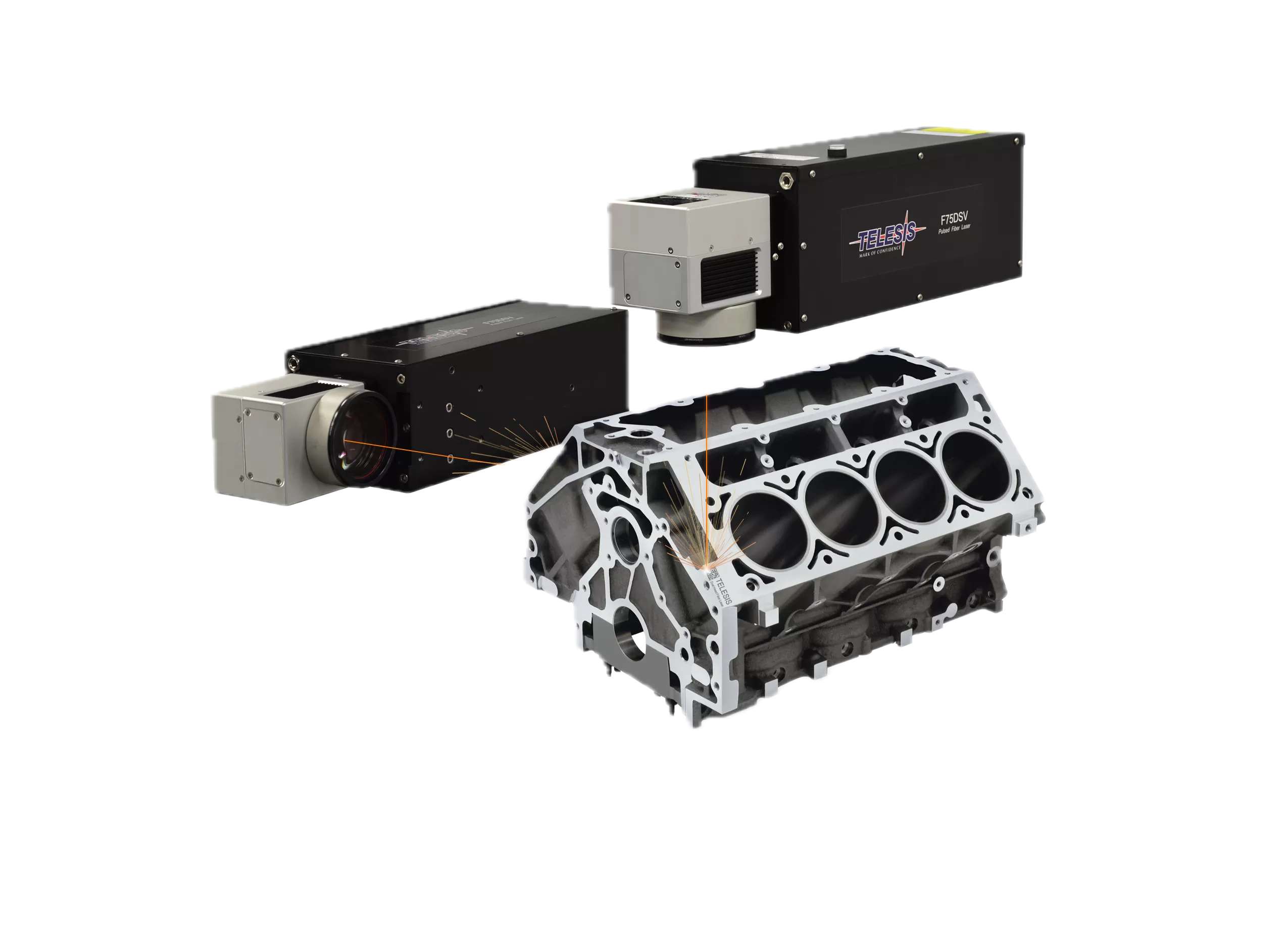

Our Dual-Head Laser System offers several benefits for your company and production processes. This laser engraver:

- Increases throughput: The dual-head system allows for faster laser engraving. You can increase your output in the same amount of time compared to laser systems with a single head.

- Improves reliability: Downtime is virtually eliminated because these systems have two separate lasers. If one laser needs service, you can continue to operate with the other laser head. This setup improves the reliability of your laser system, even when maintenance is needed.

- Saves floor space: Controlling the dual-head lasers from one controller reduces the space you need for your machines.

- Reduces part handling: The Dual-Head Laser Engraver reduces part handling by the operator, minimizing operational costs.

- Enhances laser performance: The dual-head setup combines two beams in the system using small and lightweight optical elements. Combining these two lasers creates a cross-polarized beam to make the cut width consistent regardless of cutting direction.