The TMP6100 automates essential marking functions, including serial numbers, time, date, and shift codes. Its easy PLC and host computer integration simplifies operation, while features like free software upgrades ensure the system stays up to date.

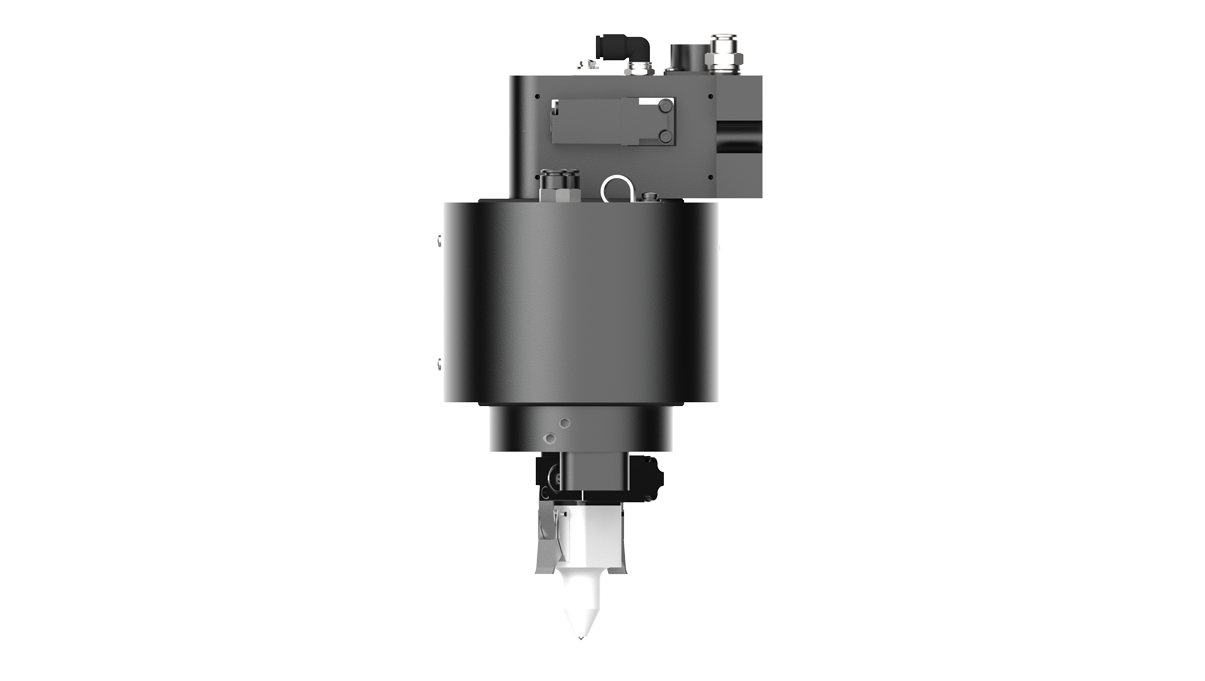

Unique Dot Peen Technology

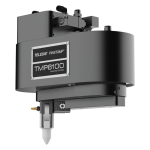

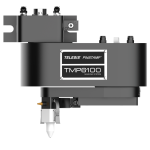

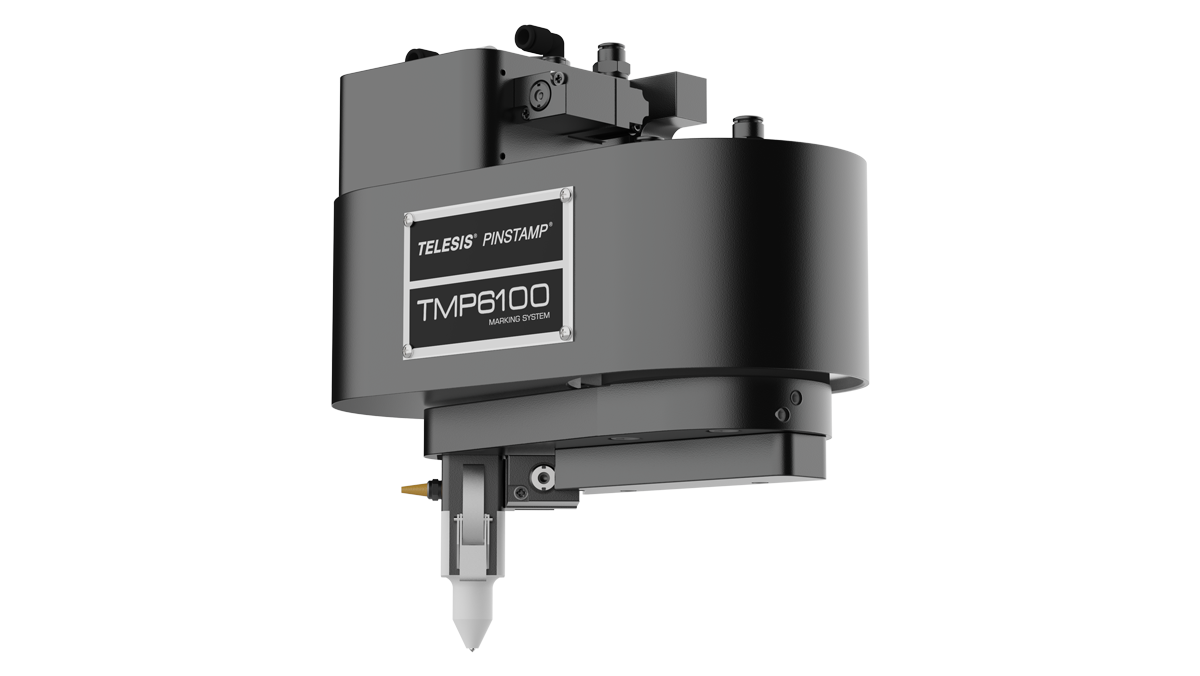

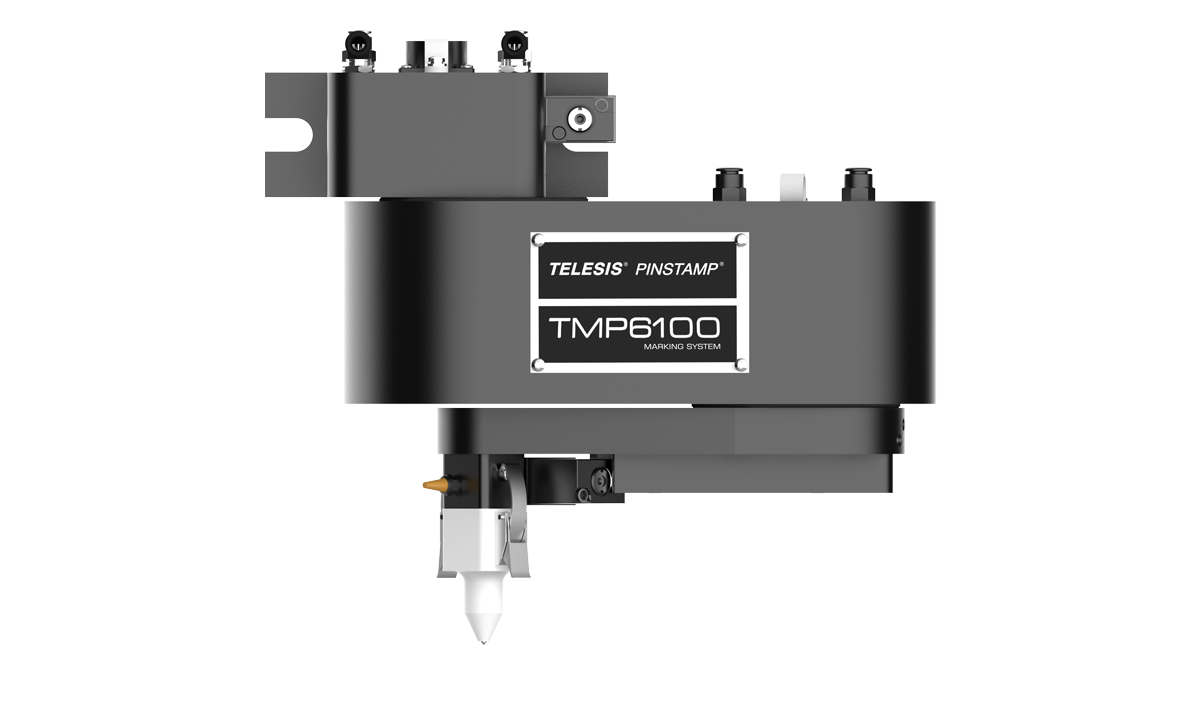

PINSTAMP® TMP6100 Dot Peen

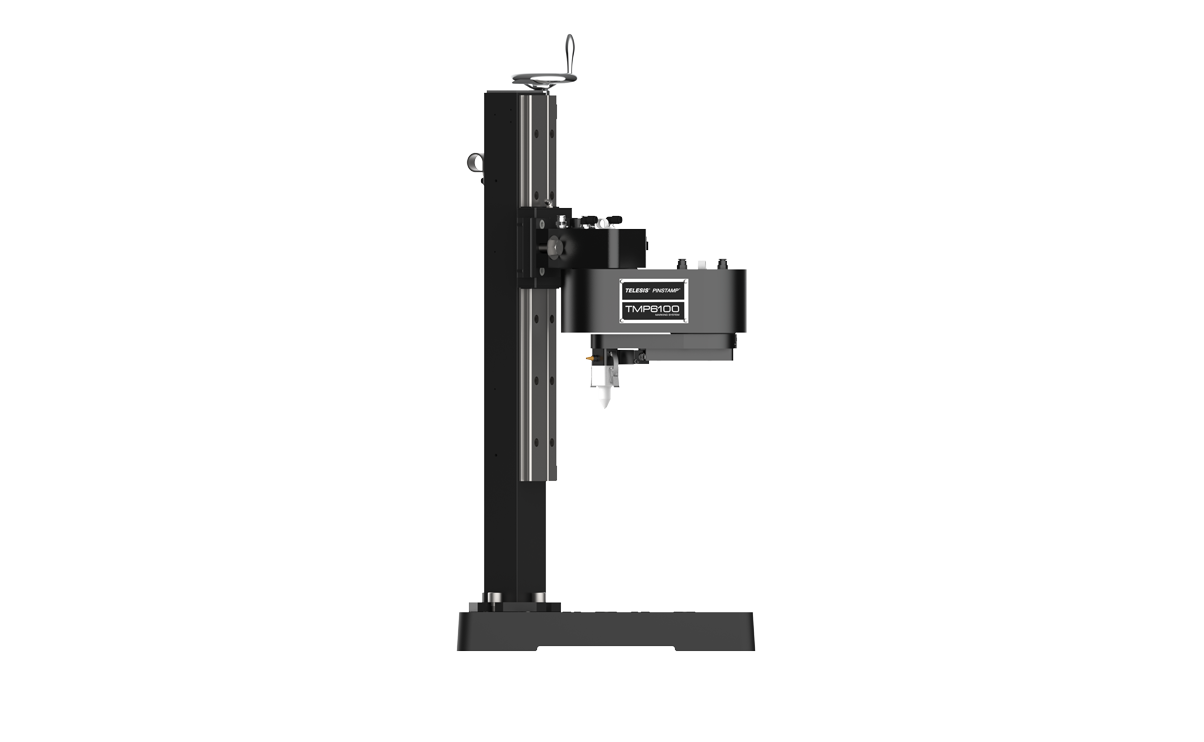

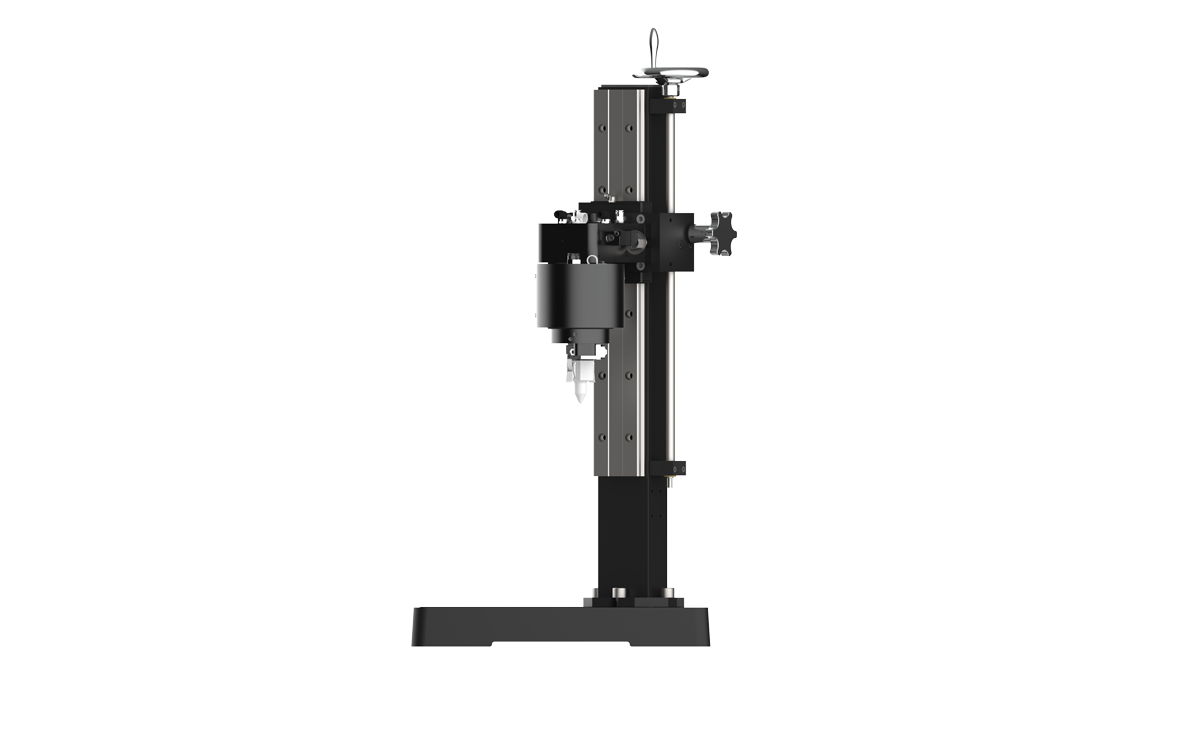

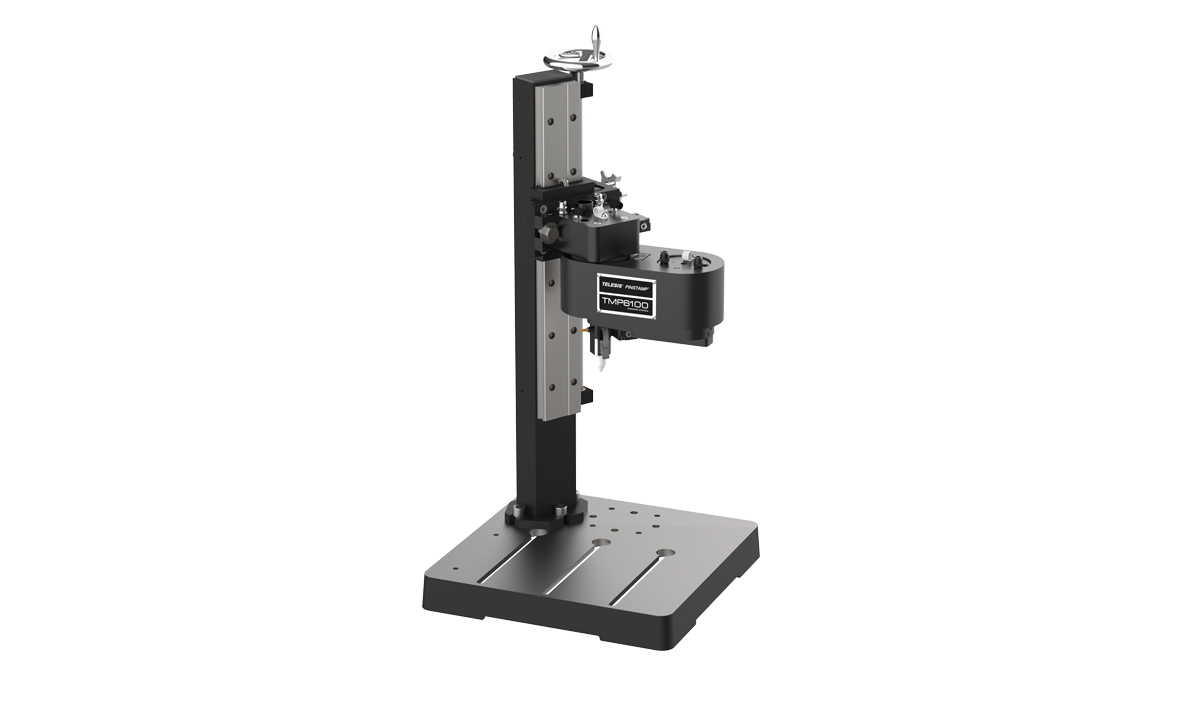

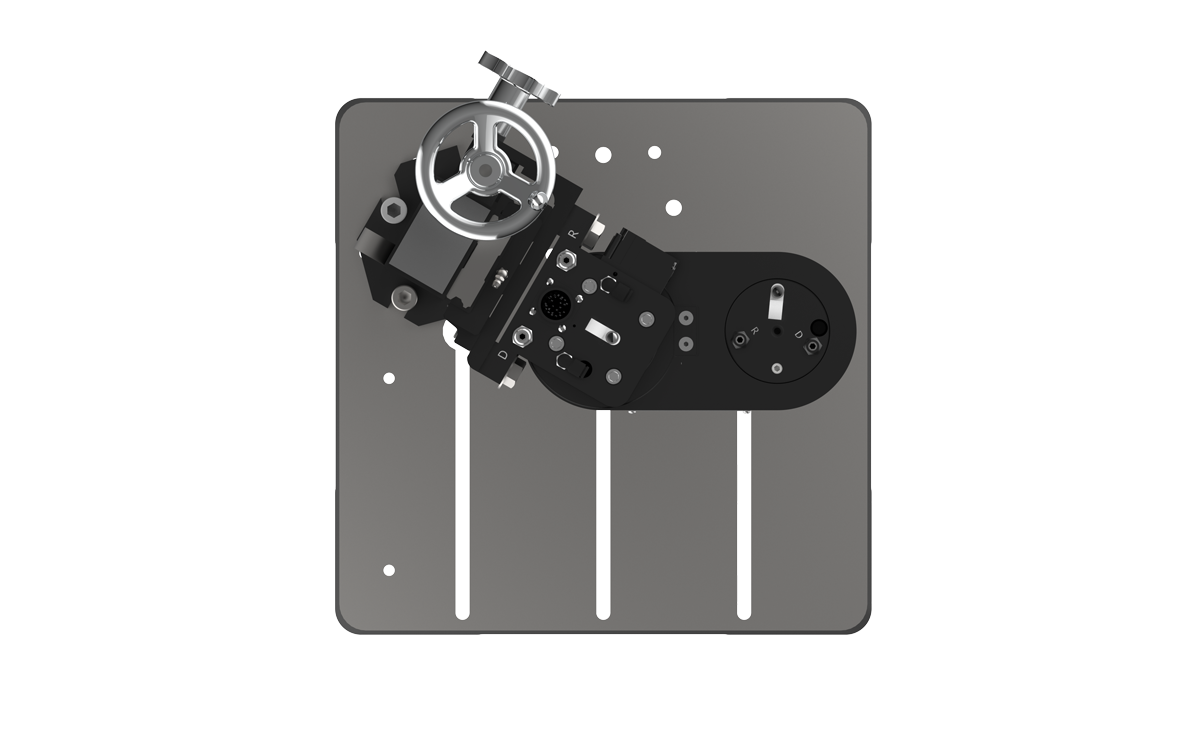

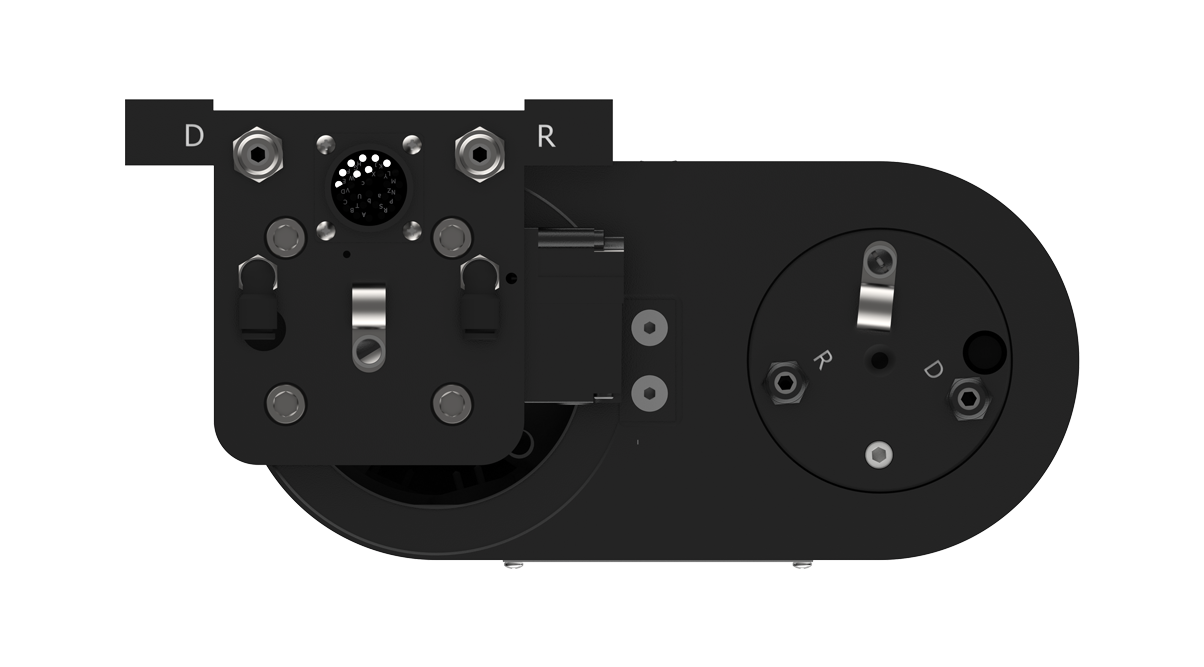

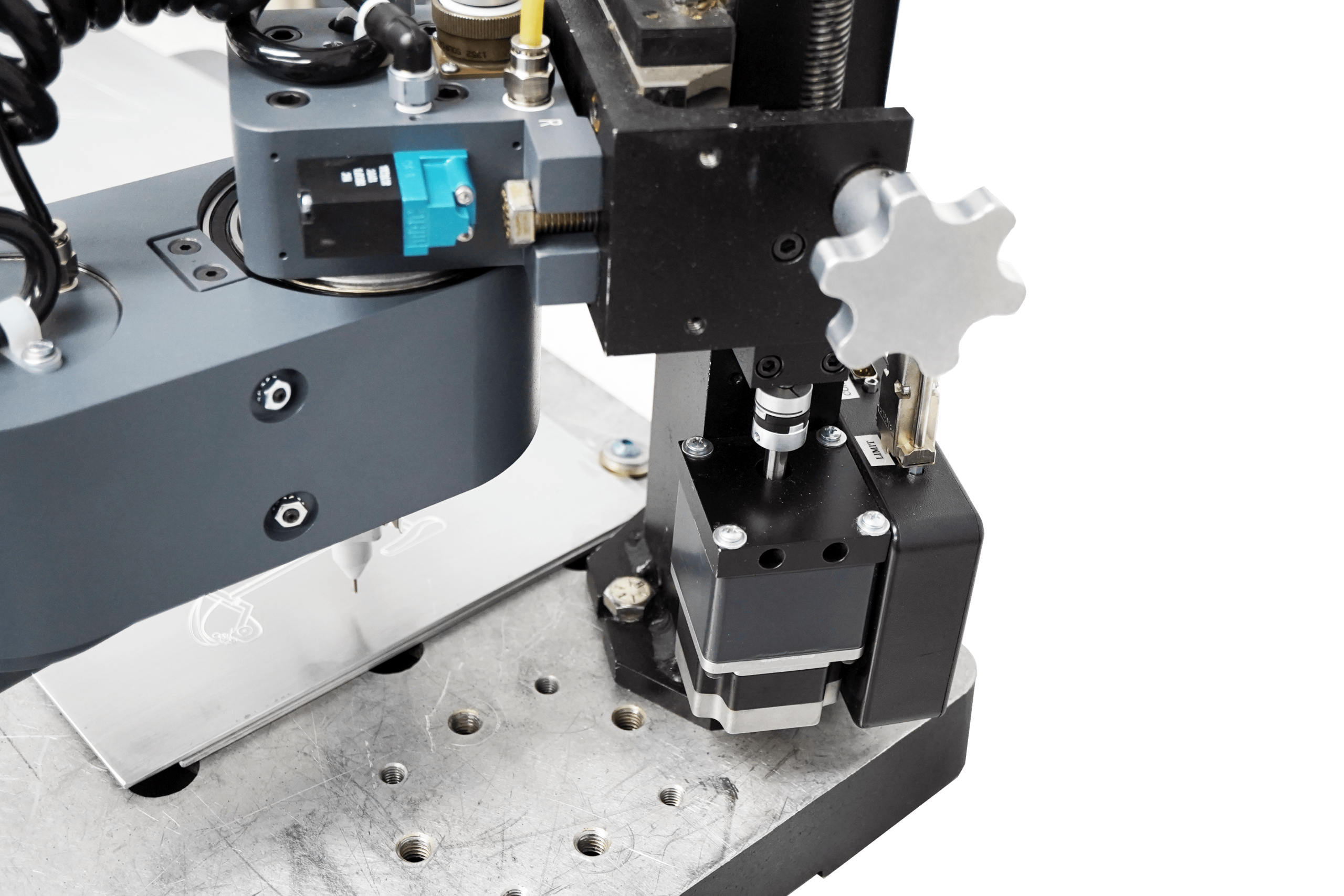

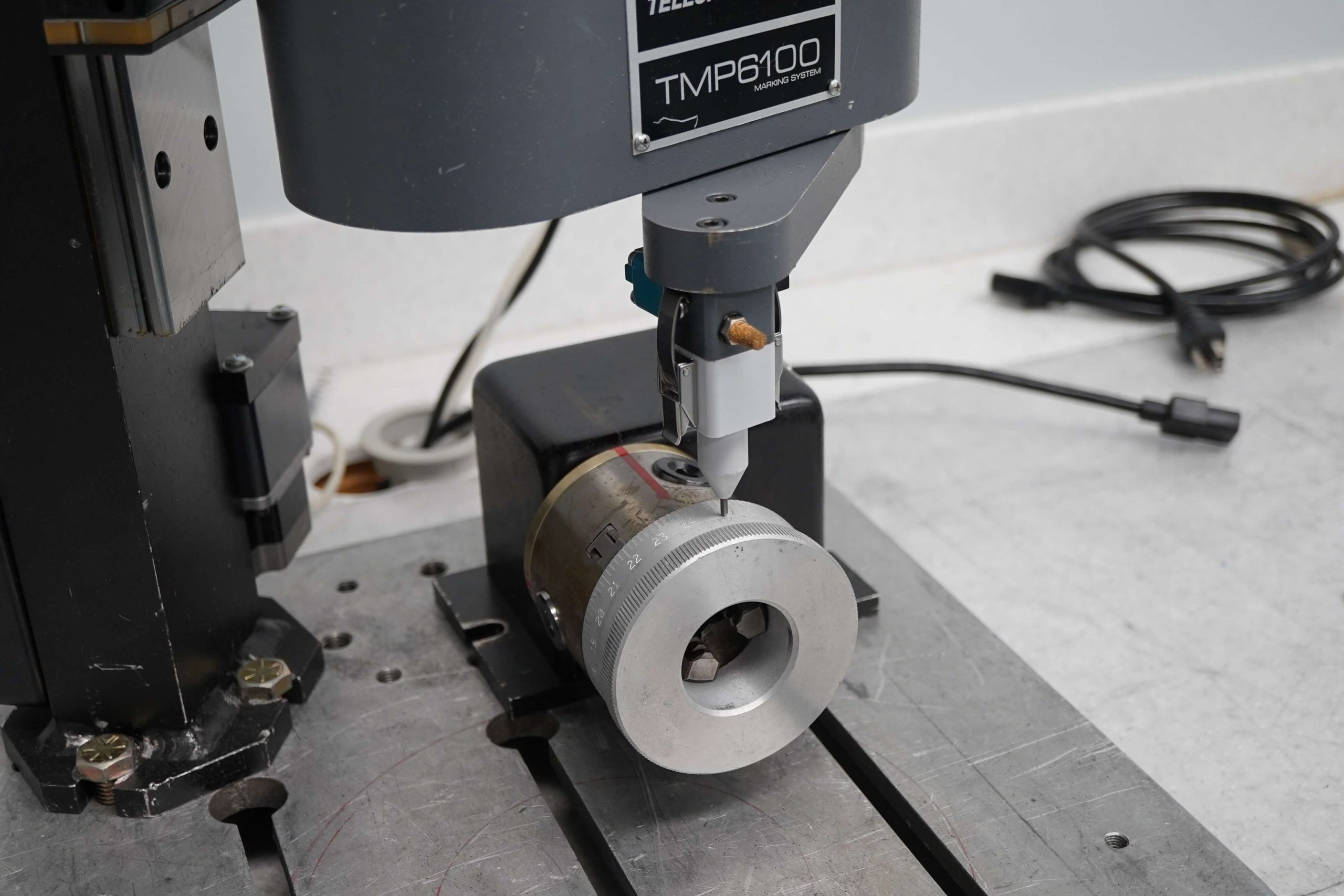

The Telesis PINSTAMP® TMP6100 is a robust dot peen marking solution, engineered for precise and efficient marking in industrial environments. With a robotic design, it offers unmatched accuracy, especially for cylindrical parts where a rotary device adds practicality. Built to endure tough manufacturing conditions, the TMP6100 integrates seamlessly into factory automation networks, making it versatile for diverse applications. Featuring an AutoSense motorized Z-axis for consistent pin stroke and critical standoff, the TMP6100 also offers electric models (TMP6100EAS) and a range of interchangeable marking pins for custom depths. Enhanced with options like rotary fixtures, panel-mount controllers, and easy software upgrades, the TMP6100 is the ideal choice for reliable, high-speed marking.

Request a Quote Download Product Catalog- Rugged, Low-Maintenance X/Y Platform: Built to endure tough conditions with minimal upkeep.

- Compact, Contaminant-Resistant Head: Perfect for production lines where reliability is critical.

- Material Versatility: Marks a wide range of materials, including plastics and hardened steel up to RC60.

- Easy Integration: Seamlessly interface with PLCs and host computers to streamline operations.

- Interchangeable Marking Pin Sizes: Adjust marking depth between 0.001″ to 0.018″ (0.03 mm to 0.34 mm)

- Floating Pin Technology: Handles surface irregularities for precise, consistent marking.

- Automated Marking Functions: Automatically generate serial numbers, time, date, and shift codes.

- Bar Code Scanner

- Foot Switch

- Marking Head Extension Cables

- Mounting Post

- Push Button Station

- Rotary Fixture

- System Computer

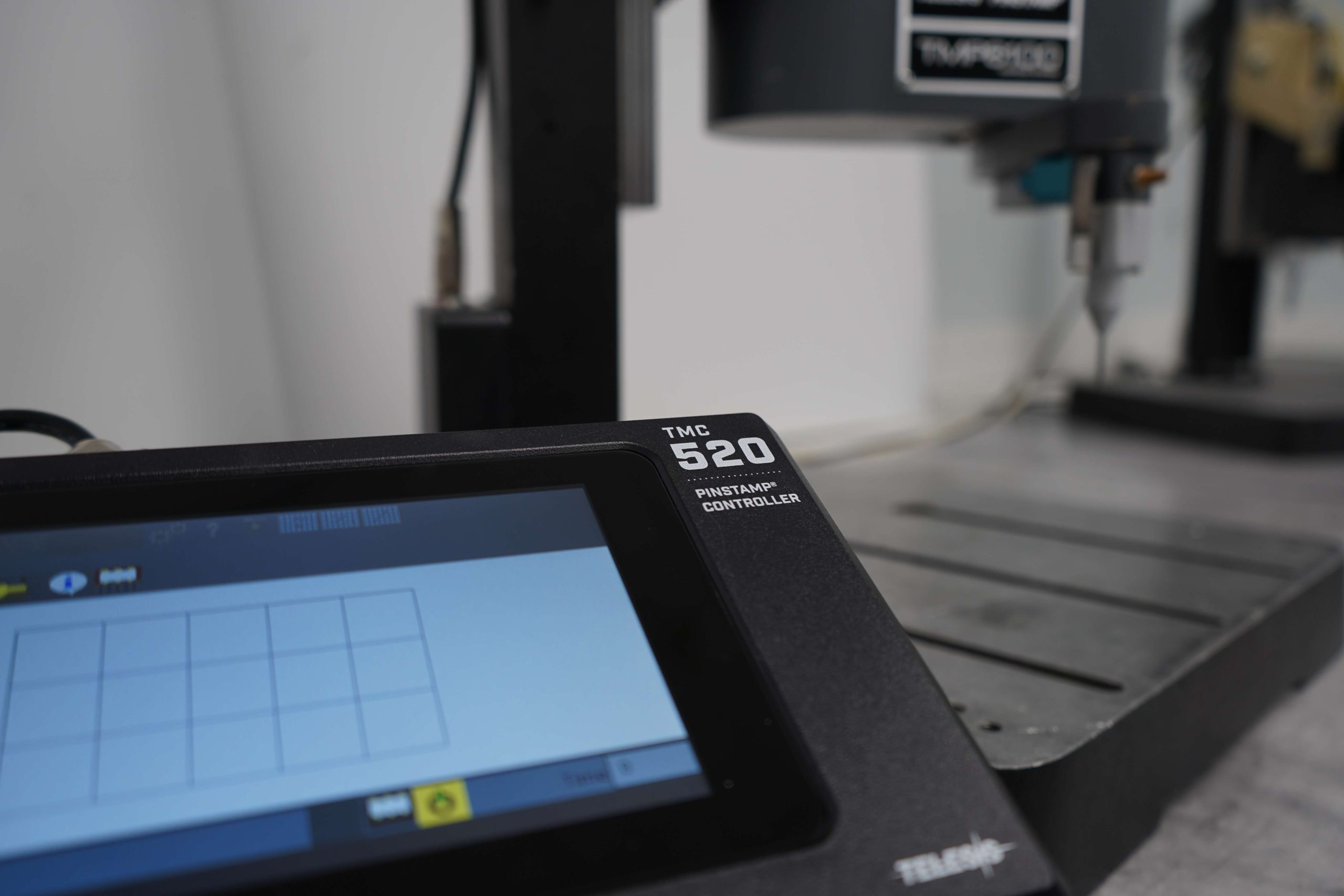

- Touch Screen Controller

- Various Marking Pins

Applications

Logo Marking

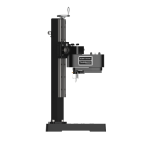

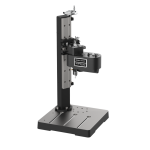

Programmable Mounting Post

2D Code Marking

Radial Marking

Specs

Marking Area

12 in x 6 in

304 mm x 152 mm

Material Compatibility

Soft plastics to hardened steel (up to RC60)

Marking Depth

0.001 – 0.018 in

0.03 – 0.34 mm

Connectivity

PLC, host computer interface

Controller(s)

TMC470 (Fixed Button)

Merlin III w/ PC

Available Models

TMP6100

TMP6100EAS (electric version)

Deliver Sharp, Reliable Marks with the Telesis TMP6100

The Telesis PINSTAMP® TMP6100 stands out as a premium dot peen marking system, engineered for precision and endurance in even the most demanding manufacturing environments. Known for its robust, robotic design, the TMP6100 delivers sharp, reliable marks on a wide range of materials, making it ideal for applications that demand permanent traceability.

With a specialized focus on cylindrical marking, the TMP6100 allows for efficient, high-quality markings on rounded surfaces. Its rotary device option optimizes production lines by adding efficiency and practicality, while the AutoSense motorized Z-axis provides unmatched consistency in marking depth and standoff distance. This automated adjustment minimizes manual intervention, reducing setup times and ensuring each mark meets the highest standards of clarity and durability.

Incorporating advanced Telesis technology, the TMP6100 is a versatile marking solution for today’s fast-paced, automated production lines. From its durable components to its user-friendly software, the TMP6100 sets the standard for efficient, high-quality marking across industries.

The Telesis TMP6100 is built for marking large parts and excels in cylindrical applications with the use of a rotary fixture. Its programmable AutoSense motorized Z-axis ensures precise pin stroke and critical standoff distance for consistent, high-quality marks. Ideal for automation, it integrates seamlessly into factory networks for improved efficiency and throughput.

Engineered with rugged, industrial-grade components, the TMP6100 withstands the harshest manufacturing environments. Whether marking soft plastics or hard metals, this model offers a variety of interchangeable pins to meet diverse application needs. Its electric version (TMP6100EAS) provides flexibility and sustainability for modern production lines.

The TMP6100EAS model extends flexibility with an electric option, ideal for quieter operation and enhanced precision. For intricate marking needs, choose from a variety of interchangeable marking pins, ranging from 0.001 to 0.018 inches, allowing for deep or delicate marks depending on your application. This system operates at impressive speeds, achieving up to two characters per second without sacrificing accuracy. Built-in features for generating serial numbers, date, time, and shift codes simplify marking workflows, making it an essential tool for applications requiring sequential or coded markings.

Integration into factory automation networks is seamless with the TMP6100’s easy PLC and host computer interfacing. The system offers IP/NEMA-rated controllers, panel-mount options, and software upgrades that ensure your marking process is always up-to-date with the latest capabilities. Whether for aerospace, automotive, or general manufacturing, the TMP6100 is equipped with programmable Z-axis mounting posts, rotary fixtures, and high-resolution marking at up to 200 dpi.

Complete your System

Our PINSTAMP ® TMP6100 Dot Peen Laser pairs with the following Telesis enclosures, workstations, and accessories to provide you with a complete end-to-end marking system.