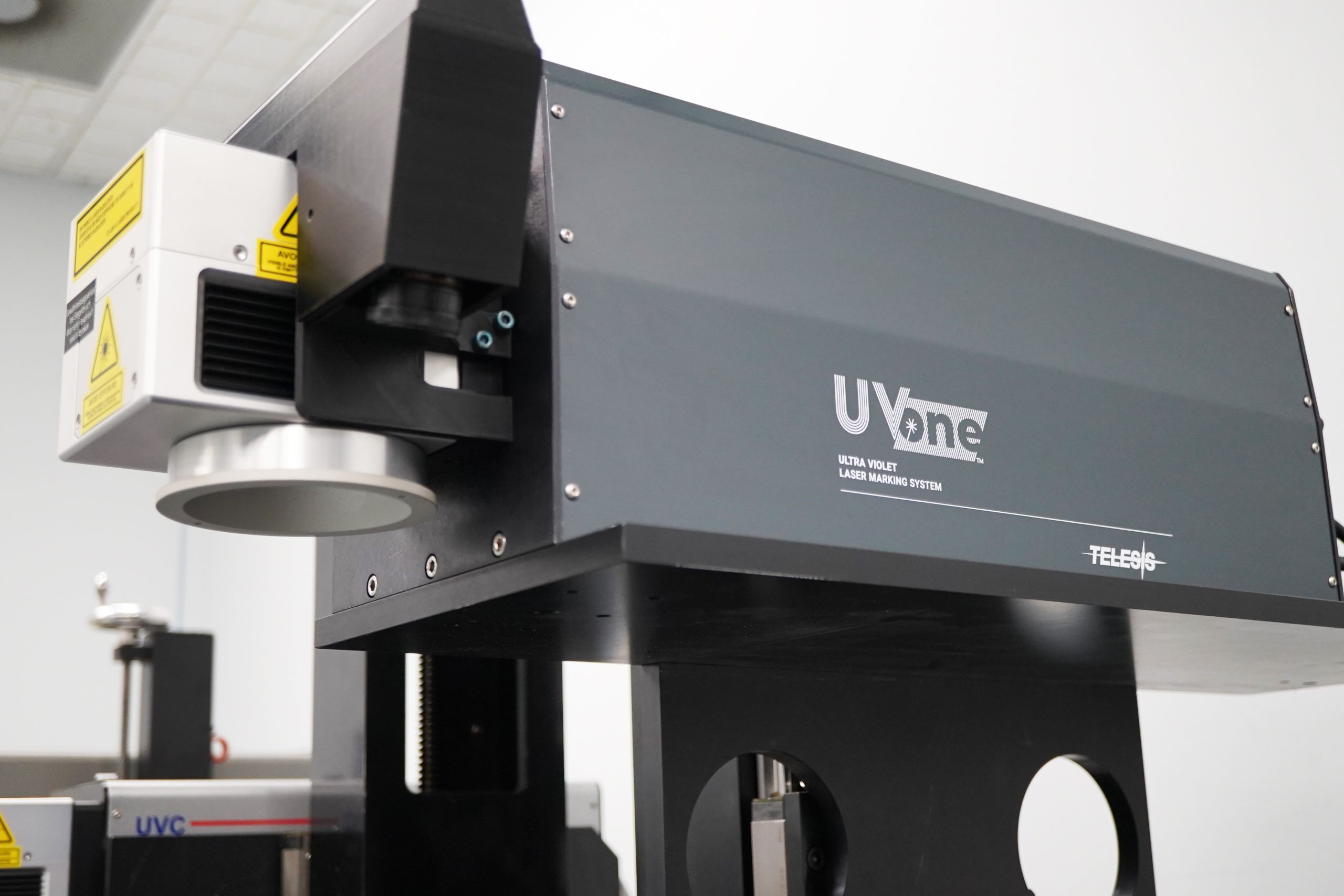

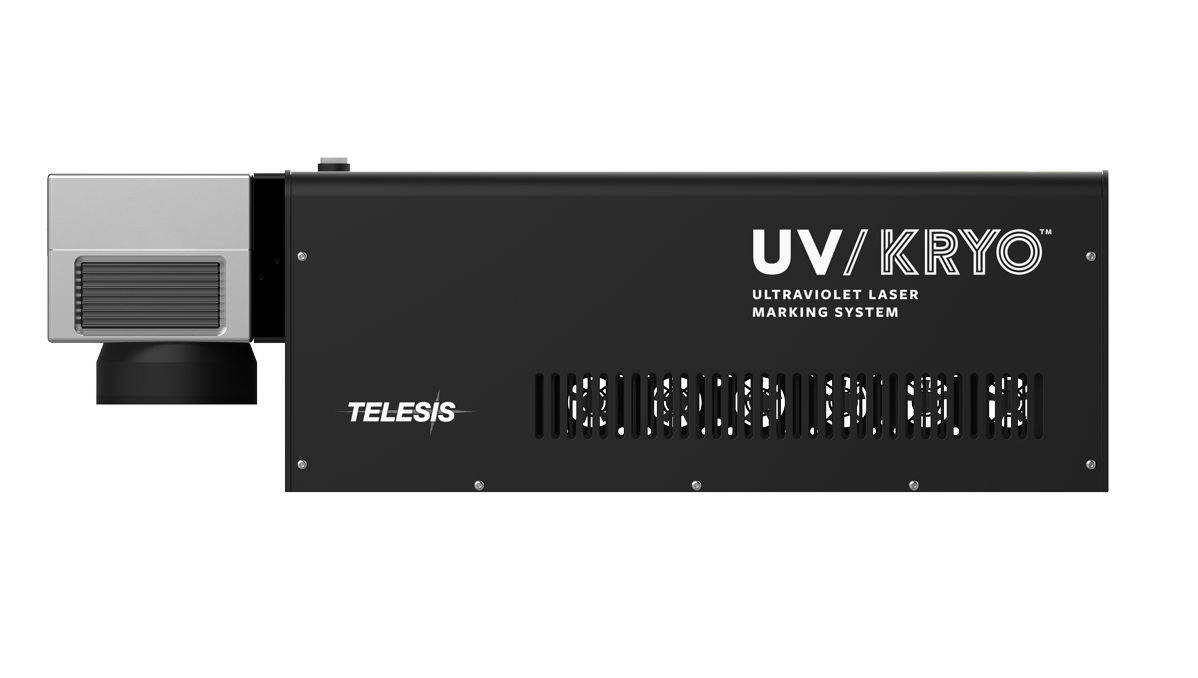

Cold Marking Technology

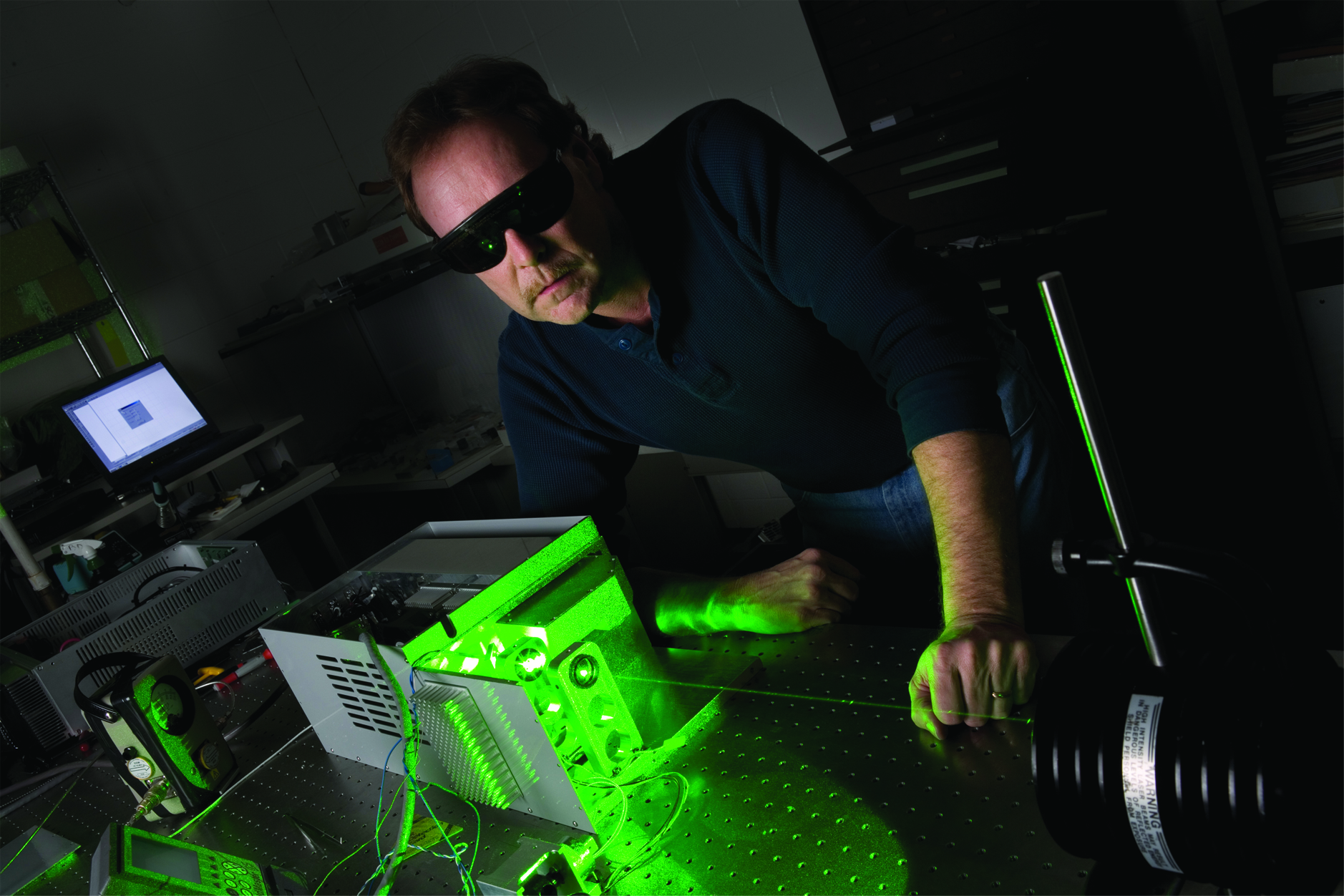

Unlike thermal laser markers, which use heat to melt or vaporize the material, cold laser markers operate at a shorter wavelength. This high-energy beam initiates a photochemical reaction that breaks molecular bonds directly within the substrate.

This process, known as photoablation, allows for the removal of material or a change in its color with a negligible heat-affected zone (HAZ). The result is a clean, crisp and permanent mark that leaves the surrounding material undamaged.