Understanding Laser Coding

Understanding Laser Coding

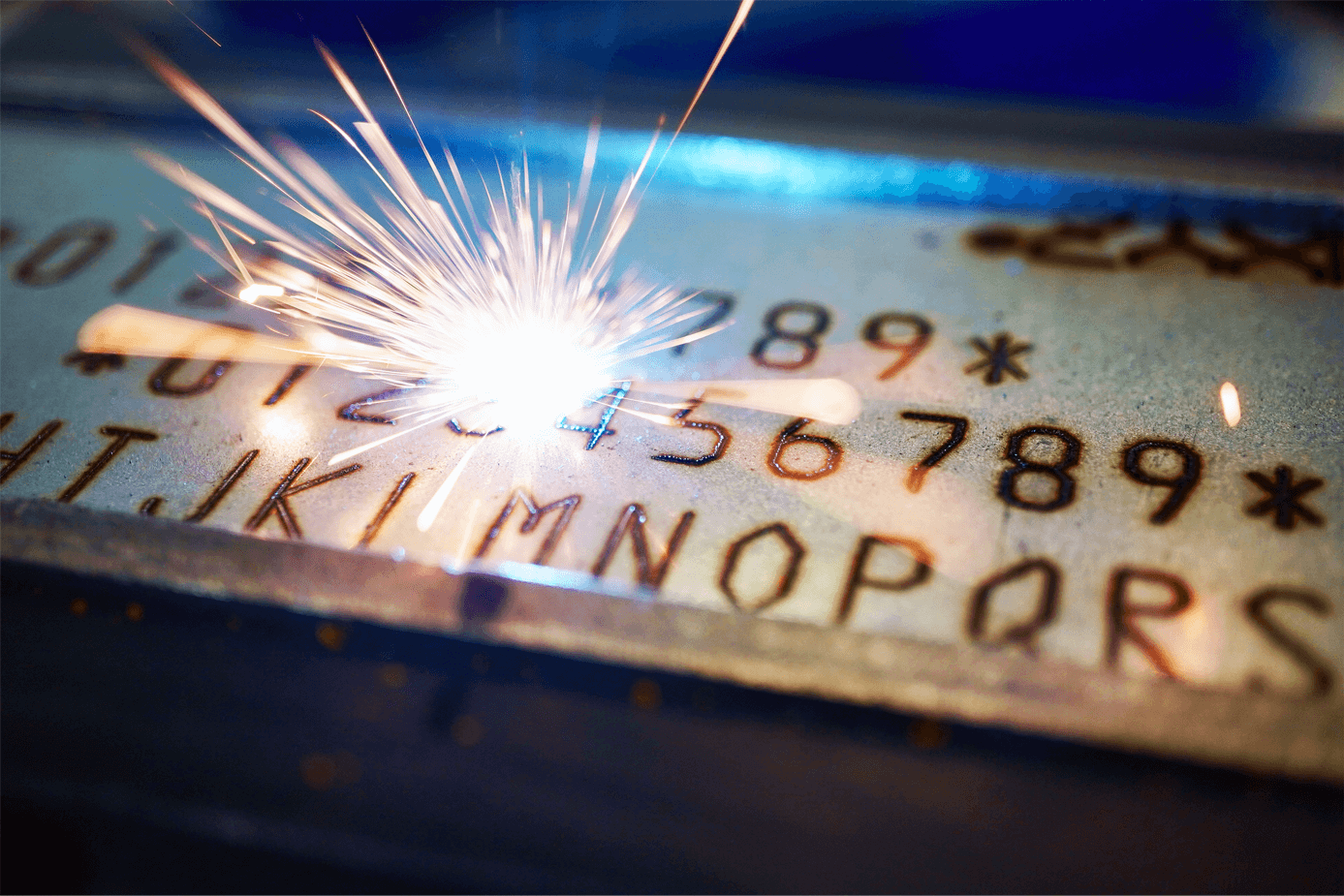

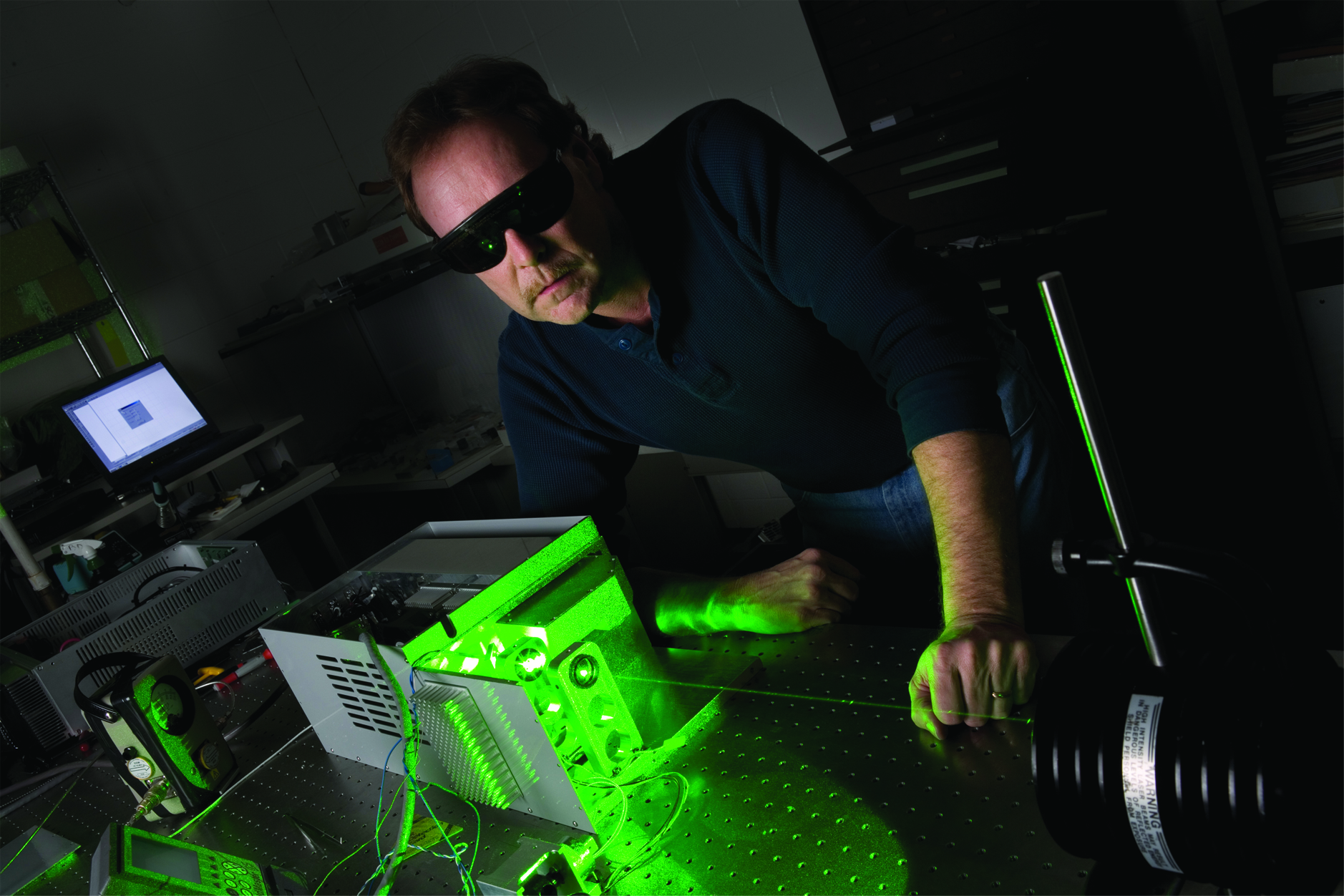

Laser coding is a noncontact process that uses a focused beam of light to create a permanent mark on a material’s surface. The intense laser energy alters the substrate, resulting in a high-quality, legible mark while maintaining the component’s structural integrity.

You can use this technology to create different types of marks, including:

- Alphanumeric characters: For serial numbers, expiration dates and lot codes.

- Barcodes and 2D codes: QR, UID, GS1 and UDI codes for traceability and quality control.

- Logos and graphics: For branding and clear product identification.

Our laser coders apply marks through engraving (removing material) and annealing (changing the material’s color using heat).