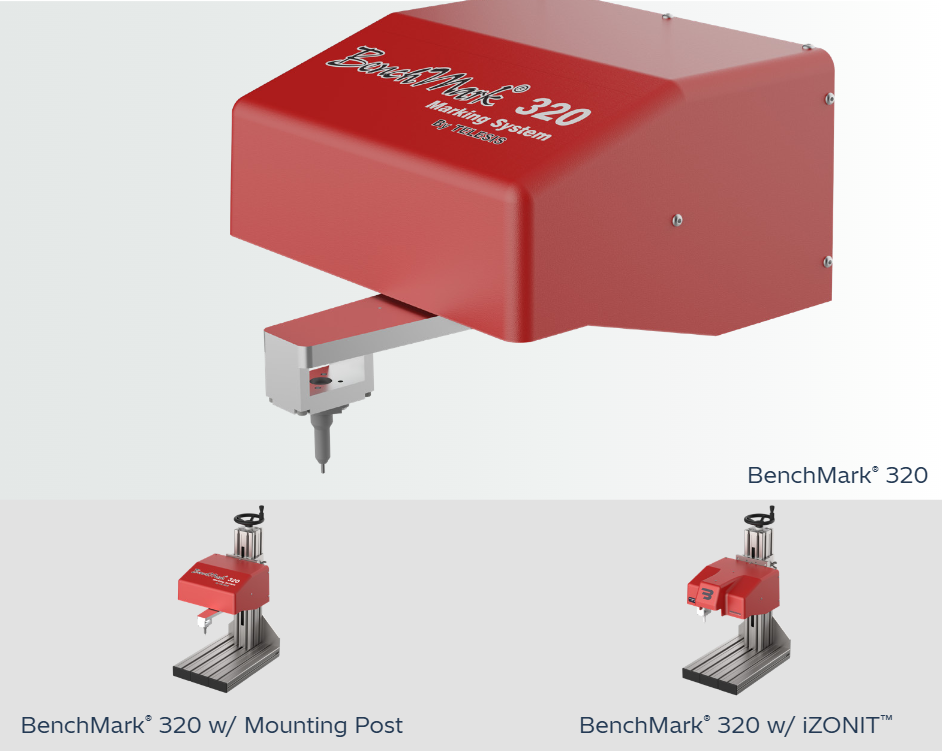

The BenchMark® 320 is a fully electric system, eliminating the need for compressed air and reducing maintenance costs. Integrated with Merlin® software, it offers a simple, user-friendly interface—an efficient, affordable solution for growing operations.

Electric Dot Peen Marker with Vision Technology

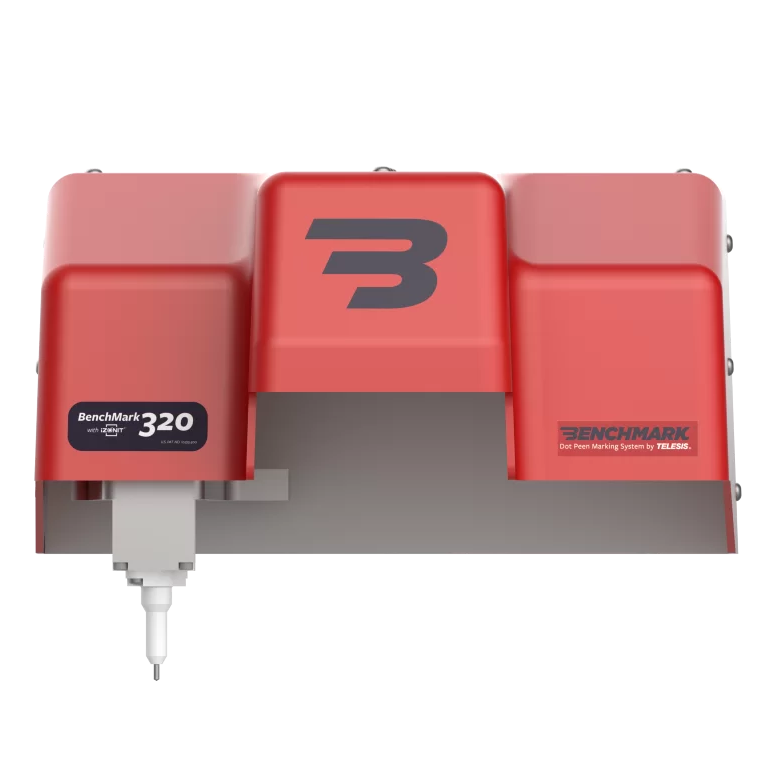

BenchMark320® with iZONIT™

The Telesis BenchMark® 320 with iZONIT™ is a powerful, high-performance marking solution designed to make permanent marking simpler, more precise, and more versatile for a wide range of industrial applications. This plug-and-play system is ready to work straight out of the box, offering immediate efficiency for production lines and standalone workstations alike. Built with a fully electric design, the BenchMark® 320 operates without the need for compressed air, making it a cost-effective choice with a low total cost of ownership. The system’s deep marking capabilities ensure robust, durable marks on metals, plastics, and other challenging materials, making it suitable for applications where mark clarity and longevity are critical.

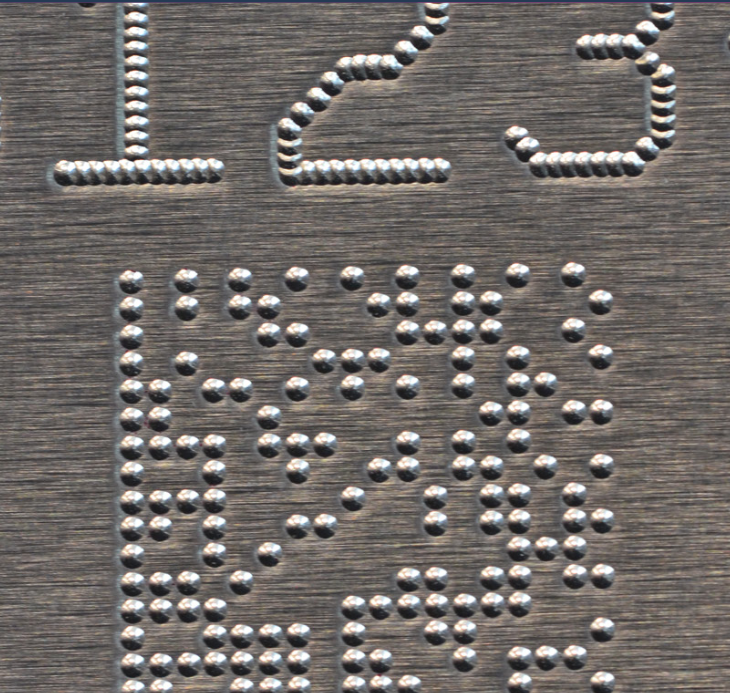

The BenchMark® 320’s advanced iZONIT™ technology elevates accuracy with a “what you see is what you mark” interface, allowing operators to visualize, refine, and confirm mark location directly on-screen before the mark is made. This feature is particularly valuable for complex or high-value parts where marking precision is essential. The user-friendly software interface streamlines setup and operation, empowering users to easily mark a variety of shapes and materials. The system’s 100mm x 150mm (4.0 x 6.0 inch) marking area accommodates everything from simple text and serial numbers to intricate graphics, 2D matrix codes, and QR codes, ensuring flexibility for diverse production needs.

- Visualize the mark before it’s permanent

- Refine mark location using a simple on-screen interface

- Mark differently shaped parts with ease

- Control equipment while maintaining a secure operating distance

- Maintain constant visual reference of marking on the line

- Rugged, Low-Maintenance X/Y Platform: Built to endure tough conditions with minimal upkeep.

- Compact, Contaminant-Resistant Head: Perfect for production lines where reliability is critical.

- Material Versatility: Marks a wide range of materials, including plastics and hardened steel up to RC60.

- Easy Integration: Seamlessly interface with PLCs and host computers to streamline operations.

- Interchangeable Marking Pin Sizes: Adjust marking depth between 0.001″ to 0.018″ (0.03 mm to 0.34 mm)

- Automated Marking Functions: Automatically generate serial numbers, time, date, and shift codes.

- Bar Code Scanner

- Foot Switch

- iZONIT™ Vision Technology

- Marking Head Extension Cables

- Mounting Post

- Oil-Resistant Fabric Boot

- Push Button Station

- Rotary Fixture

- System Computer

- Touch Screen Controller

- Various Marking Pins

Applications

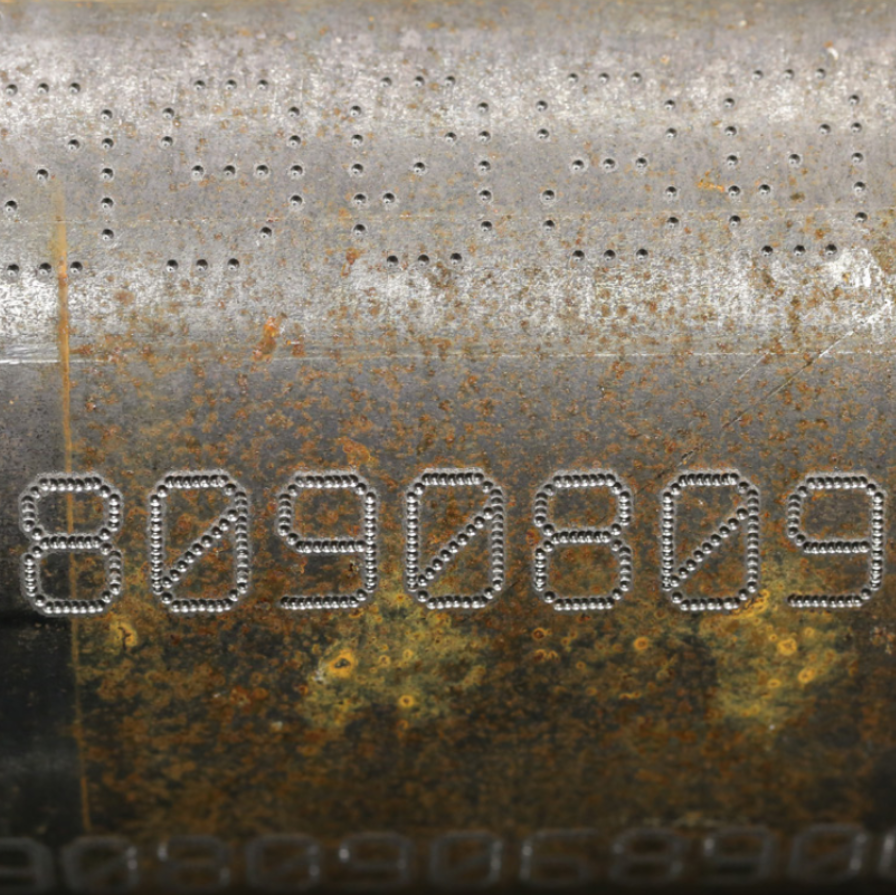

2D Letters & Numbers on Metal

2D QR Code on Metal

2D Serial Numbers on Metal

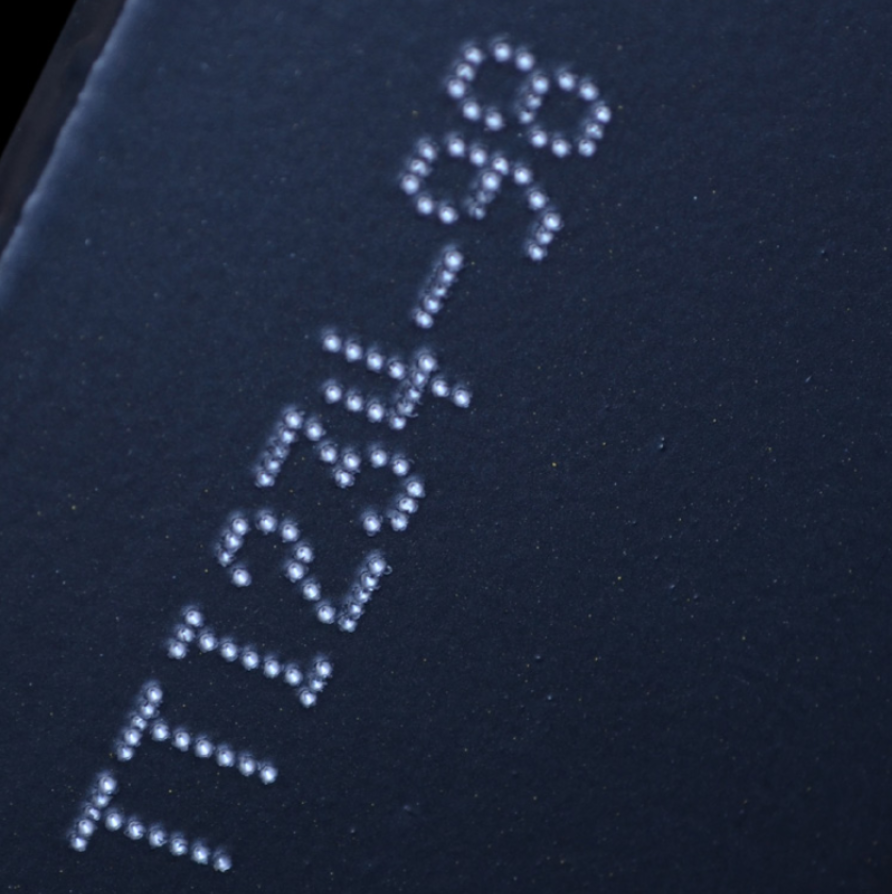

2D Letters and Numbers on PVC

Specs

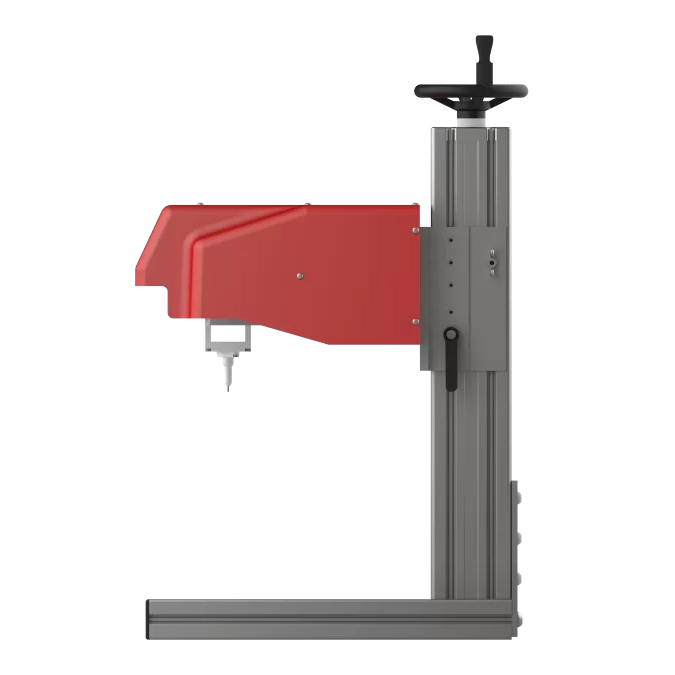

Head Dimensions

8.41" H x 11.28" W x 13.32" D

213.7 mm x 286.5 mm x 338.3 mm

Marking Area

4.0 in x 6.0 in

101 mm x 152.4 mm

Material Compatibility

Soft plastics to hardened steel (up to RC60)

Marking Depth

0.001 – 0.018 in

0.03 – 0.34 mm

Connectivity

PLC, host computer interface

Controller(s)

BM470 (Fixed Button)

TMC520 (Touch Screen)

Merlin III w/ PC

Benchtop Dot Peen Marking with Vision Technology

Ergonomically designed for ease of use, the BenchMark® 320 simplifies part loading and positioning, reducing operator strain and increasing overall efficiency. Its compact footprint fits seamlessly into various production environments, whether as a stationary marking solution or integrated into high-speed production lines. For added versatility, the system is fully compatible with Telesis’ popular Merlin® software, which enhances functionality with intuitive tools for creating and managing marking layouts.

Beyond its exceptional functionality, the BenchMark® 320 is backed by Telesis’ renowned global network of sales and service professionals, offering support and expertise wherever it’s needed. Telesis even offers a free part-marking evaluation—simply send in a part, and a marking expert will ensure that the BenchMark® 320 is the right solution for your needs. From its low operational costs and high reliability to its precision and ease of integration, the BenchMark® 320 with iZONIT™ sets a new standard for electric dot peen marking systems, empowering businesses to “Make Your Mark” with confidence and clarity.

The BenchMark® 320 is an affordable yet powerful dot peen marking system, ideal for low-volume operations that still require high precision and reliability. Its plug-and-play setup ensures quick and effortless installation, while its compact and ergonomic design makes part loading and positioning easy. Built for durability and consistent performance, the BenchMark® 320 is perfect for businesses looking for a cost-effective entry into permanent marking.

With a 100 mm x 150 mm (4.0 in x 6.0 in) marking area, the BenchMark® 320 can engrave text, graphics, serial numbers, logos, 2D matrix codes, and QR codes

on a variety of materials, including metals and most plastics. It is available in both vision and non-vision models, allowing for precise marking placement and real-time quality verification. Whether used as a standalone unit or integrated into a production line, this marker adapts to diverse manufacturing needs with ease and efficiency.

Complete your System

Our BenchMark320® Dot Peen Laser pairs with the following Telesis enclosures, workstations, and accessories to provide you with a complete end-to-end marking system.