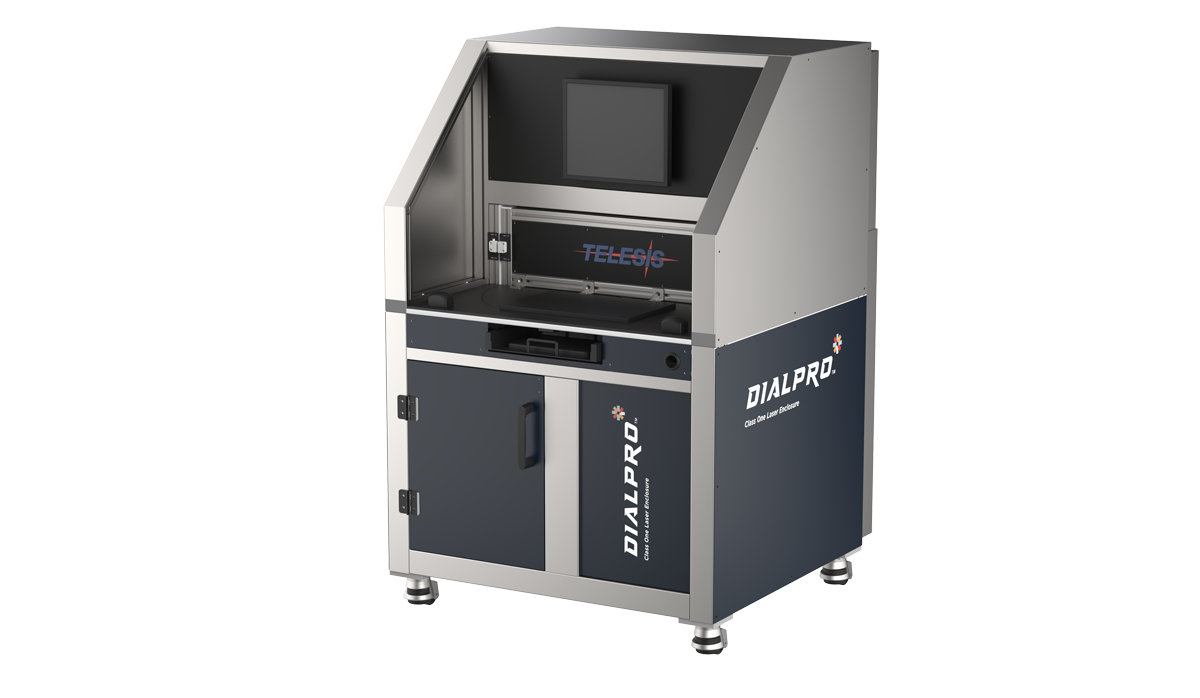

Engineered for ease of use, the DialPro™ provides a fast and straightforward part handling process. Its integration-friendly design, available with both front and overhead loading/unloading options, makes it simple to incorporate into existing production lines. A conveniently placed overhead monitor provides a clear view of control operations and code reading, saving valuable time during setup and operation.

For enhanced accuracy and speed, the optional iZONIT™ laser marker vision system can be integrated to optimize mark positioning and ensure flawless 2D code reading, delivering a new level of marking precision and quality assurance.